Low temperature-resistant high-rate AGM start-stop battery anode lead plaster and preparation method thereof

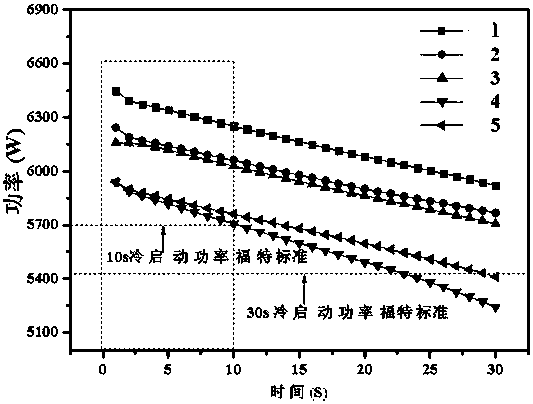

A battery negative electrode, high-rate technology, applied in battery electrodes, lead-acid batteries, circuits, etc., can solve problems such as difficulty in starting and stopping batteries, low-temperature high-rate starting performance needs to be improved, etc. performance, the effect of improving low temperature starting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 83.5kg of lead powder (containing 75% by mass of PbO) into the paste mixing machine. Add 0.08Kg of short fibers, 0.25Kg of carbon material, 0.67Kg of barium sulfate, and 0.42Kg of composite additives into the lead powder, stir and mix evenly, then quickly add 7.58Kg of RO water into the paste mixing machine, and mix with the lead powder Carry out wet mixing evenly, and then pour in slowly with a density of 1.35g / cm 3 (25ºC) sulfuric acid solution 7.5Kg, vacuumize during the mixing process, control the temperature of the mixing paste at 60ºC, stir evenly, cool down to 40ºC, and get the low temperature resistant high rate AGM start-stop battery negative electrode lead paste when the paste is released.

Embodiment 2

[0037] Add 83.7kg of lead powder (containing 79% by mass of PbO) into the paste mixing machine. Add 0.08Kg of short fiber, 0.17Kg of carbon material, 0.67Kg of barium sulfate, and 0.46Kg of composite additives into the lead powder, stir and mix evenly, then quickly add 7.75Kg of RO water into the paste machine, and mix with the lead powder Carry out wet mixing evenly, and then pour in slowly with a density of 1.35g / cm 3 (25ºC) sulfuric acid solution 7.17Kg, vacuumize during the mixing process, control the temperature of the mixing paste at 60ºC, stir evenly, cool down to 40ºC, and get the low temperature resistant high rate AGM start-stop battery negative electrode lead paste.

Embodiment 3

[0039] Add 83kg of lead powder (containing 76% by mass of PbO) into the paste mixing machine. Add 0.05Kg of short fiber, 0.25Kg of carbon material, 0.69Kg of barium sulfate, and 0.65Kg of composite additives into the lead powder, stir and mix evenly, then quickly add 8.21Kg of RO water into the paste machine, and mix with the lead powder Carry out wet mixing evenly, and then pour in slowly with a density of 1.35g / cm 3 (25ºC) sulfuric acid solution 7.15Kg, vacuumize during the paste mixing process, control the temperature of the paste to 60ºC, stir evenly, cool down to 40ºC, and get the low temperature resistant high rate AGM start-stop battery negative electrode lead paste when the paste is released.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com