Vertical type air purifier with noise-reducing structure

An air purifier and vertical technology, which is applied in the field of vertical air purifiers, can solve the problems of hindering the air inlet, the size of the air outlet cannot be changed accordingly, and affecting the structural strength of the shell, so as to achieve the effect of improving the use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

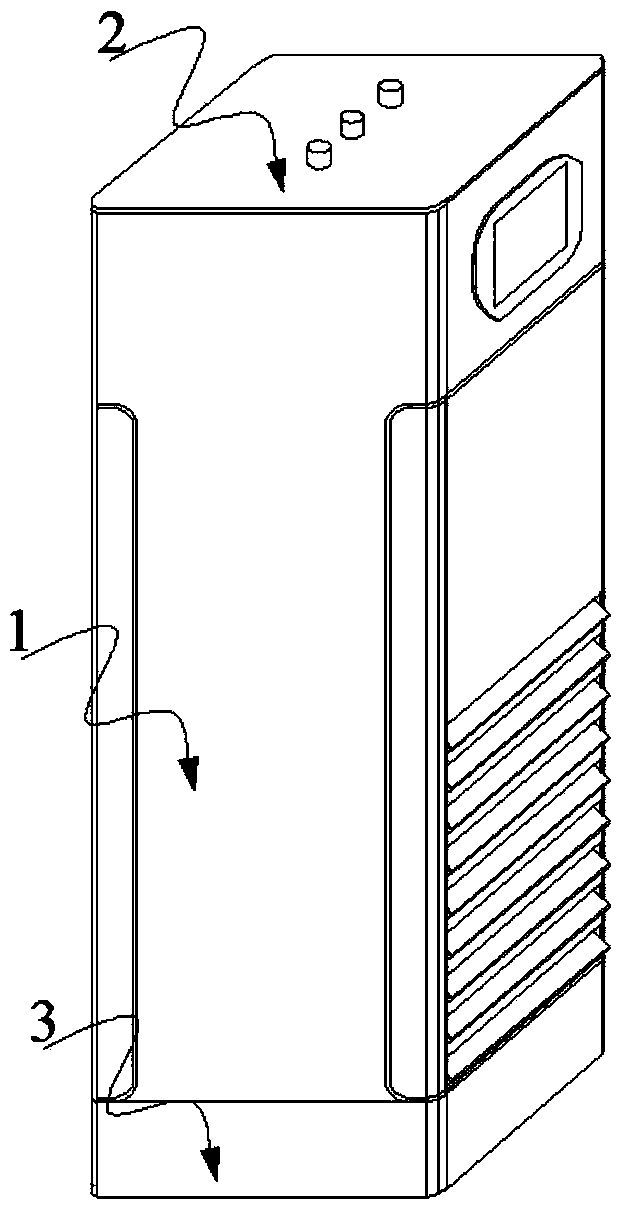

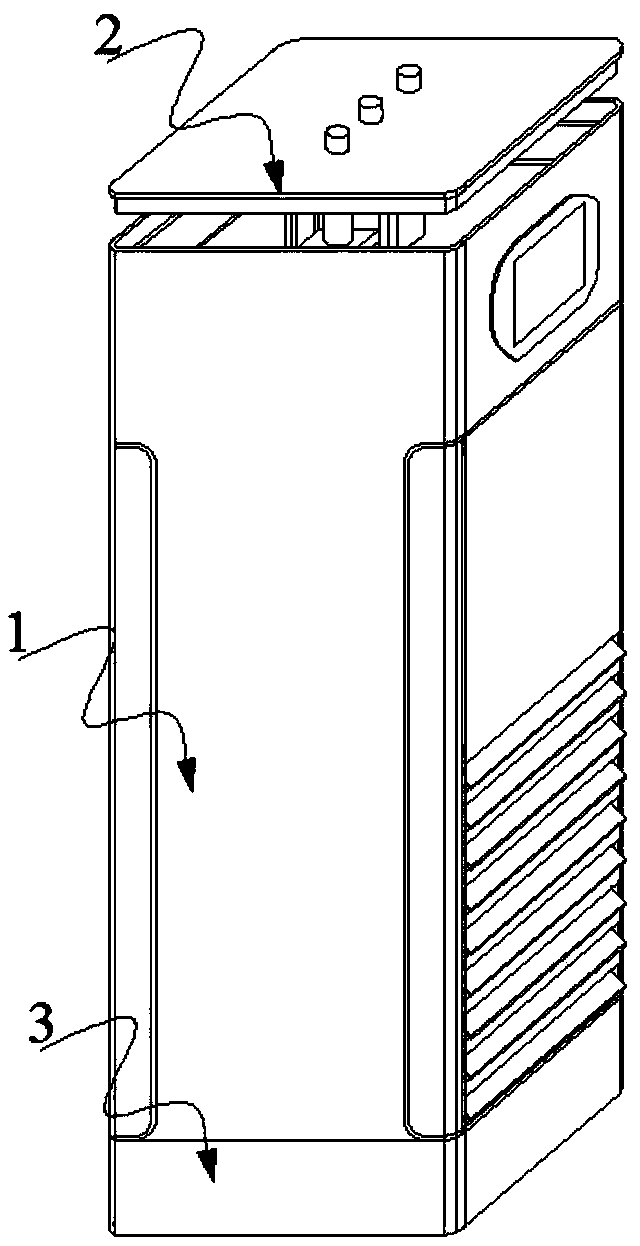

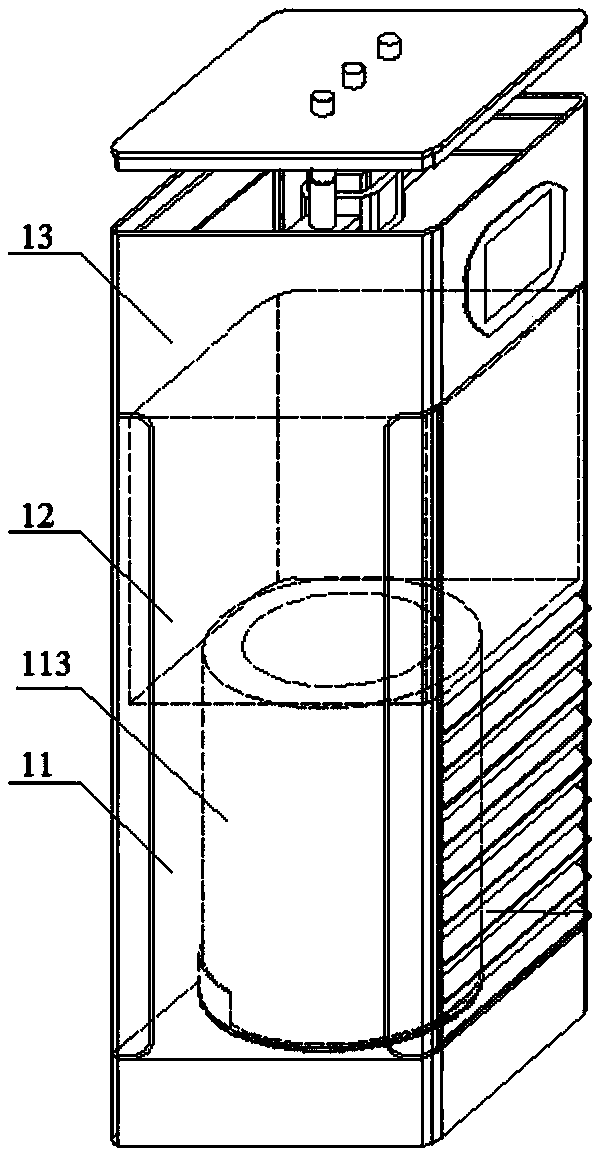

[0052] see figure 1 In this embodiment, a vertical air cleaner with a noise reduction structure is provided, including a housing 1 and an air outlet cover 2 that is movable to cover the top opening of the housing 1. The air outlet cover 2 can be opened from the top Lift up and fall back to the original position. When the air outlet cover 2 rises upward, it forms an air outlet with the top opening of the housing 1. The air outlet becomes larger or smaller as the air outlet cover 2 rises; see image 3 , The casing 1 includes an air inlet portion 11 , a fan portion 12 and an air outlet portion 13 arranged from bottom to top.

[0053] When the air purifier of this embodiment is working, the air purification process is as follows: the fan of the fan part 12 operates to make the air inlet part 11 enter the air, and the indoor air enters the housing 1 from the air inlet part 11, and passes through the filter mechanism 113 in the housing 1 After filtration and purification, it is ext...

Embodiment 2

[0067] see Figure 11 , 12 and Figure 13 , on the basis of Embodiment 1, the difference of Embodiment 2 is that the way to realize the rotary drive mechanism is: a turntable 34 is arranged in the base 3, and the turntable 34 is coaxially connected with the chassis 1141 through another rotating shaft, and the turntable 34 The side wall is provided with a plurality of rotation aids 341 along the axial direction, and a gap 33 is defined in the side wall of the base 3 . The gap 33 is provided with a gap cover plate 331 which can be opened or covered with the gap 33 .

[0068] In this embodiment, the method of driving the filter mechanism 113 to rotate is changed to manual drive. After the filter mechanism 113 has been used for a period of time, the user can open the notch cover 331 and rotate the turntable 34 through the rotation auxiliary part 341. The turntable 34 rotates to drive the chassis 1141 and The filter mechanism 113 rotates together, so that the filter mechanism 113...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com