Preparation method of poly(N-isopropylacrylamide) (PNIPAm) microgel and vanadium dioxide/silicon dioxide/PNIPAm composite microgel

A technology of microgel and micelles, which is applied in the suspension polymerization preparation of VO2/SiO2/PNIPAm composite microgel, and in the field of suspension polymerization preparation of PNIPAm microgel, which can solve the problem of poor dispersion of hydrogel and phase transition of PNIPAm Slow speed and other problems, to achieve the effect of easy operation, high output and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: a kind of PVP content is the preparation method of the polyisopropylacrylamide (PNIPAm) microgel of 1g / L, comprises following operation:

[0049] Dissolve 0.05g (1g / L) of PVP surfactant with a molecular weight of 58000 in 50ml of aqueous solution, transfer it to a 250ml three-neck flask, and keep it warm at 50°C for 30 minutes. After stable micelles are formed, add 1.25g (2.5wt %) NIPAm monomer and the corresponding ratio of Bis (such as 1wt% of the monomer mass) as a cross-linking agent, after the monomer and cross-linking agent are completely dissolved, the temperature is raised to 60°C, and the initiator KPS (0.01g / ml) is added dropwise PNIPAm microgels were synthesized by suspension polymerization and kept for 12 hours.

Embodiment 2

[0051] A kind of preparation method of the higher polyisopropylacrylamide (PNIPAm) microgel of PVP content, comprises following operation:

[0052] Dissolve 0.1g-0.2g (2-4g / L) (that is, 2g / L, 3g / L, 4g / L respectively) of PVP surfactant with a molecular weight of 58000 into 50ml of aqueous solution and transfer it to a 250ml three-necked bottle. Incubate at 50°C for 30 minutes until stable micelles are formed, add 1.25g (2.5wt%) NIPAm monomer and a corresponding proportion of Bis (such as 1wt% of the monomer mass) under nitrogen protection as a crosslinking agent, and the monomer and crosslink After the reagent was completely dissolved, the temperature was raised to 60° C., and the initiator KPS (0.01 g / ml) was added dropwise for suspension polymerization to synthesize PNIPAm microgels, which were kept for 12 hours.

