Radially-magnetized double-ring magnetic steel permanent magnet motor

A radial magnetization, permanent magnet motor technology, applied in the direction of magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of high magnetic performance requirements of magnetic steel, large motor operating current, low product qualification rate, etc., to improve the accuracy of the instrument , improve efficiency, and the effect of advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

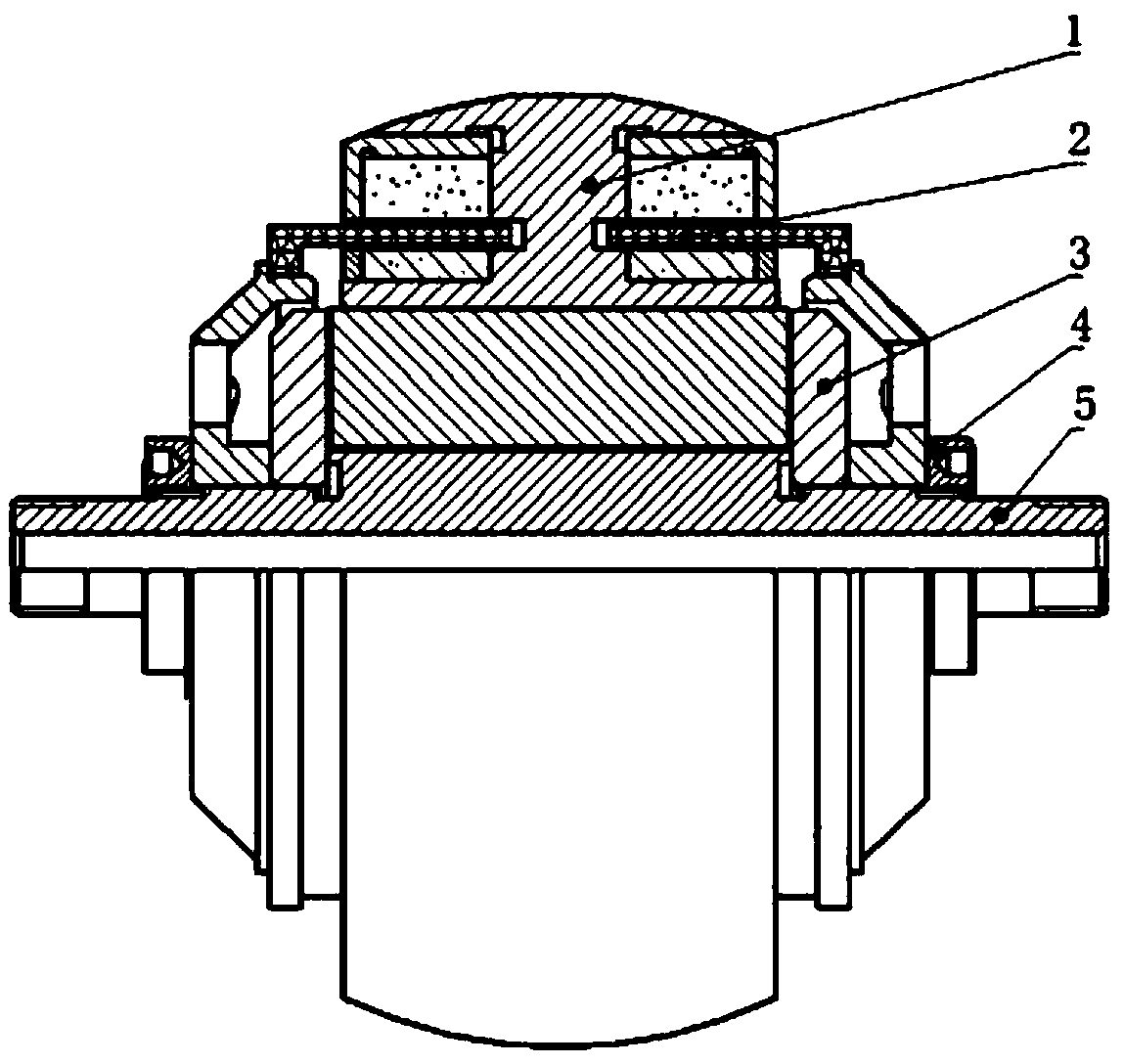

[0020] A radially magnetized double-ring magnetic steel permanent magnet motor adopts two inner and outer magnetic steel rings and a symmetrical double stator structure. The bearing is a through-hole dynamic pressure gas bearing, and the stator adopts a frameless structure. The motor includes a rotor 1, two stators 2, two thrust plates 3, two nuts 4 and a shaft 5.

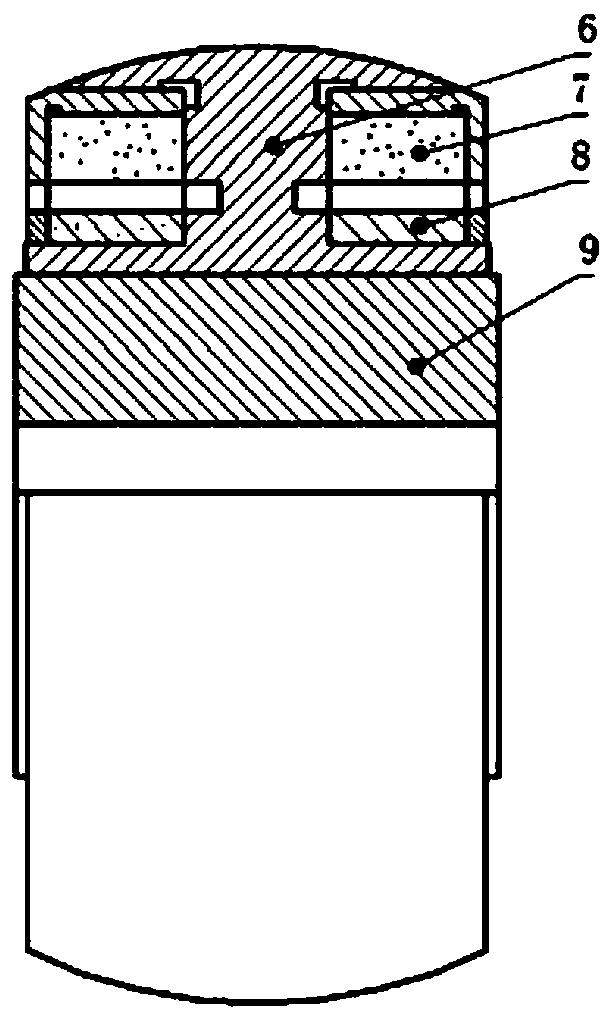

[0021] The moment of momentum required by the gyroscope is provided by the rotor, and the rotor (such as figure 2 Shown) is made up of a rotor ring 6, two outer magnetic steel rings 7, two inner magnetic steel rings 8 and a bearing ring 9. The inner surface of the outer magnetic steel ring is the working surface, and the outer surface of the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com