Rope-laying mechanical arm used for straw plate production system

A production system and robotic arm technology, which is applied to manipulators, program-controlled manipulators, chucks, etc., can solve problems such as affecting the efficiency of production lines and reducing product economic benefits, and achieve the effects of simple structure, improved economic benefits, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

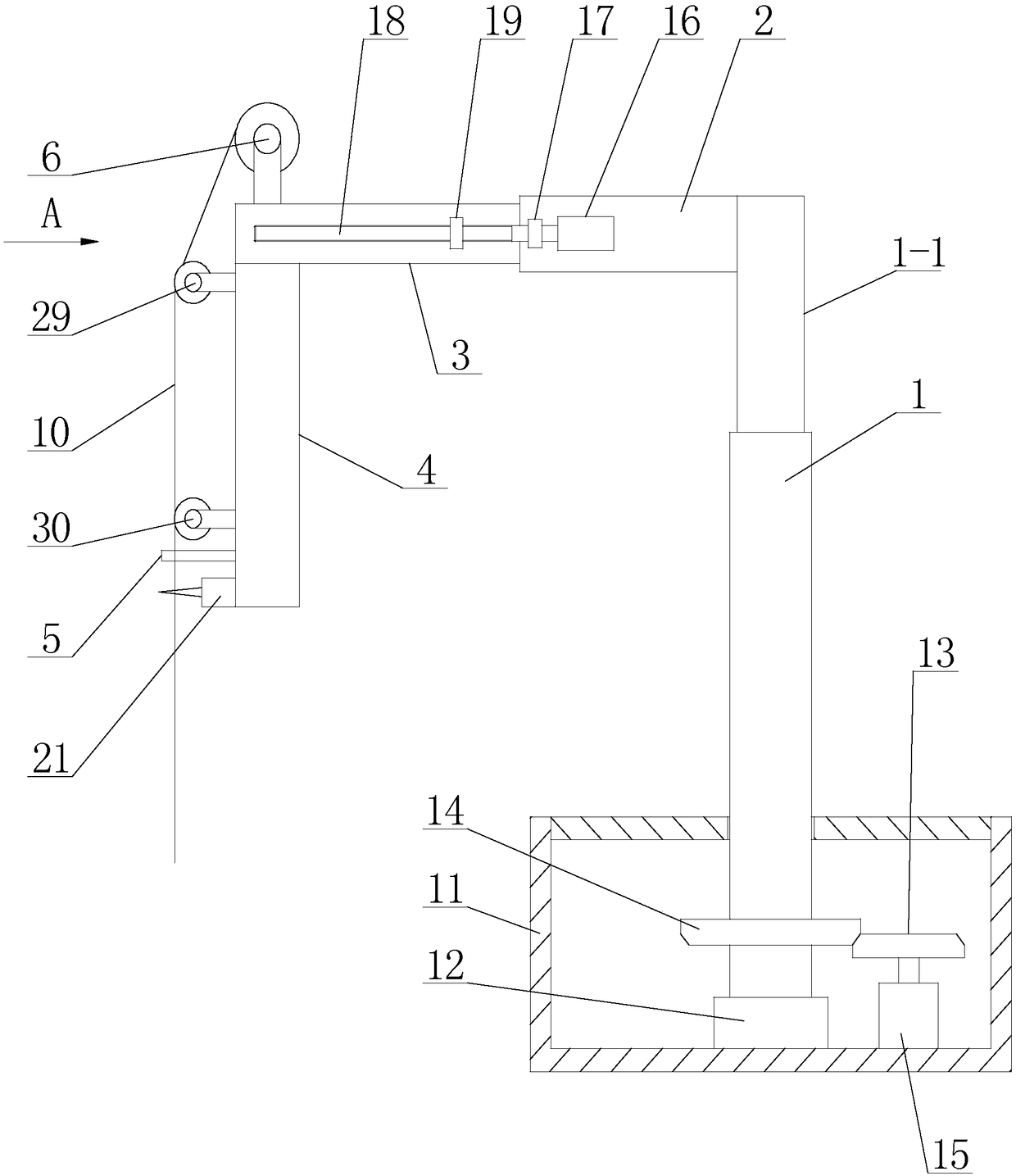

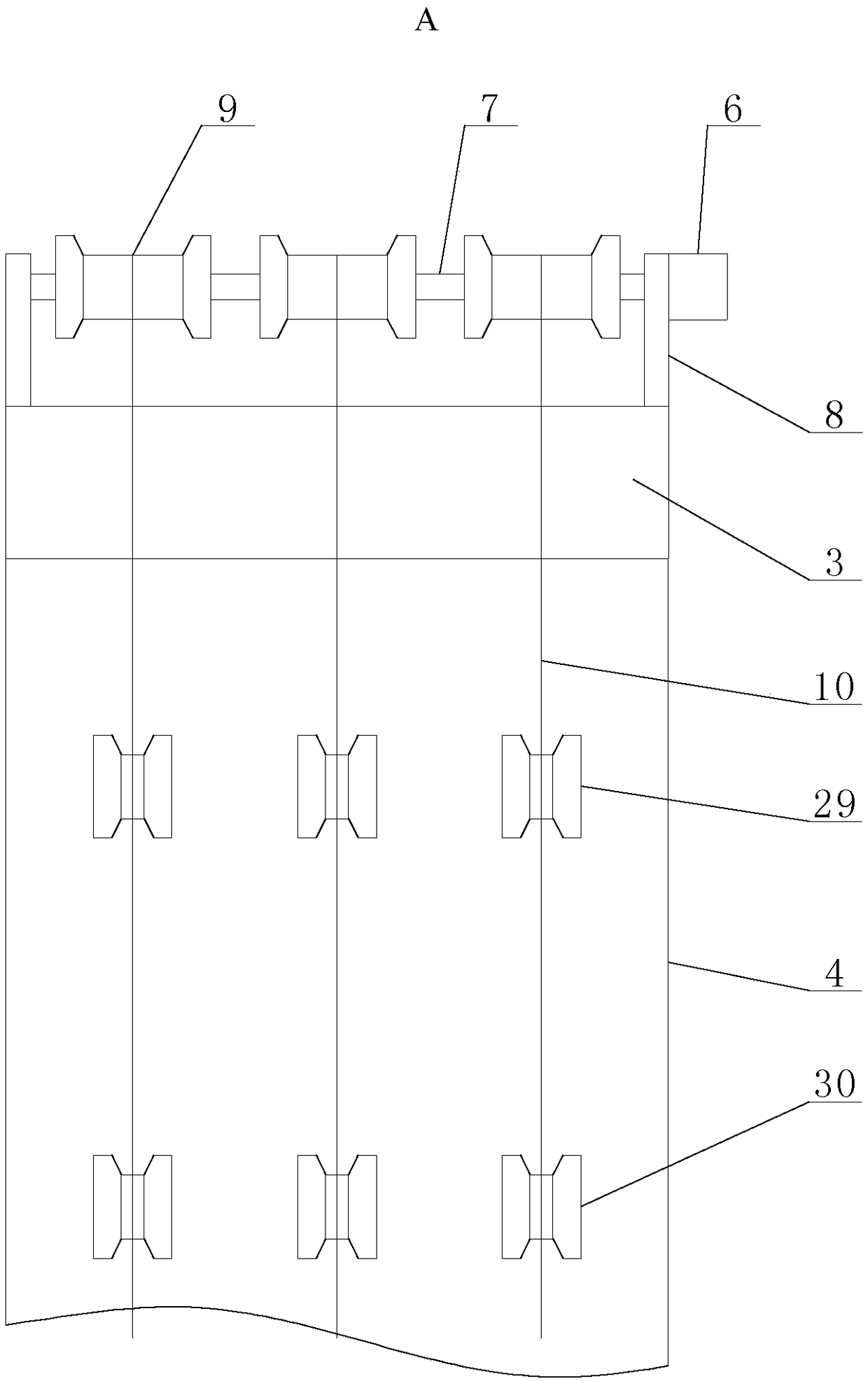

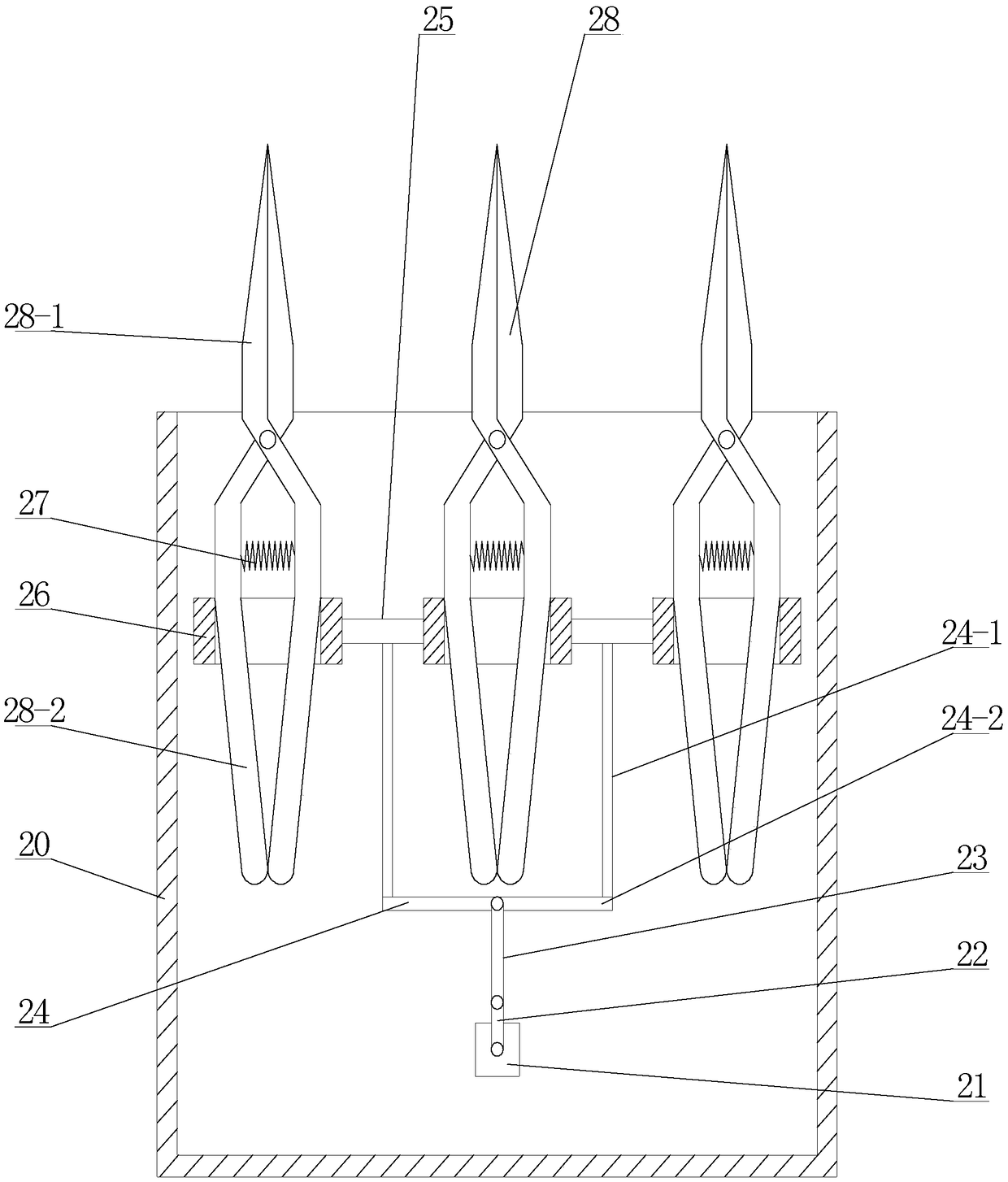

[0013] Specific implementation mode one: combine Figure 1 to Figure 3 To illustrate this embodiment, a line-laying robotic arm for a straw slab production system described in this embodiment includes a rotating base assembly, a lifting electric hydraulic cylinder 1, a fixed beam 2, a telescopic beam 3, a vertical boom 4, a translation drive mechanism, Counter 5, wire rope retractable motor 6, reel shaft 7, reel support 8, wire rope cutting mechanism and three reels 9, the lower end of lifting electric hydraulic cylinder 1 is installed on the rotating base assembly, and the fixed beam 2. Set horizontally. One end of the fixed beam 2 is fixedly