Self-driven compression type large temperature difference heat exchange unit

A heat exchange unit and compression technology, applied in the field of heating, can solve the problems of difficult installation, difficult implementation, poor economy, etc., and achieve the effects of small equipment volume, improved conveying efficiency, and high working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

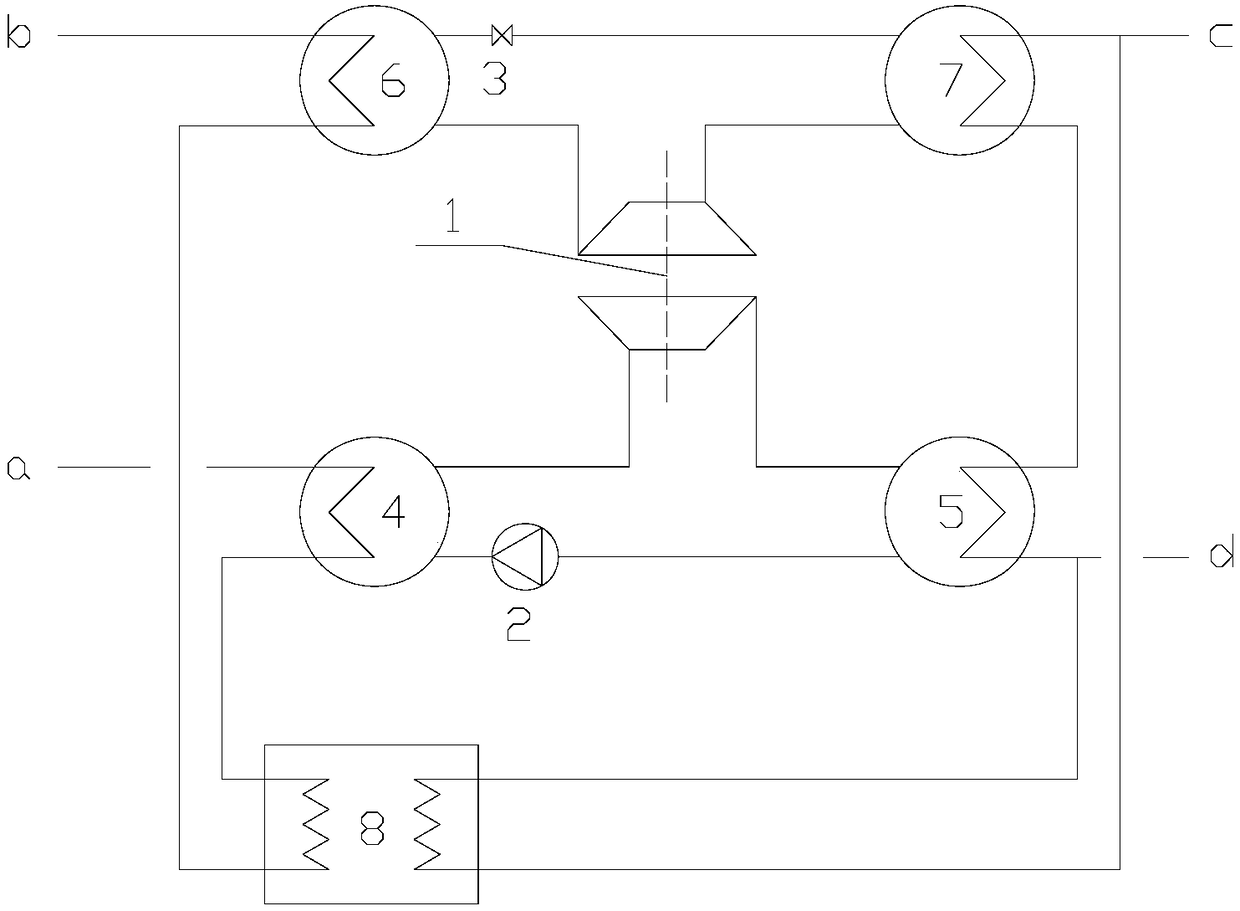

[0020] refer to figure 1 , The self-driven compression large temperature difference heat exchange unit includes a high-temperature evaporator 4, an expansion compressor 1, a high-temperature condenser 5, a working medium pump 2, a low-temperature evaporator 6, a low-temperature condenser 7, a throttle valve 3 and connecting pipelines. The primary hot water flows through the high-temperature evaporator 4, heat exchanger 8 and low-temperature evaporator 6 in turn. The primary hot water heats the working medium in the high-temperature evaporator to generate high-pressure steam. The high-pressure steam drives the expander to do work and then enters the condenser 5 for condensation. It is a liquid working fluid and releases heat to the secondary side. The condensed working fluid enters the high-temperature evaporator 4 through the working fluid pump 2; the cooled primary network hot water heats the working fluid in the low-temperature evaporator to generate low-pressure steam, which...

