Macromolecular resin lens with high refractive indexes and preparation method thereof

A polymer resin, high refractive index technology, used in glasses/goggles, instruments, optics, etc., can solve the problems of low refractive index, limited application range of materials, unsatisfactory comprehensive performance, etc., to improve the refractive index, reduce Weight, Efficiency Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

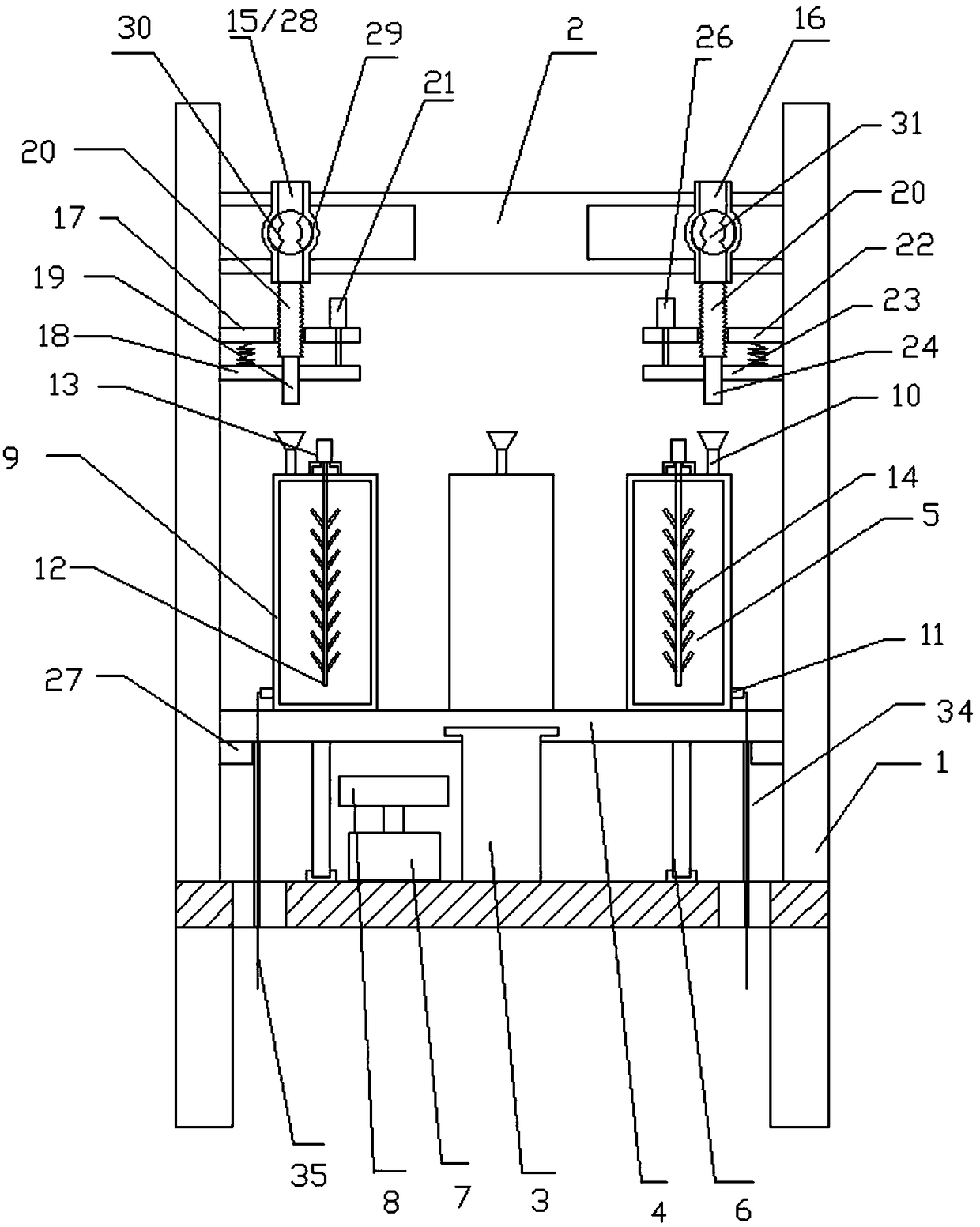

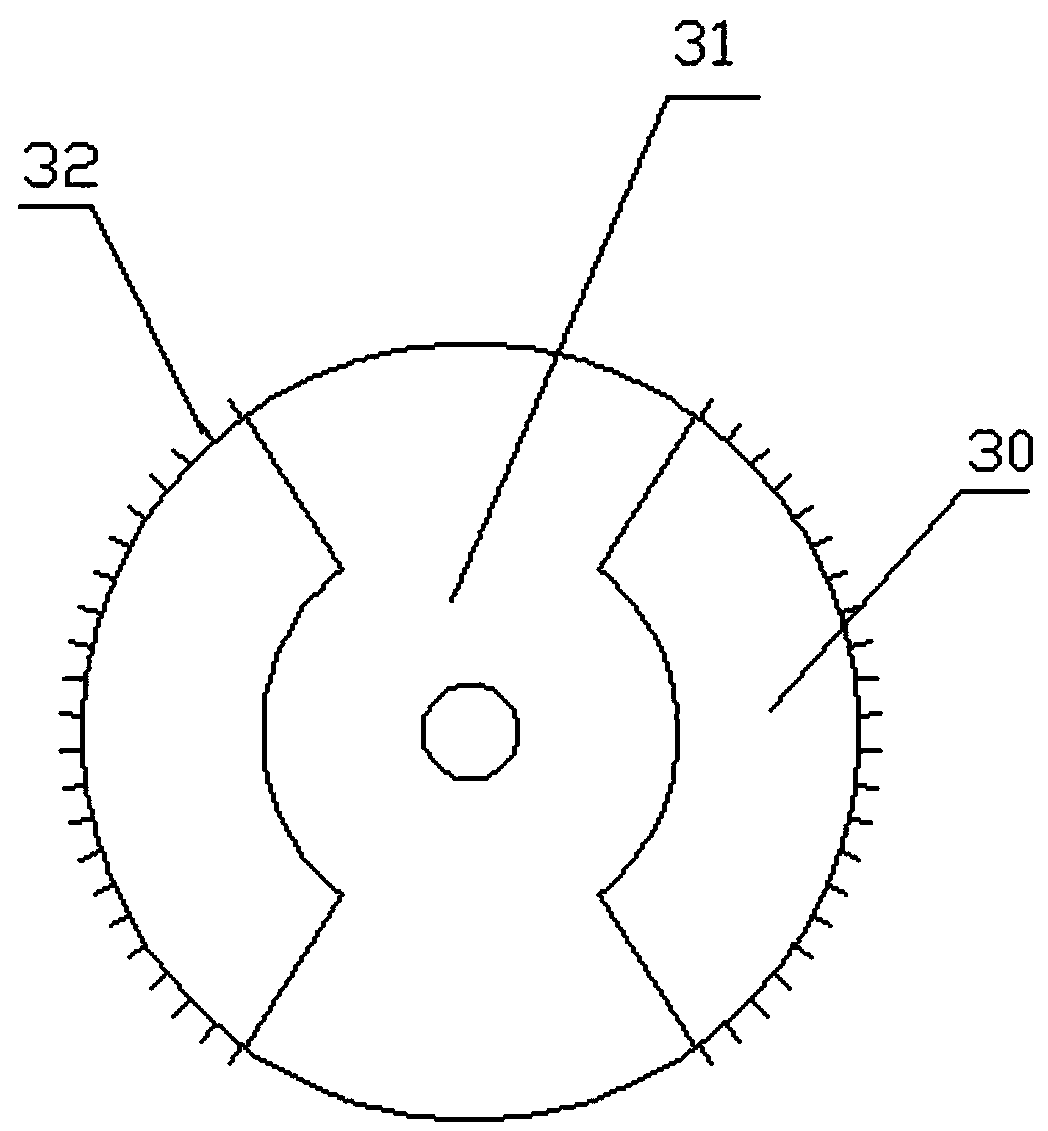

Method used

Image

Examples

Embodiment 1

[0044] A high-refractive polymer resin lens, the preparation method of which is:

[0045] (1) Dibutyl phthalate 15%, propylene alcohol 5%, isocyanate 30%, dibutyl tin dichloride 0.3%, photocuring initiator 0.5%, methyl styrene balance by weight percentage Add it into the dosing device, stir for 1 hour at a temperature of 30°C, lower the temperature to 20°C and then stir for 0.5 hour, and mix evenly to obtain a mixed liquid material;

[0046] (2) After the mixed liquid material is filtered, use nitrogen pressurization to inject the mixed liquid material into the mold, and seal the mold;

[0047] (3) The filled mold is cured once at 55°C for 4 hours, and the cured mold is opened to separate the mold and the formed lens;

[0048] (4) Trimming the formed lens to obtain a lens with precise diameter and high-gloss edge;

[0049] (5) The repaired lens is subjected to multi-groove ultrasonic cleaning, and the cleaned lens is subjected to secondary curing treatment in a curing furnac...

Embodiment 2

[0068] The polymer resin lens with a high refractive index described in Example 1 is different in that its preparation method is:

[0069] (1) Dibutyl phthalate 20%, propylene alcohol 15%, isocyanate 40%, dibutyltin dichloride 1.5‰, photocuring initiator 3‰, methyl styrene balance by weight percentage Add it into the dosing device, stir for 1 hour at a temperature of 35°C, lower the temperature to 25°C and then stir for 0.5 hour, and mix evenly to obtain a mixed liquid material;

[0070] (2) After the mixed liquid material is filtered, use nitrogen pressurization to inject the mixed liquid material into the mold, and seal the mold;

[0071] (3) The filled mold is cured once at 55°C for 4 hours, and the cured mold is opened to separate the mold and the formed lens;

[0072] (4) Trimming the formed lens to obtain a lens with precise diameter and high-gloss edge;

[0073] (5) The repaired lens is subjected to multi-groove ultrasonic cleaning, and the cleaned lens is subjected t...

Embodiment 3

[0076] The polymer resin lens with a high refractive index described in Example 1 is different in that its preparation method is:

[0077] (1) Dibutyl phthalate 25%, propylene alcohol 20%, isocyanate 50%, dibutyl tin dichloride 0.5%, photocuring initiator 1.0%, methyl styrene balance by weight percentage Add it into the dosing device, stir for 1 hour at a temperature of 40°C, lower the temperature to 30°C and then stir for 0.5 hour, and mix evenly to obtain a mixed liquid material;

[0078] (2) After the mixed liquid material is filtered, use nitrogen pressurization to inject the mixed liquid material into the mold, and seal the mold;

[0079] (3) The filled mold is cured once at 70°C for 3 hours, and the cured mold is opened to separate the mold and the formed lens;

[0080] (4) Trimming the formed lens to obtain a lens with precise diameter and high-gloss edge;

[0081] (5) The repaired lens is subjected to multi-groove ultrasonic cleaning, and the cleaned lens is subjecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com