Sliding plate type internal mold plate of thin-wall hollow pier with variable section

A thin-walled hollow pier and variable cross-section technology, applied in the direction of formwork/template/work frame, erection/assembly of bridges, bridges, etc. The effect of engineering quality and safety, high market promotion value, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

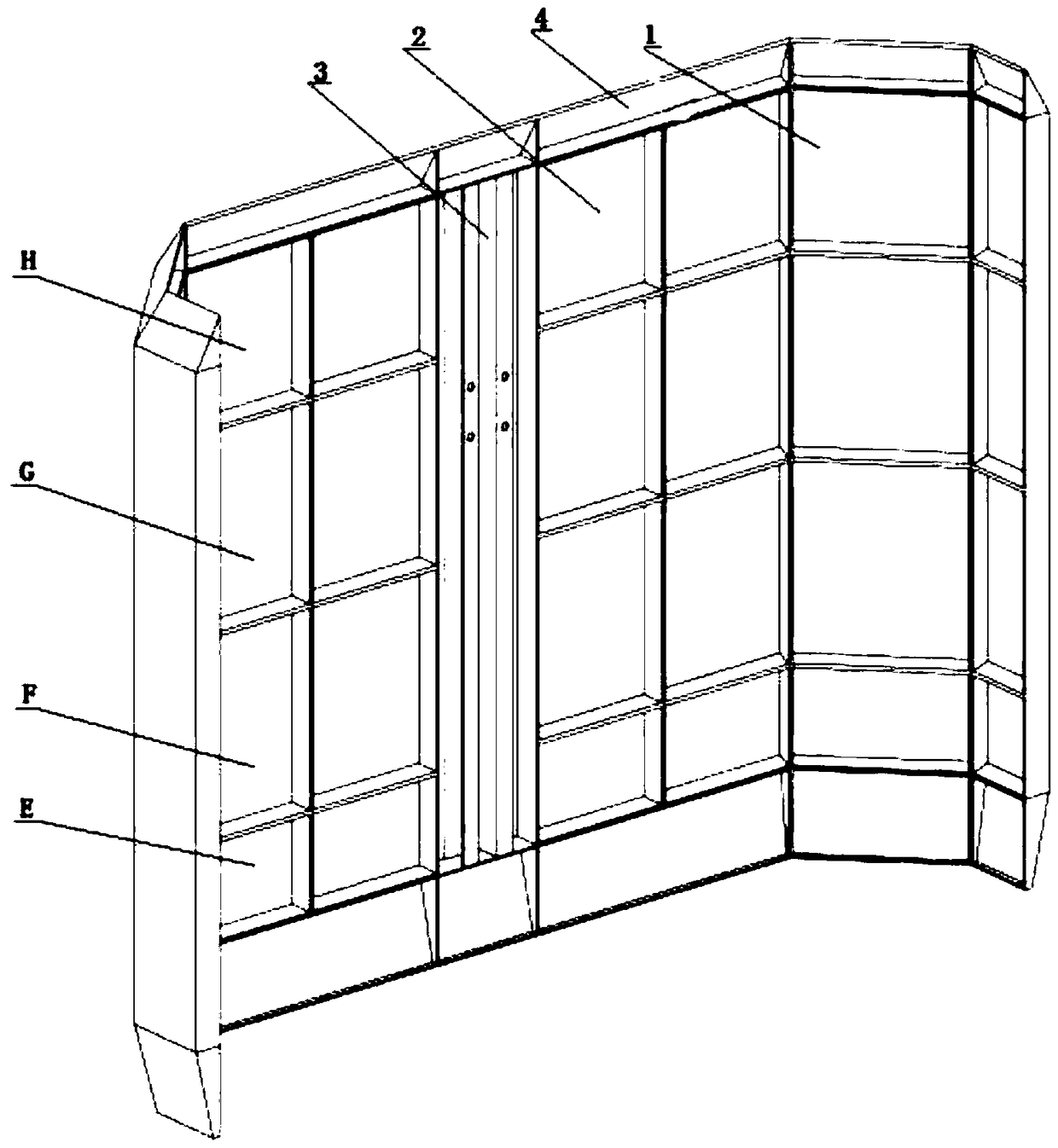

[0038] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

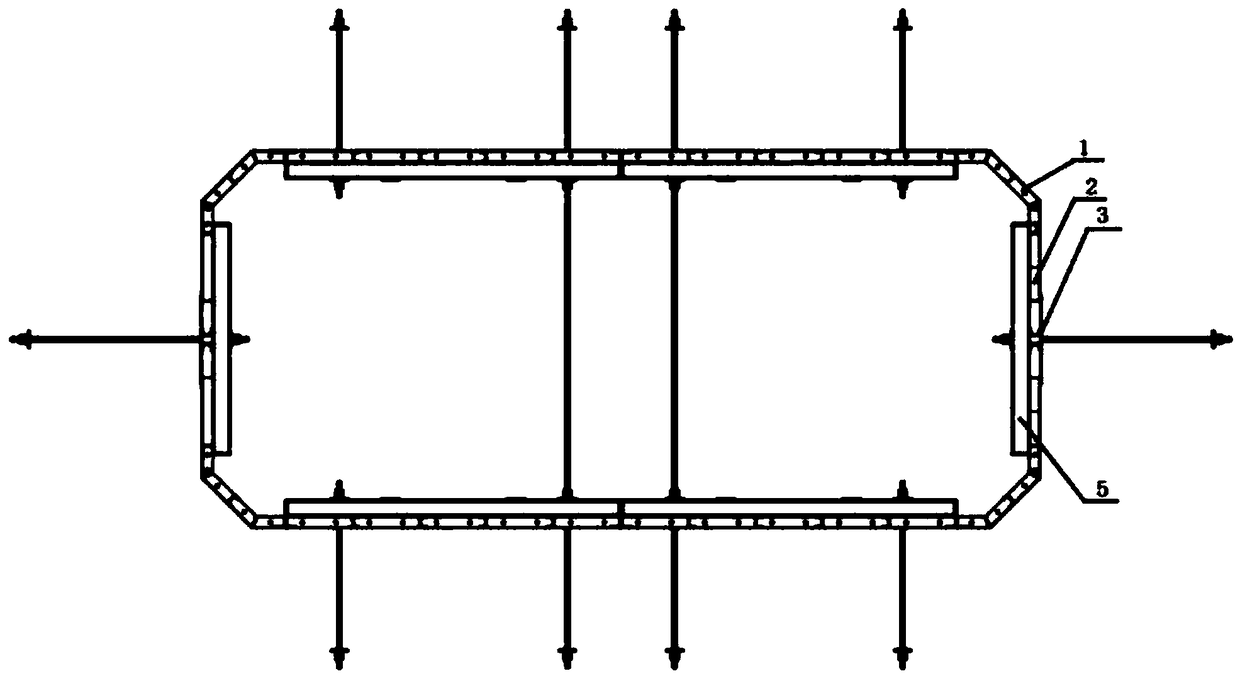

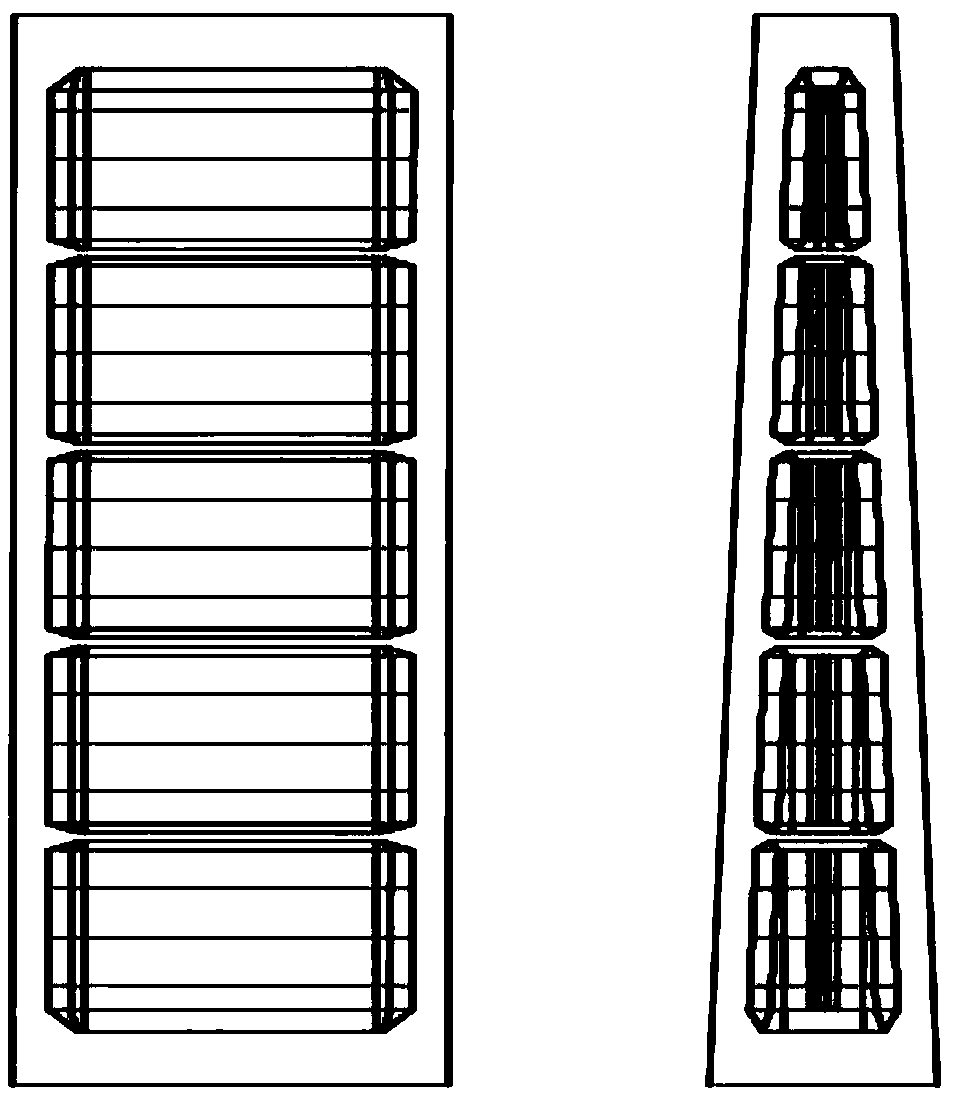

[0039] The installation method of the sliding plate type inner formwork of the variable cross-section thin-walled hollow pier of the present invention includes the installation of the equal cross-section part and the installation of the variable cross-section part. The inner formwork is composed of two constant cross-section facades and two variable cross-section facades. Follow the steps below to install:

[0040] h) The installation of the constant section part and the variable section part are divided according to the combination diagram of the equal section and variable section of the formwork of the full height of the empty box;

[0041] i) Combined with the requirement of secondary pouring and pouring position of pier column empty box concrete, equal cross-section formwork is divided into secondary installation;

[0042] j) Combining wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com