BGA (Ball Grid Array) test socket adopting flexible connection

A test socket and flexible connection technology, which is applied in the field of BGA test sockets with flexible connections, can solve problems such as BGA ball damage, achieve the effect of reducing damage and realizing flexible connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

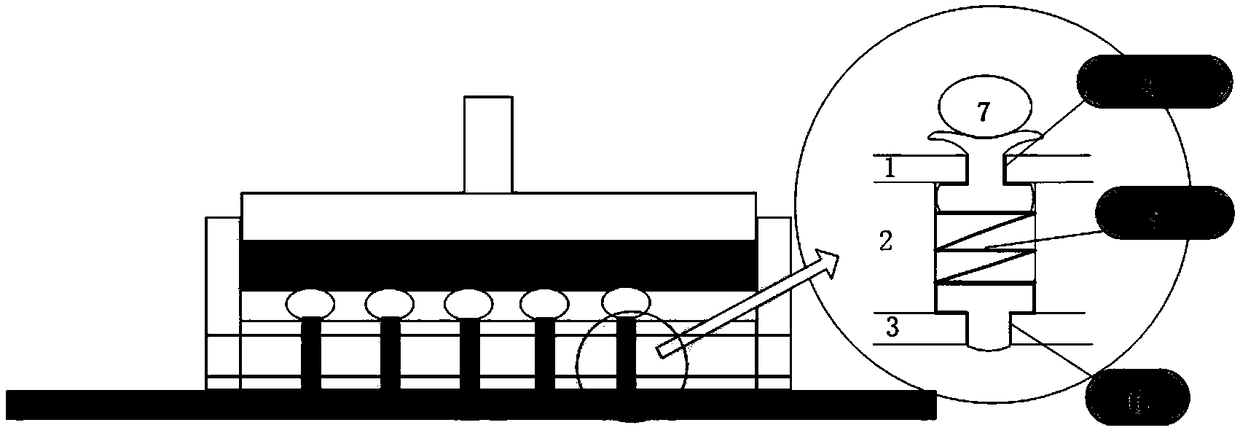

[0013] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

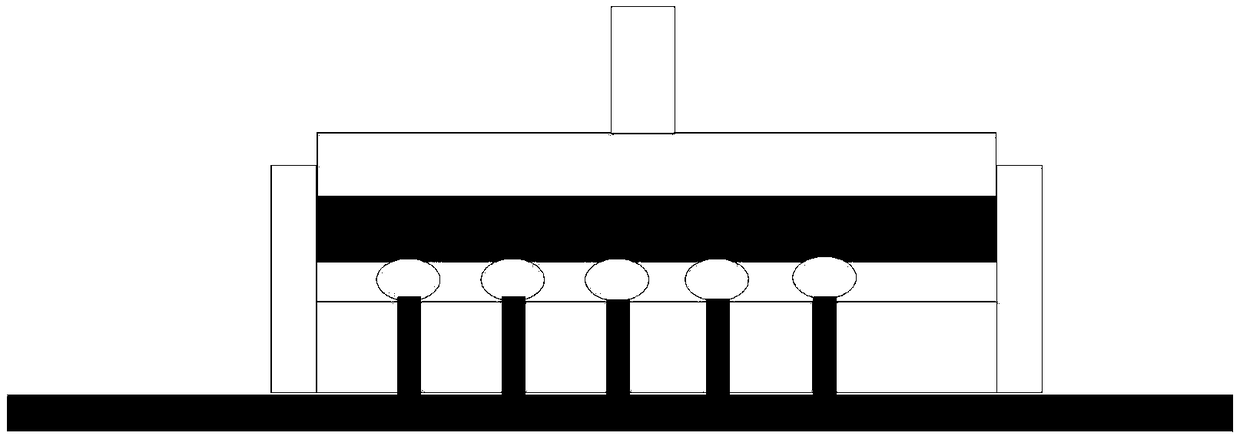

[0014] This embodiment proposes a flexible connection BGA test socket, its structure is as follows figure 2 shown. The BGA test socket includes a first socket layer 1 , a second socket layer 2 , a third socket layer 3 , conductive silicone rubber 4 , conductive springs 5 , metal pillars 6 and BGA balls 7 . Wherein, the first socket layer 1, the second socket layer 2, and the third socket layer 3 are stacked together from top to bottom, and pressed together by bolts around them to form a composite socket layer. Through holes are formed in the composite socket layer, wherein the size of the second through hole in the second socket layer 2 is larger than the first through hole in the first socket layer 1 and the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com