Formant-Free Isolation Buffer

A shock absorber and non-resonance technology, which is applied in the direction of shock absorber, liquid shock absorber, shock absorber-spring combination, etc., can solve the vibration isolation buffer that is not at the midpoint of the spring piece, the friction force is uncontrollable, and there is no resonance peak Stuck and other problems, to achieve the effect of reducing the frequency of use, prolonging the life, and good vibration isolation frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

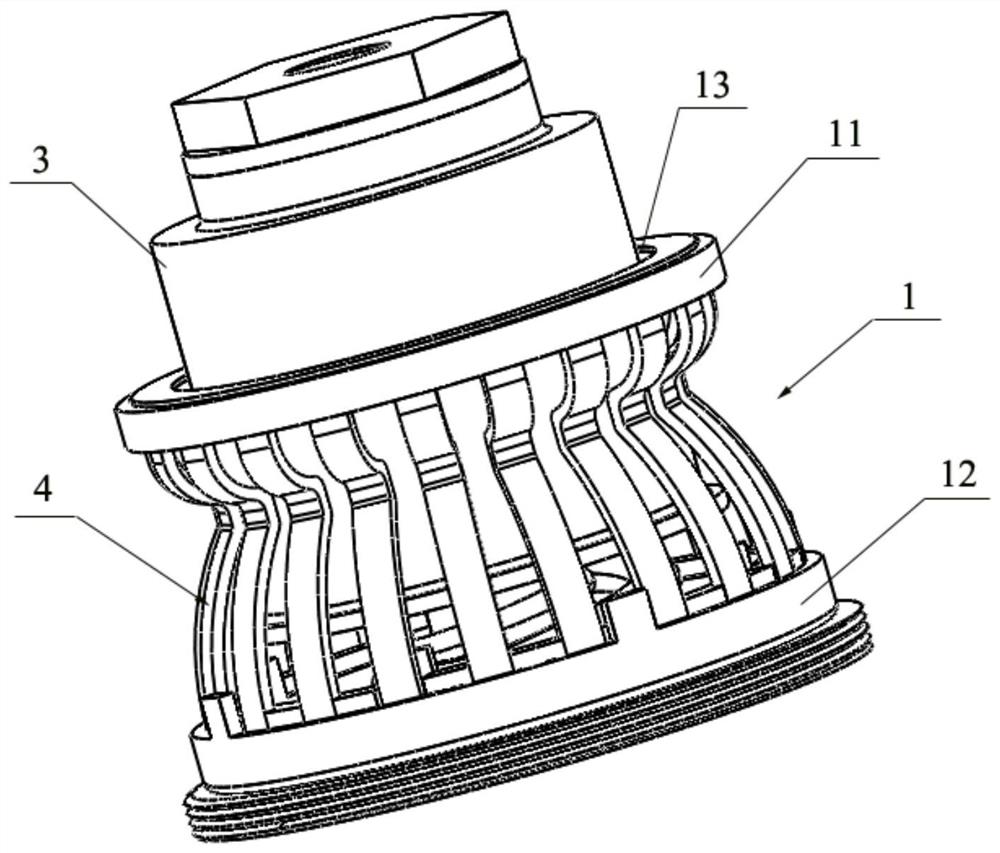

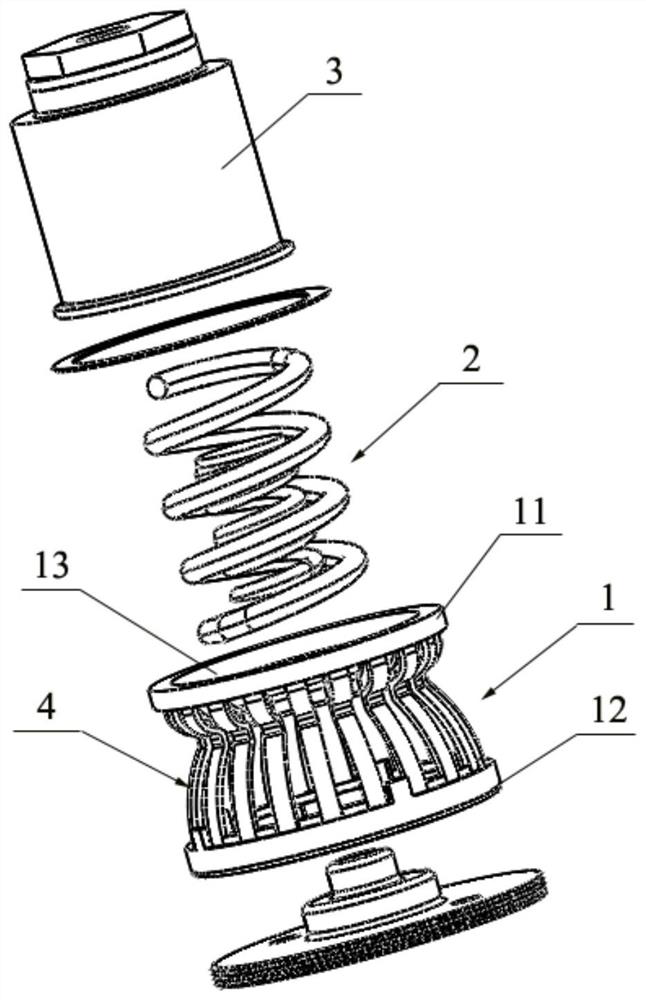

[0027] see Figure 2 to Figure 4 As shown, the embodiment of the present invention provides a vibration isolation buffer without resonance peak, which includes a connection mechanism 1 , a spring assembly 2 , a piston 3 and a damping assembly 4 .

[0028] Wherein, the connection mechanism 1 includes an upper cover plate 11 and an installation base 12 arranged at intervals, and the upper cover plate 11 is provided with a through hole 13 .

[0029] The spring assembly 2 is fixed on the installation base 12 .

[0030] One end of the piston 3 abuts against the spring assembly 2 , and the other end passes through the through hole 13 .

[0031] The damping assembly 4 includes a plurality of friction plates 41 arranged around the piston 3, each of the friction plates 41 includes a first arc segment 42, a second arc segment 43 and a transition segme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com