connected to the upper end of the piston rod 1-1 of the lifting electric hydraulic cylinder 1. The telescopic beam 3 is set horizontally. One end of the telescopic beam 3 is installed in the other end of the fixed beam 3. The translation drive mechanism is installed on the fixed beam 2, the side wall of the telescopic beam 3 is connected...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination Figure 1 to Figure 3 To illustrate this embodiment, the rotating base assembly of a line-laying robotic arm for a straw slab production system described in this embodiment includes a housing 11, a bearing seat 12, a driving gear 13, a driven gear 14, and a rotating drive motor 15, and the bearing seat 12 is fixedly installed on the bottom of the housing 11, the bottom of the lifting electric hydraulic cylinder 1 is connected to the bearing seat 12 in rotation, the rotating drive motor 15 is fixedly installed in the housing 11, and the driving gear 13 is set on the rotating shaft of the rotating driving motor 15 , the driven gear 14 is sleeved on the bottom of the lifting electric hydraulic cylinder 1, and the driving gear 13 meshes with the driven gear 14. The rotation driving motor 15 drives the driving gear 13 to rotate, and the driving gear 13 drives the bottom of the lifting electric hydraulic cylinder 1 to rotate throu...

specific Embodiment approach 3

[0015] Specific implementation mode three: combination Figure 1 to Figure 3 Describe this embodiment, the translation drive mechanism of a line-laying robotic arm for a straw slab production system described in this embodiment includes a translation drive motor 16, a reducer 17, a screw 18 and a nut 19, and the translation drive motor 16 is fixedly installed on a fixed beam On the side of 2, screw rod 18 is arranged horizontally, and one end of screw rod 18 is connected with the rotating shaft of translation drive motor 16 through reducer 17, and nut 19 is fixedly installed on the side of telescopic beam 3, and nut 19 is sleeved on the screw rod 18. The translation drive motor 16 drives the screw rod 18 to rotate forward or reverse through the reducer 17, and the screw rod 18 and the nut 19 cooperate to realize the linear reciprocating telescopic movement of the telescopic beam 3 along the fixed beam 2 . Other components and connections are the same as those in the first embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com