Glass surface defect detection system and method

A defect detection, glass surface technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve problems such as weak anti-interference ability, high background requirements, harsh use scenarios, etc., to improve accuracy and prevent light Current, the effect of eliminating background interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

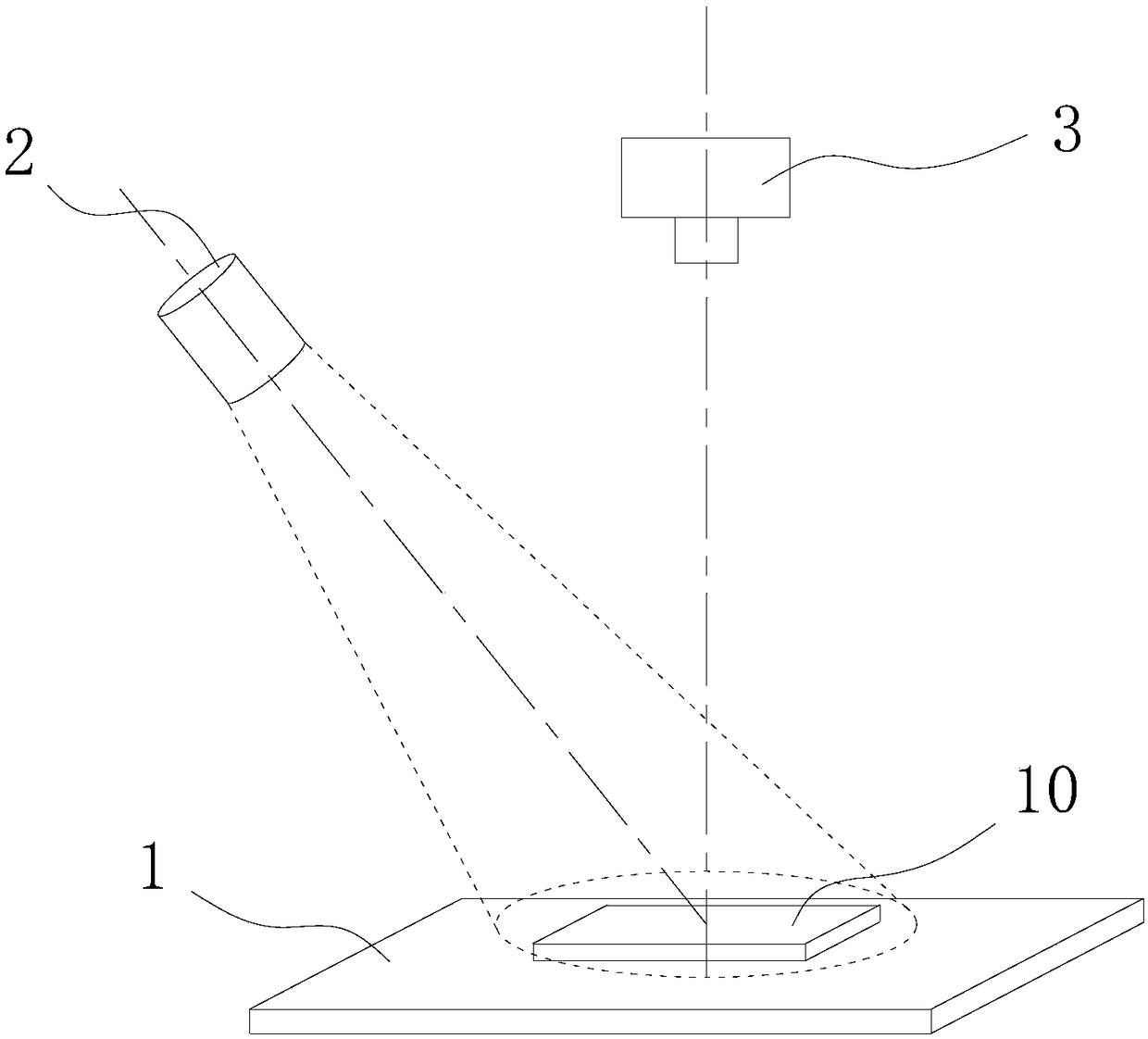

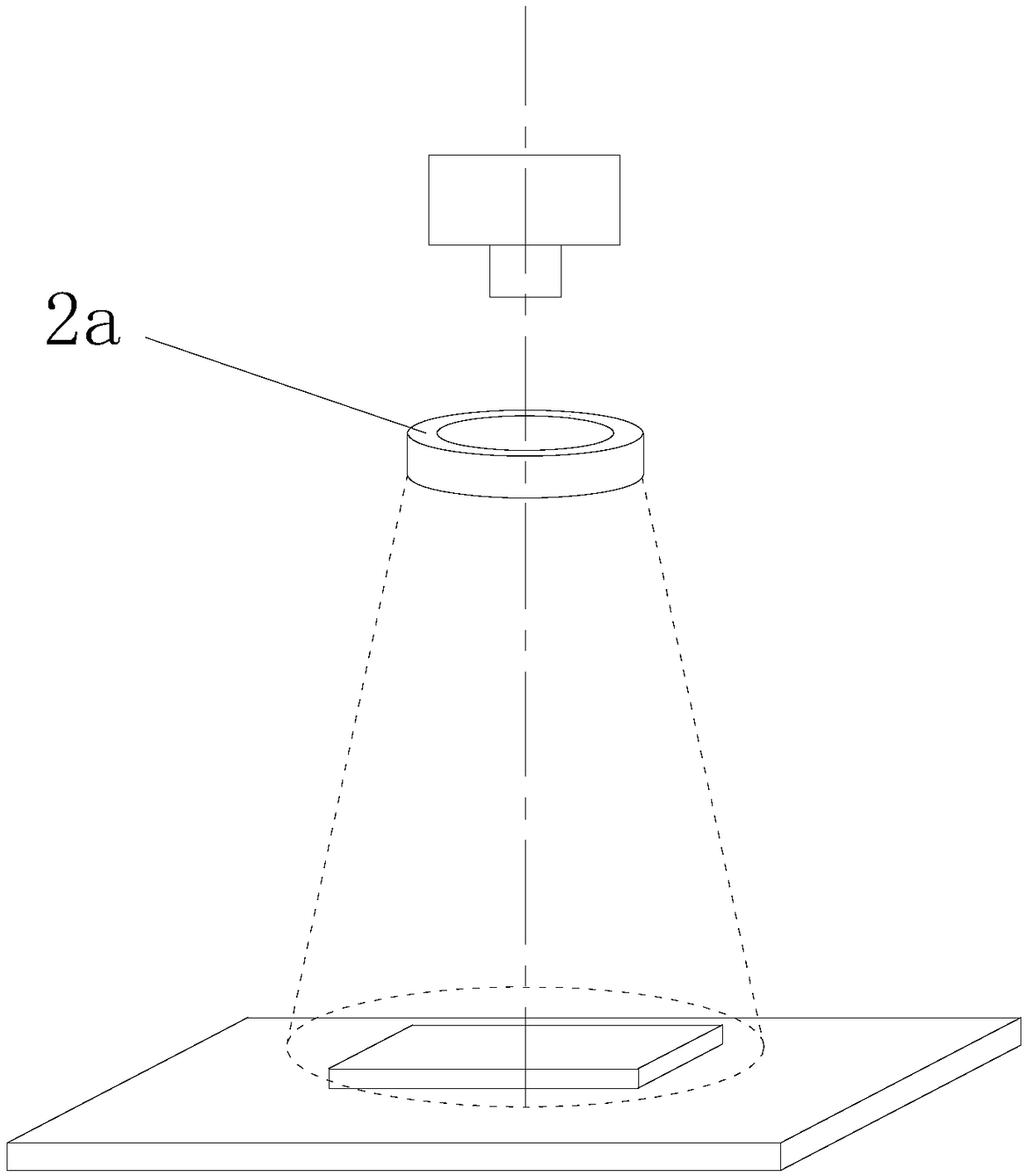