example 2

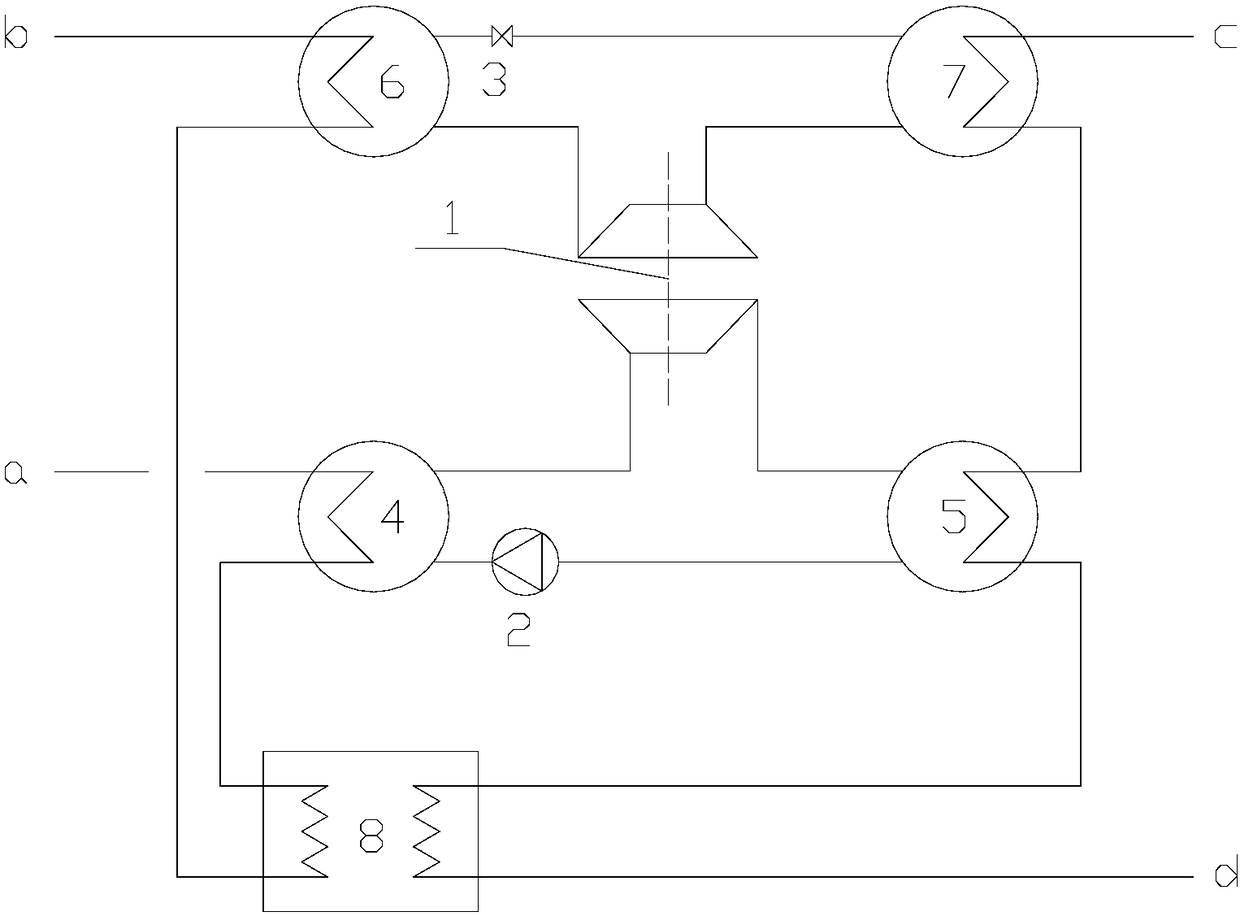

[0023] refer to figure 2 , the process on the working fluid side is the same as in Example 1, and will not be described again.

