Method for extracting albumen powder by using broken rice

A technology of protein powder and broken rice, which is applied in the field of protein powder separation and extraction, can solve the problems of low protein content, lower protein extraction rate, and imperfect extraction method, and achieve the advantages of convenient operation, high protein content, and material saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

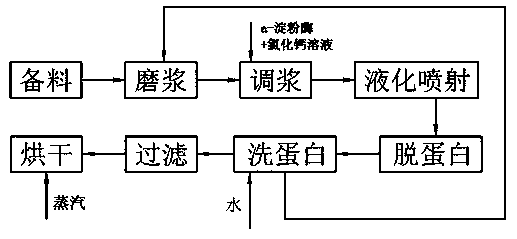

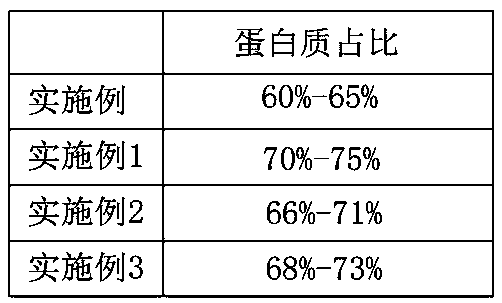

[0027] Example 1, please refer to the attached Figure 1-2 , utilize broken rice to carry out the method for the extraction of protein powder, it is characterized in that: comprise the steps of following order:

[0028] A: Material preparation: take an appropriate amount of broken rice to remove stones and impurities, then wash the broken rice after stone removal, and then add water for soaking;

[0029] B: Refining: filter the broken rice soaked in A in step A to obtain broken rice and add it to the rice mill, and add protein washing water for refining treatment;

[0030] C: Sizing: add 15U / g of a-amylase and 19Be' calcium chloride solution to the solution obtained after refining, adjust the pH value to 5.8-6.0h by adding water, and then use a mixer to uniformly stir;

[0031] D: liquefaction jet: inject the slurry obtained in step C into the jet liquefier and contact with the steam, control the discharge temperature to be 105~108 ℃, the feed liquid coming out from the jet l...

Embodiment 2

[0036] Example 2, please refer to the attached Figure 1-2 , utilize broken rice to carry out the method for the extraction of protein powder, it is characterized in that: comprise the steps of following order:

[0037] A: Material preparation: take an appropriate amount of broken rice to remove stones and impurities, then wash the broken rice after stone removal, and then add water for soaking;

[0038] B: Refining: filter the broken rice soaked in A in step A to obtain broken rice and add it to the rice mill, and add water for refining;

[0039] C: Sizing: add 15U / g of a-amylase and 19Be' calcium chloride solution to the solution obtained after refining, adjust the pH value to 5.8-6.0h by adding water, and then use a mixer to uniformly stir;

[0040] D: liquefaction injection: inject the slurry obtained in step C into the jet liquefier to contact with steam, control the discharge temperature to be 106 ° C, and the feed liquid from the jet liquefier enters the laminar flow t...

Embodiment 3

[0045] Example 3, please refer to the attached Figure 1-2 , utilize broken rice to carry out the method for the extraction of protein powder, it is characterized in that: comprise the steps of following order:

[0046] A: Material preparation: take an appropriate amount of broken rice to remove stones and impurities, then wash the broken rice after stone removal, and then add water for soaking;

[0047] B: Refining: filter the broken rice soaked in A in step A to obtain broken rice and add it to the rice mill, and add protein washing water for refining treatment;

[0048] C: Sizing: add 15U / g of a-amylase and 19Be' calcium chloride solution to the solution obtained after refining, adjust the pH value to 5.8-6.0h by adding water, and then use a mixer to uniformly stir;

[0049] D: liquefaction jet: inject the slurry obtained in step C into the jet liquefier and contact with the steam, control the discharge temperature to be 105~108 ℃, the feed liquid coming out from the jet l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com