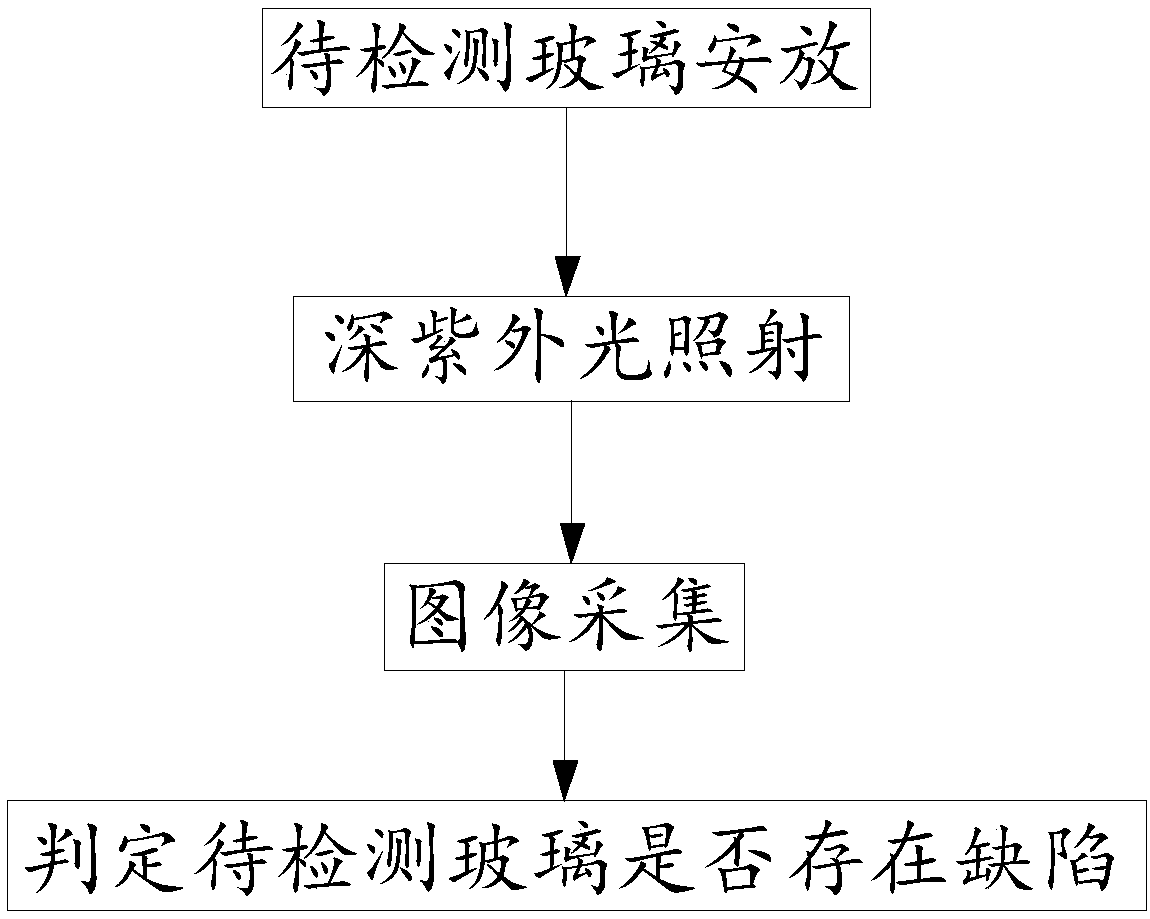

[0027] refer to figure 1 , the present invention provides a glass surface defect detection system, including a carrying platform 1, a deep ultraviolet light source 2 and a special camera 3, wherein the carrying platform 1 is used to support and place the glass 10 to be detected; the deep ultraviolet light source 2 emits deep ultraviolet light and The glass 10 to be inspected on the carrying platform 1 is irradiated obliquely; the special camera 3 is installed directly above the carrying platform 1 and facing the surface of the carrying platform 1 for image acquisition.

[0028] The brightness of the deep ultraviolet light source 2 is adjustable, and the emitted deep ultraviolet light has a wavelength of 200nm-400nm.

[0029] The special camera 3 includes a camera sensor, and the front end of the camera sensor is provided with an optical filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com