Staggered-tooth molded high-gloss chamfer milling cutter

A high-gloss chamfering and milling cutter technology, applied in milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of easy generation of vibration lines, burrs, line lines, low processing efficiency, low production efficiency, etc., to prevent chipping. , The effect of improving production efficiency and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be clearly and completely described below.

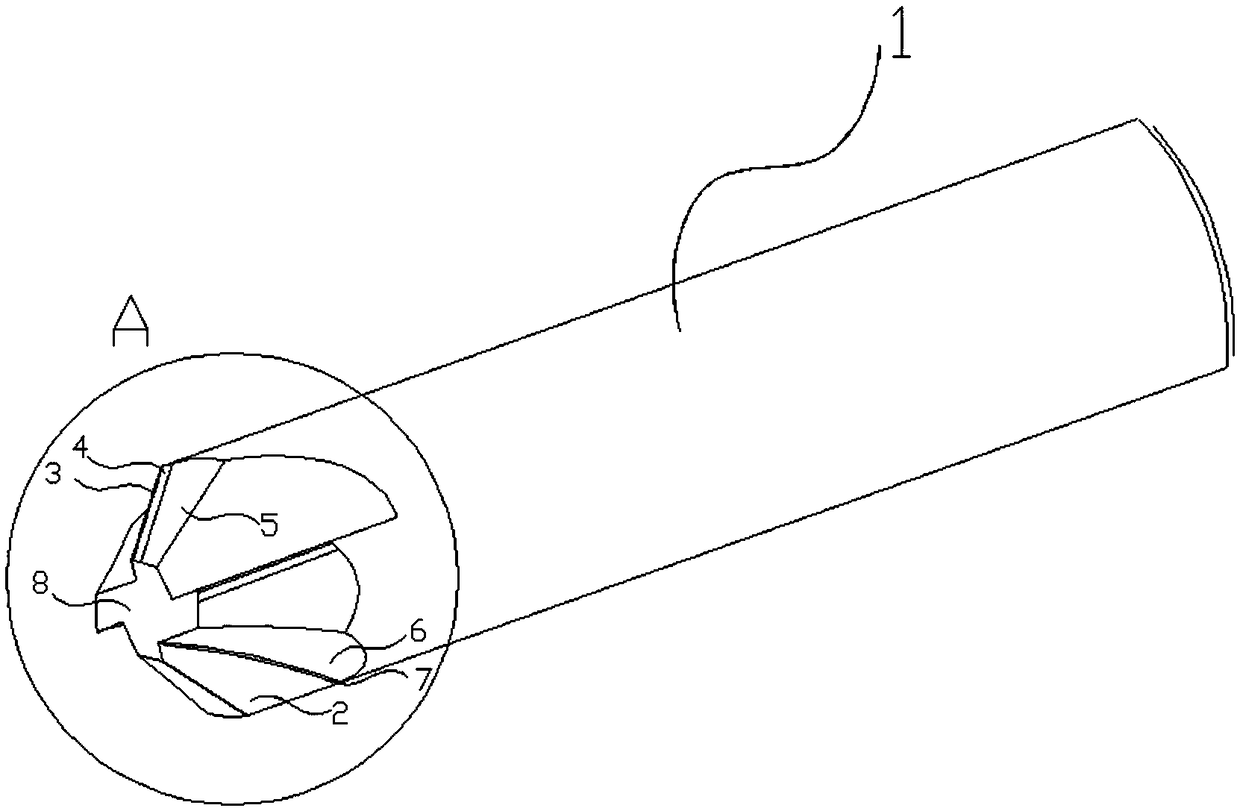

[0028] A high-gloss chamfer milling cutter with staggered teeth, such as figure 1 Shown, including knife handle, knife head;

[0029] The knife handle 1 and the knife head are integrally formed, and the knife head includes a first knife edge, a second knife edge, a third knife edge, and a fourth knife edge, the first knife edge, the second knife edge, the third knife edge, and the fourth knife edge in sequence Clockwise opened at the end of the knife handle;