[0024] In this example, the hot water on the primary side enters the high temperature evaporator 4 , the heat exchanger 8 , and the low temperature evaporator 6 in sequence; the hot water on the secondary side enters the low temperature condenser 7 , the high temperature condenser 5 , and the heat exchanger 8 in sequence.

example 3

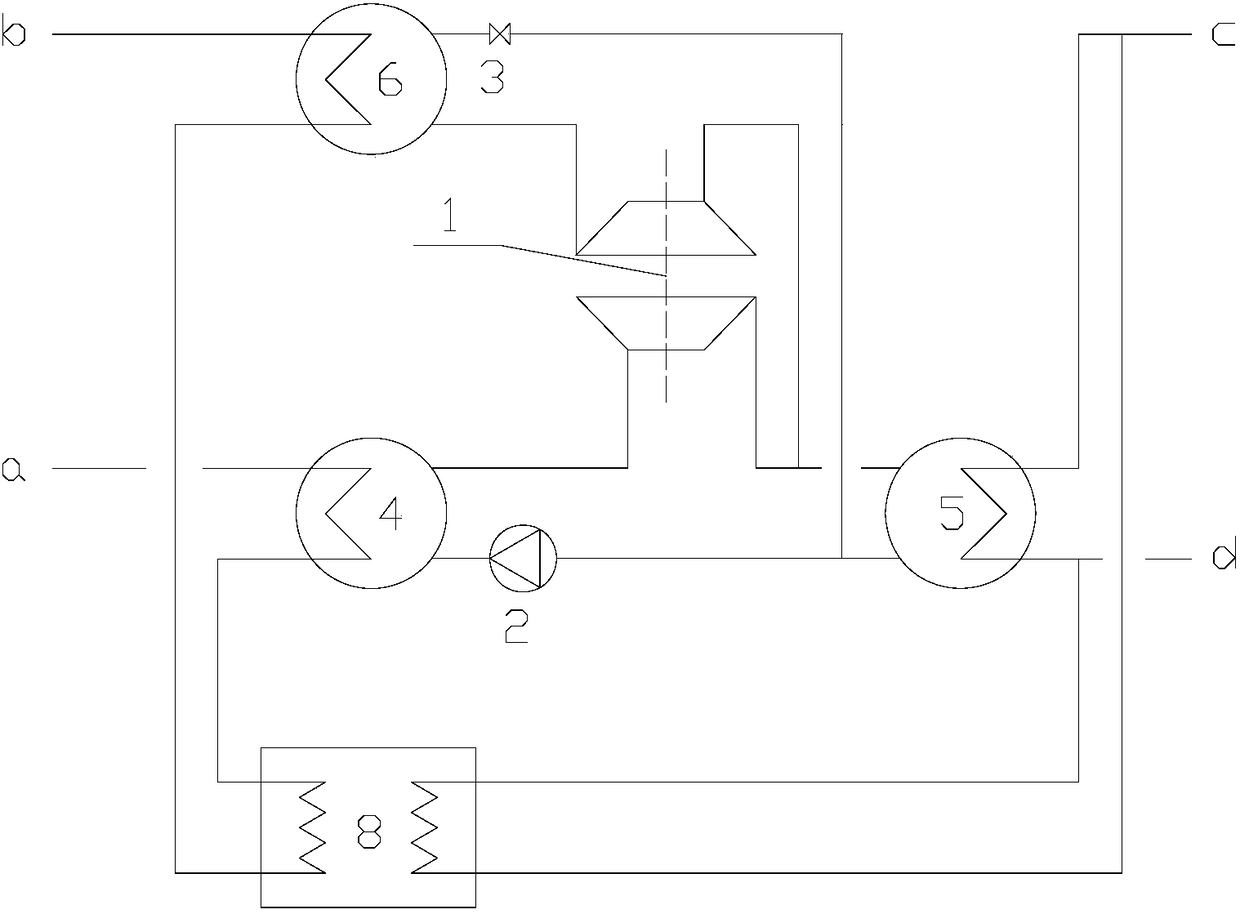

[0026] refer to image 3 , The self-driven compression large temperature difference heat exchange unit includes a high-temperature evaporator 4, an expansion compressor 1, a condenser 5, a working medium pump 2, a low-temperature evaporator 6, a throttle valve 3 and connecting pipelines. The hot water in the primary network flows through the high-temperature evaporator 4, heat exchanger 8 and low-temperature evaporator 6 in sequence. The hot water in the primary network heats the working fluid in the high-temperature evaporator to generate high-pressure steam, which drives the expander to do work and then enters the condenser 5 for condensation. It is a liquid working fluid and releases heat to the secondary side. The condensed working fluid enters the high-temperature evaporator 4 through the working fluid pump 2; the cooled primary network hot water heats the working fluid in the low-temperature evaporator to generate low-pressure steam, which is After compression, the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com