Detection method for surface shape of multiple surfaces of transmission component

A technology of surface shape detection and transmission elements, applied in the field of measurement, can solve the problems of high precision and versatility in multi-surface detection of transmission elements, achieve high precision and large dynamic range, reduce cost requirements and cumbersomeness, and be universal good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

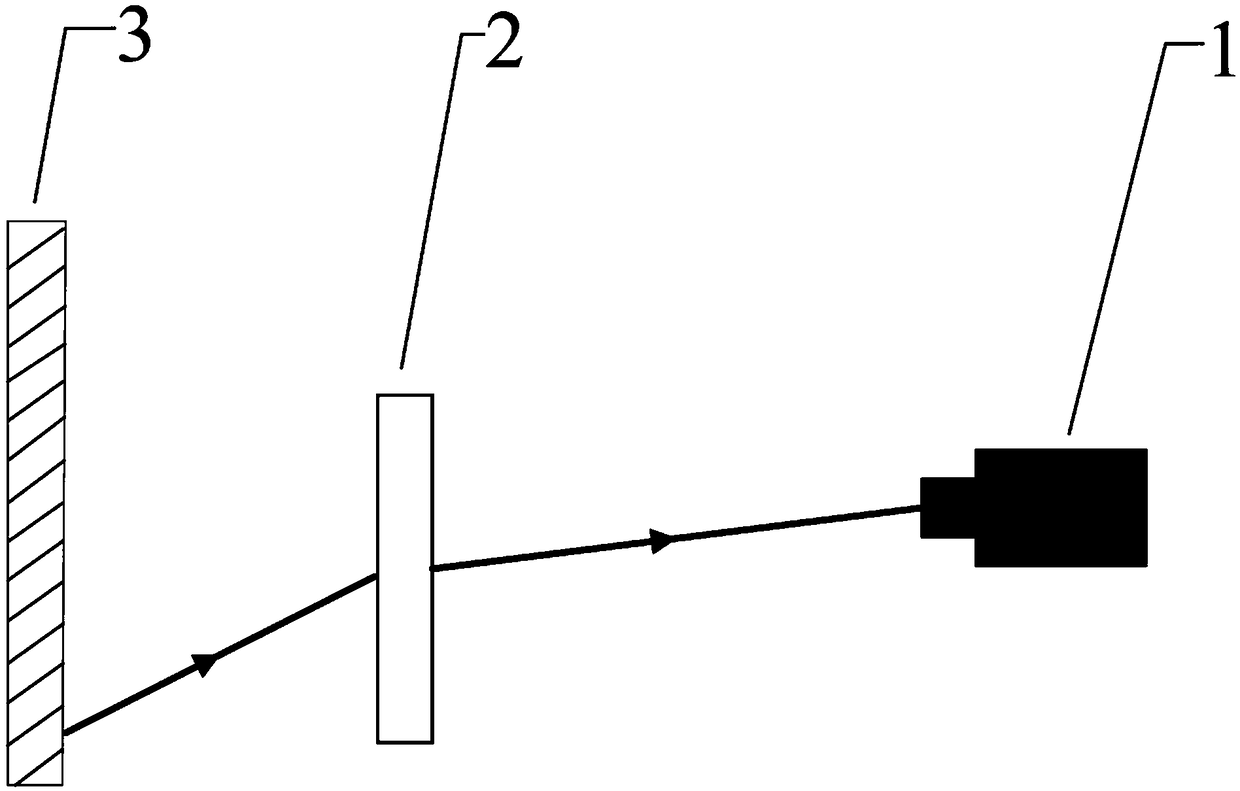

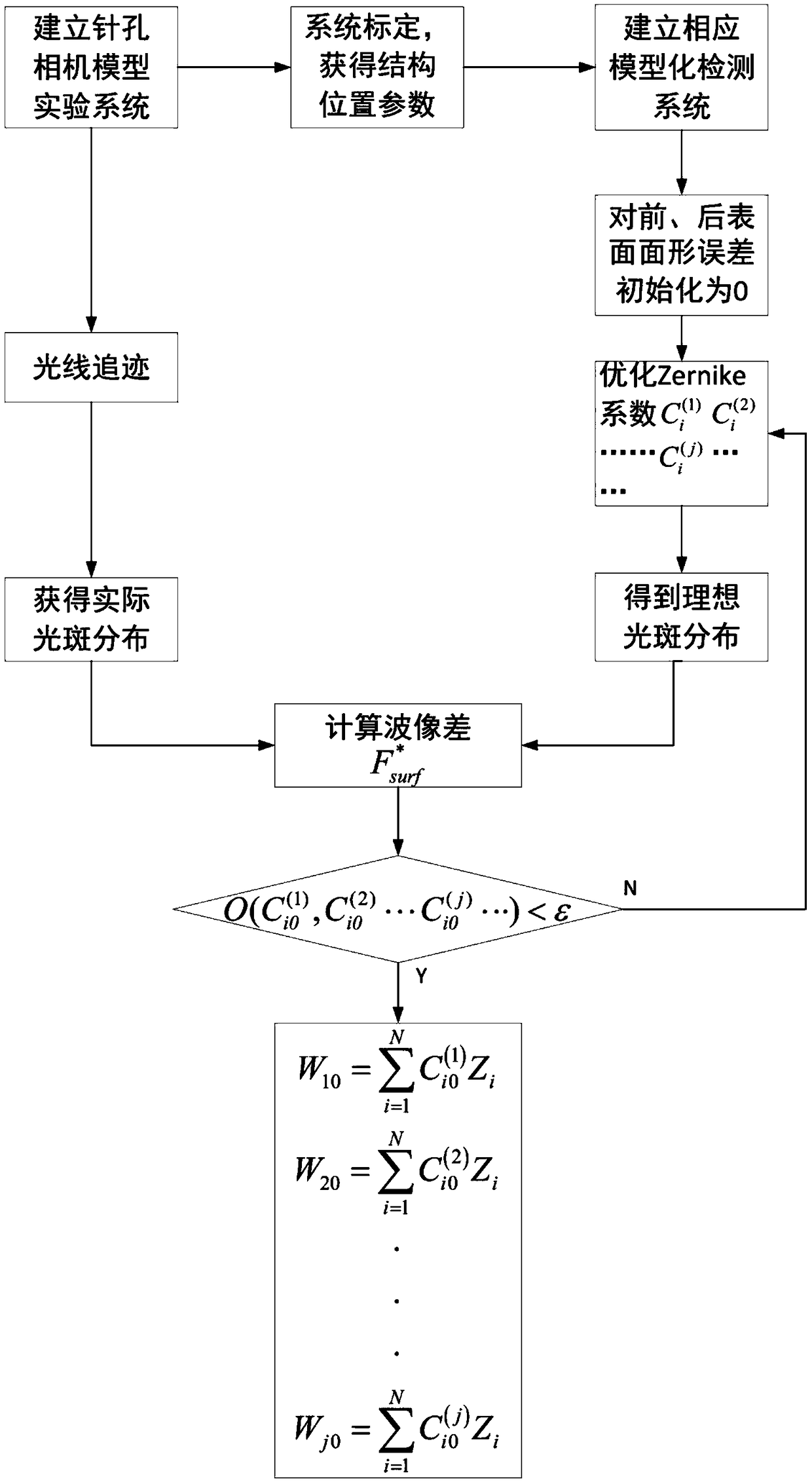

[0019] like figure 1 As shown, a multi-surface shape detection method of a transmission component includes a camera 1, a component to be measured 2, a projection screen 3 and a computer. The component to be tested 2 is a workpiece through which light can transmit. The device under test 2 is placed between the projection screen 3 and the camera 1 . Adjust to make the lens of the camera 1 coincide with the optical axis of the component under test 2 and be perpendicular to the screen of the projection screen 3 . The front end of camera 1 has a small filter hole to overcome aperture imaging aberration. The projection screen 3 displays a group of sinusoidal fringe patterns with modulated light intensity in the horizontal and vertical directions. The sinusoidal fringes pass through the component under test 2, and the camera 1 can obtain a complete image of the component under test 2, and collect the deformed fringes after imaging. The camera 1 and the projection screen 3 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com