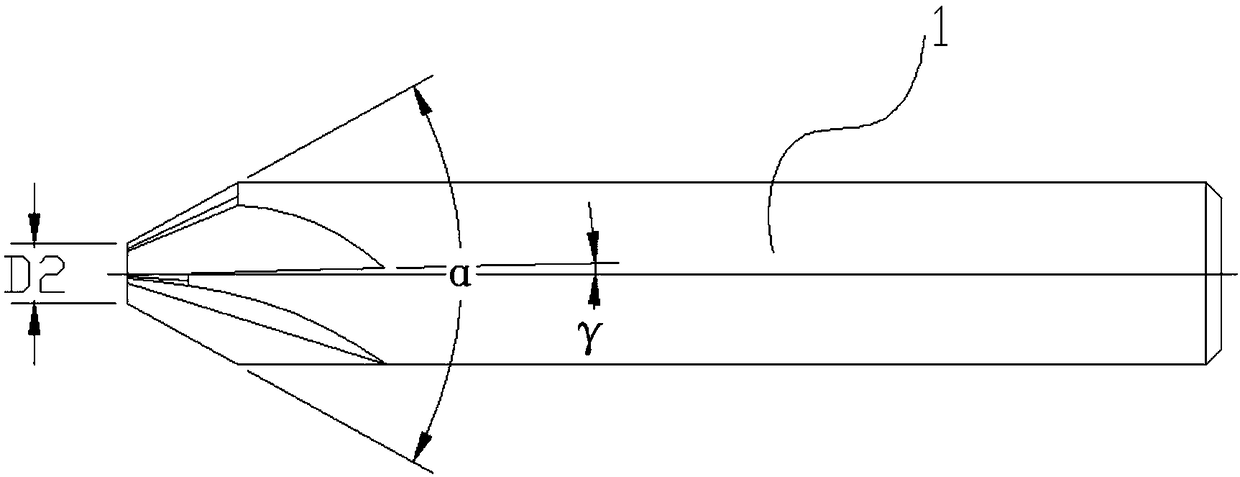

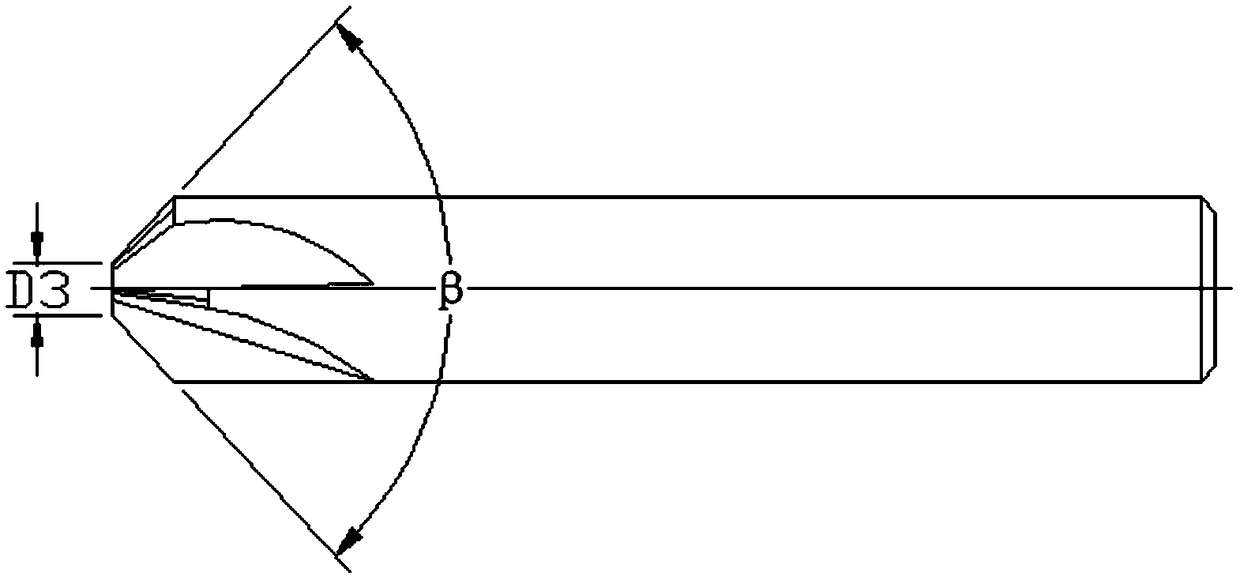

[0030] The first blade, the second blade, the third blade, and the fourth blade are inclined outwardly and share a front end surface 8, such as figure 1 As shown, the front end surface 8 is a flat surface, and the first blade and the third blade, the second blade and the fourth blade are symmetrical about the axis end point of the handle, and the front ends of the first blade and the third blade have diameters D2 is greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com