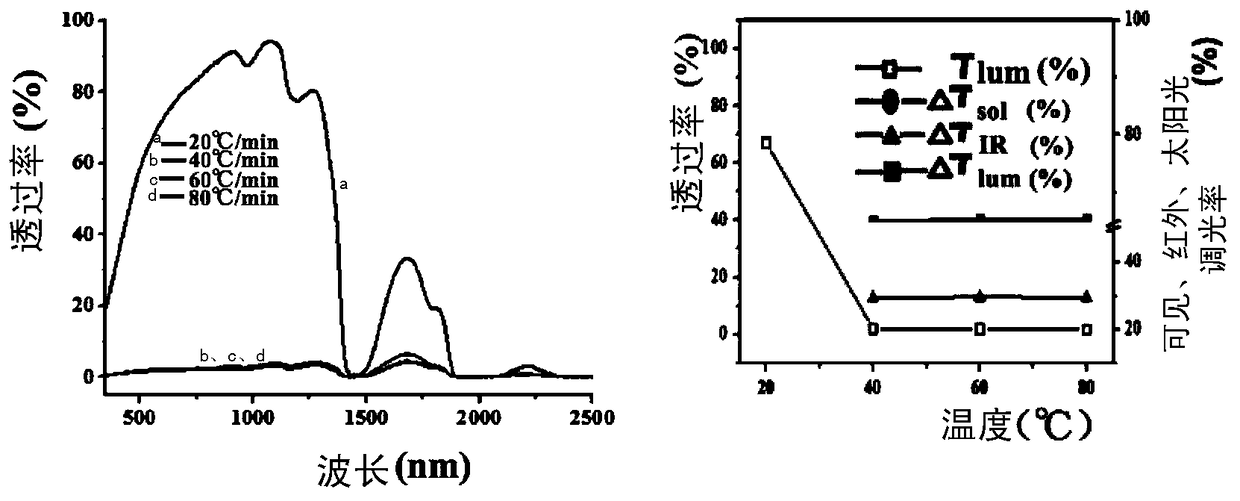

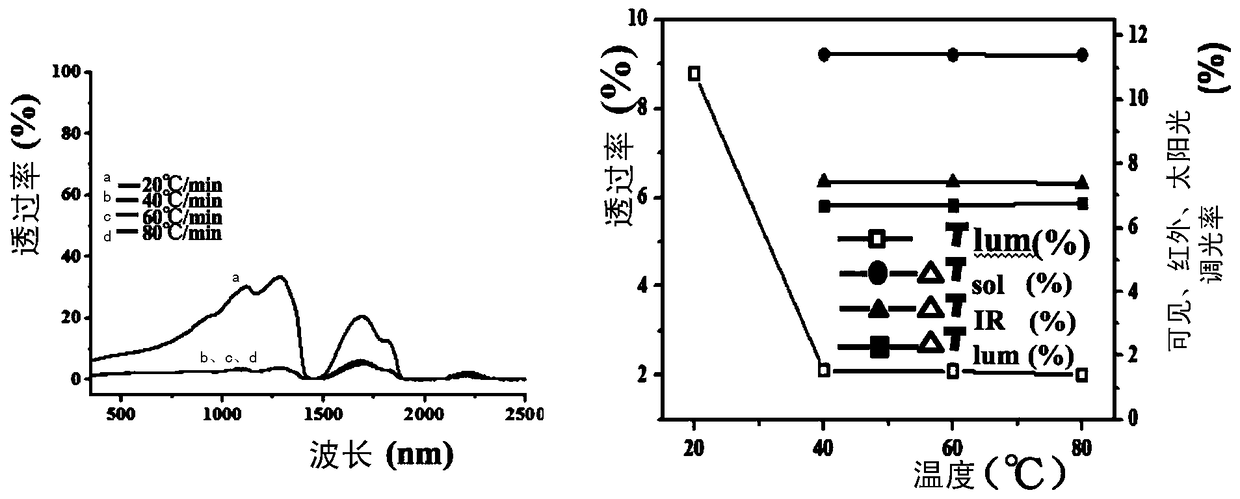

[0053] Heating the copper jacket using a homemade glass tank and water bath (see Figure 9 , where the glass jacket is used to hold the test sample and can be dir...

Embodiment 3

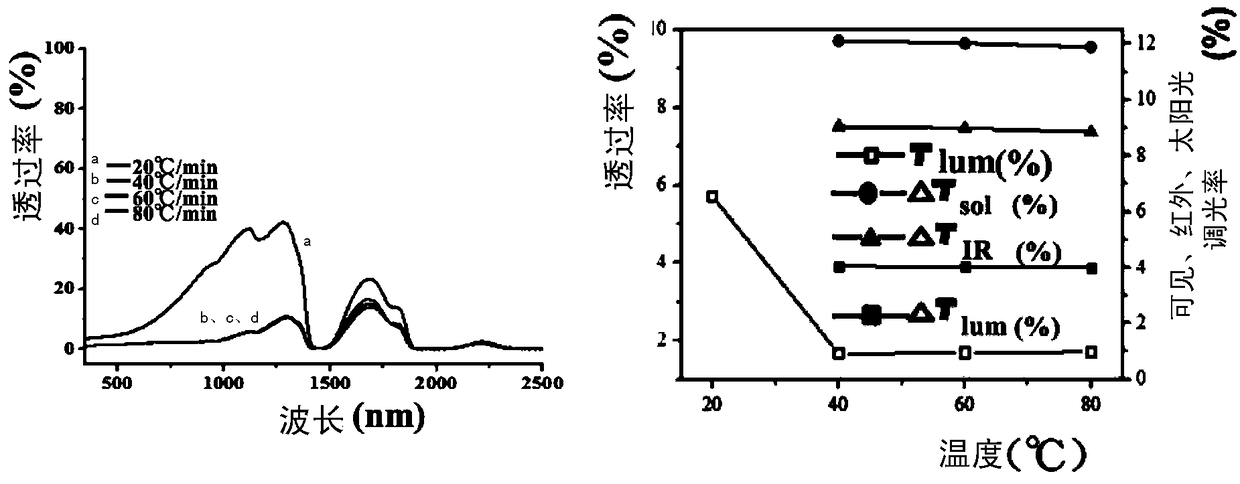

[0059] Embodiment 3: a kind of PVP content is the VO of 2g / L 2 @SiO 2 The preparation method of / PNIPAm composite material comprises following operation:

[0060] VO 2 @SiO 2 Preparation of powder: 0.05g VO 2 The powder (prepared by the hydrothermal reaction method) is uniformly dispersed in a 20ml glass reagent bottle (10ml ethanol, 20g zirconia balls with a diameter of 0.5mm), and is magnetically stirred at room temperature for about 8-10 hours at a speed of 600- 1000rpm. Then add 100 μl tetraethyl orthosilicate (TEOS) into the system and disperse uniformly for 1 hour. Slowly add 5 mL of ammonia water ethanol solution (ammonia water concentration 10%-20%) dropwise into the original system through a peristaltic syringe pump, react for 8 hours, and stop the reaction after the hydrolysis is completed. The product was washed twice with water and ethanol solution;

[0061] will VO 2 @SiO 2 powder to make VO 2 The content is 80.63mg / L, dispersed in the solution with PVP c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com