Geotechnical synthetic material straight shearing and drawing integrated testing device capable of exerting dynamic loads

A technology of geosynthetic materials and testing devices, which is applied in the direction of testing material strength by applying stable shear force and testing material strength by applying stable tension/compression, which can solve the problem of large space occupation, large difference in effect and equipment Problems such as low utilization rate, to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0036] The present invention will be described in detail below with reference to the accompanying drawings and examples.

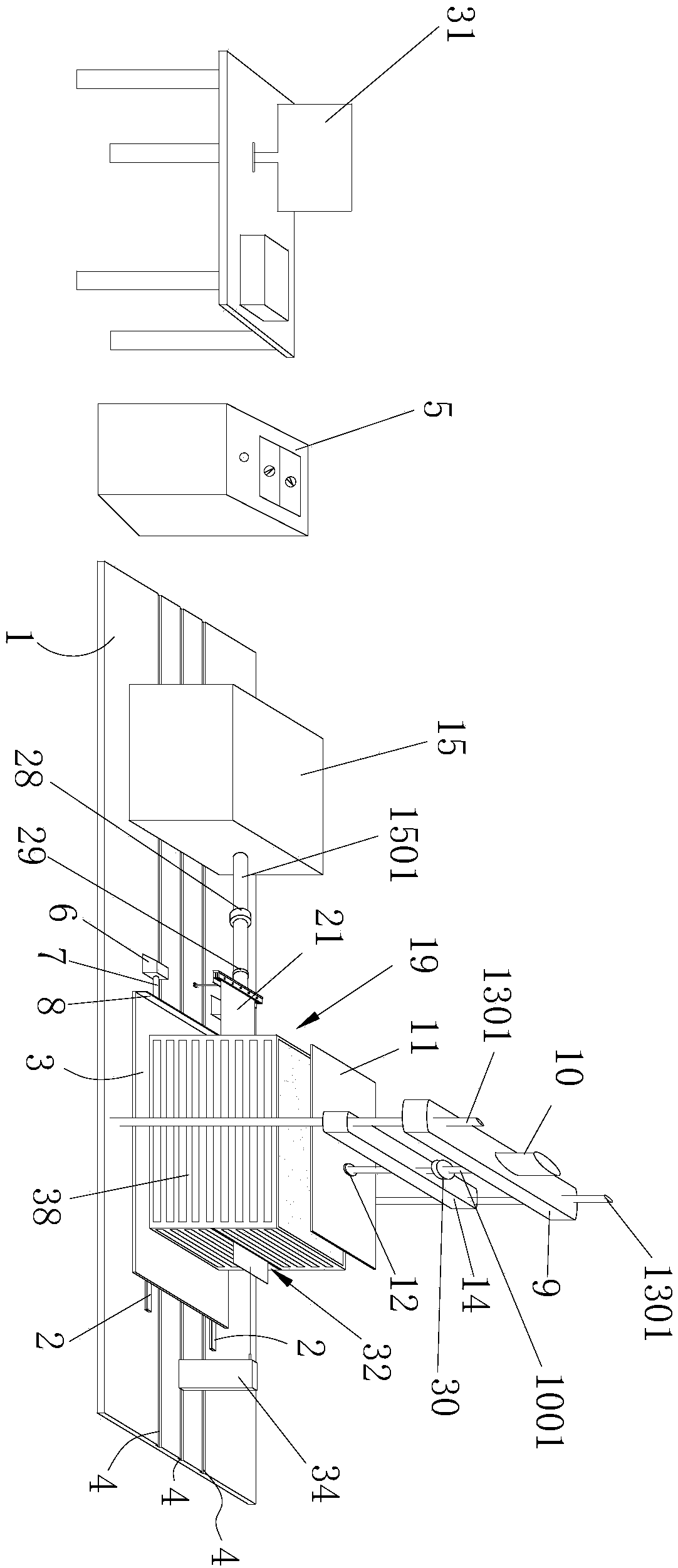

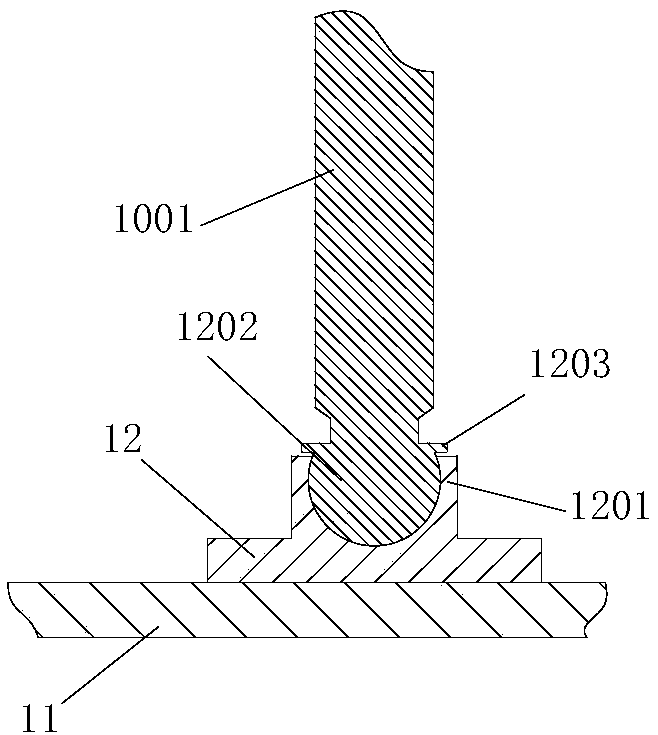

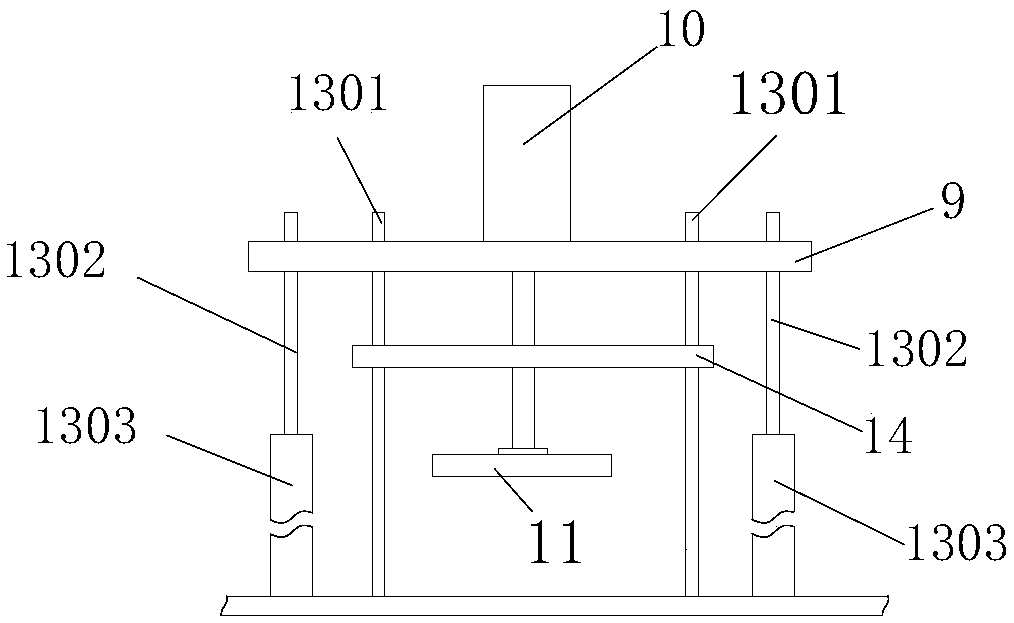

[0037] This embodiment relates to a geosynthetics direct shear and pull integrated test device that can apply dynamic loads, which includes a base with a horizontal moving platform, and a test box that is detachably connected to the horizontal moving platform. Geosynthetic material samples embedded by fillers are arranged in the box. The integrated direct shear and pull test device for geosynthetics that can apply dynamic loads also includes a horizontal load that is installed on one side of the test box and can output horizontal linear power to perform direct shear or pull tests on geosynthetics samples. Mechanism; there is a normal loading mechanism with a pressure-bearing plate above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com