Tablet printing apparatus and tablet printing method

A printing device and printing method technology, applied in the directions of printing devices, printing, and devices that make medicines into special physical or ingesting forms, can solve problems such as poor printing, cracks or gaps, and improve recycling efficiency, reliability and safety. The effect of good product recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

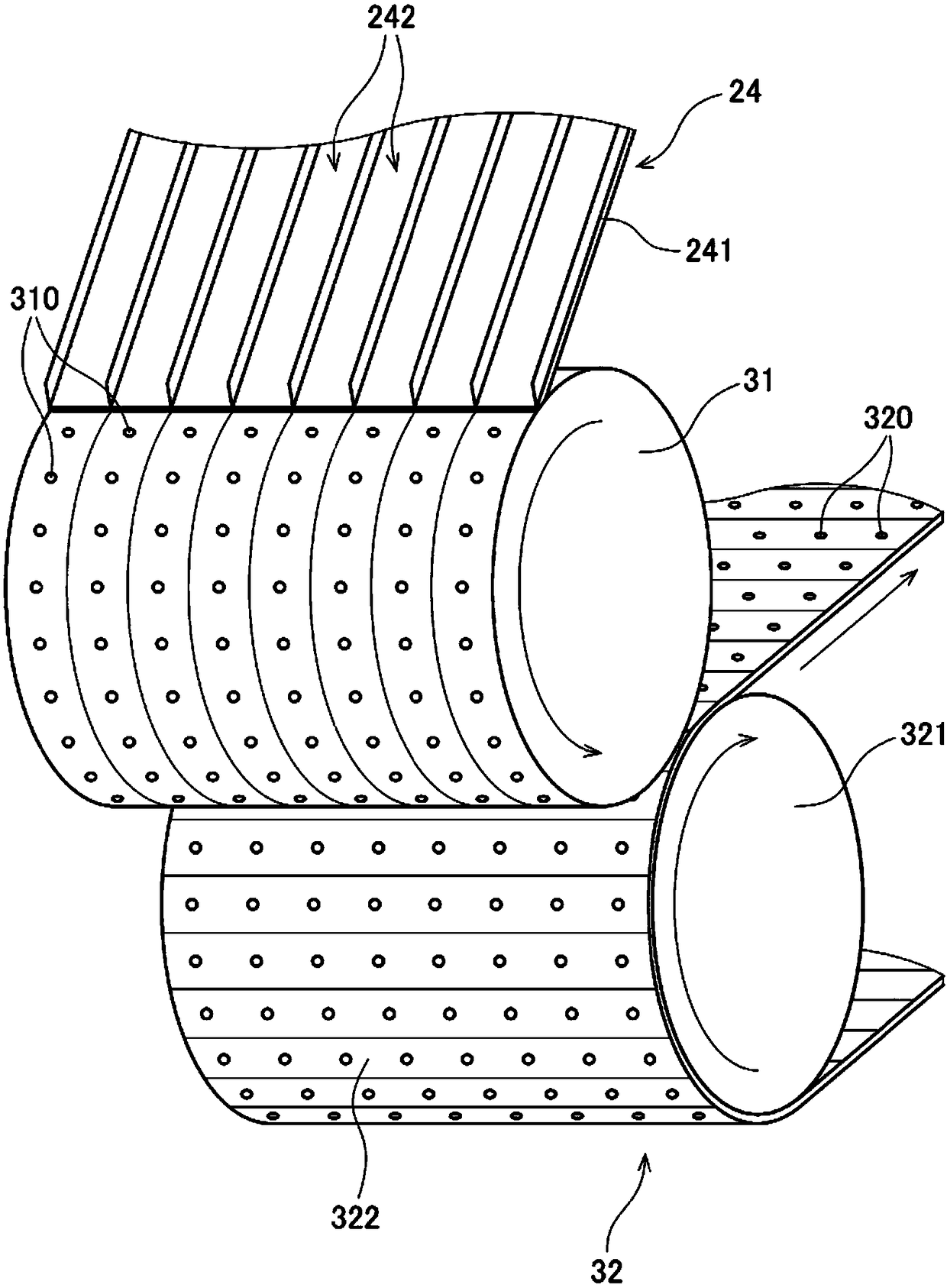

[0040] 1-1. Structure of tablet printing device

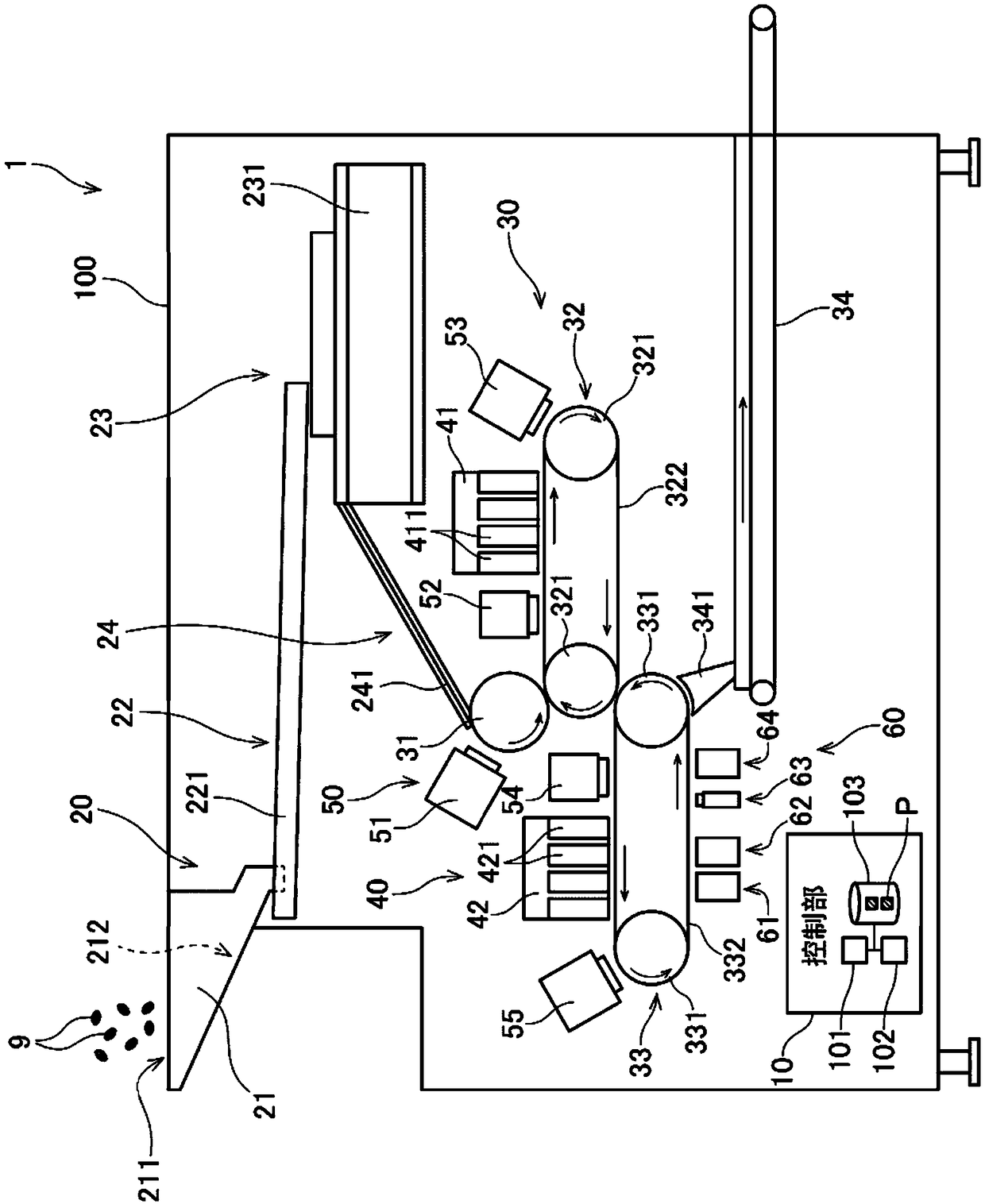

[0041] figure 1 It is a diagram showing the configuration of the tablet printing apparatus 1 according to the first embodiment of the present invention. The tablet printing device 1 is a device that prints images such as a product name, a product number, a company name, and a logo on the surface of each tablet 9 while conveying a plurality of tablets 9 that are medicines.

[0042] Such as figure 1As shown, the tablet printing apparatus 1 of this embodiment includes a supply mechanism 20 , a conveyance mechanism 30 , a printing unit 40 , an inspection mechanism 50 , a collection unit 60 , and a control unit 10 .

[0043] The supply mechanism 20 has a hopper 21 , a straight feeder 22 , a rotary feeder 23 , and an inclined feeder 24 . The supply mechanism 20 is a mechanism for transferring the tablets 9 thrown into the device to the transport mechanism 30 .

[0044] The hopper 21 is an input unit for taking many tablets 9 into...

no. 2 approach

[0121] Next, the flow of the printing process using the tablet printing apparatus 1 of the second embodiment will be described. The tablet printing device 1 of the second embodiment has the same device configuration as the tablet printing device 1 of the first embodiment. Figure 8 It is a flowchart showing the flow of the printing process of the tablet printing apparatus 1 of the second embodiment.

[0122]In the printing process of the second embodiment, the visual inspection of the second surface of the tablet 9 (step S201), the visual inspection of the first surface (step S202), the printing process on the first surface (step S203), Printing inspection on the first side (step S204), appearance inspection on the second side (step S205), printing process on the second side (step S206), printing inspection on the second side (step S207), collection of defective printing (step S208) and recovery of defective products (step S209).

[0123] Since steps S201 to S209 of the prin...

no. 3 approach

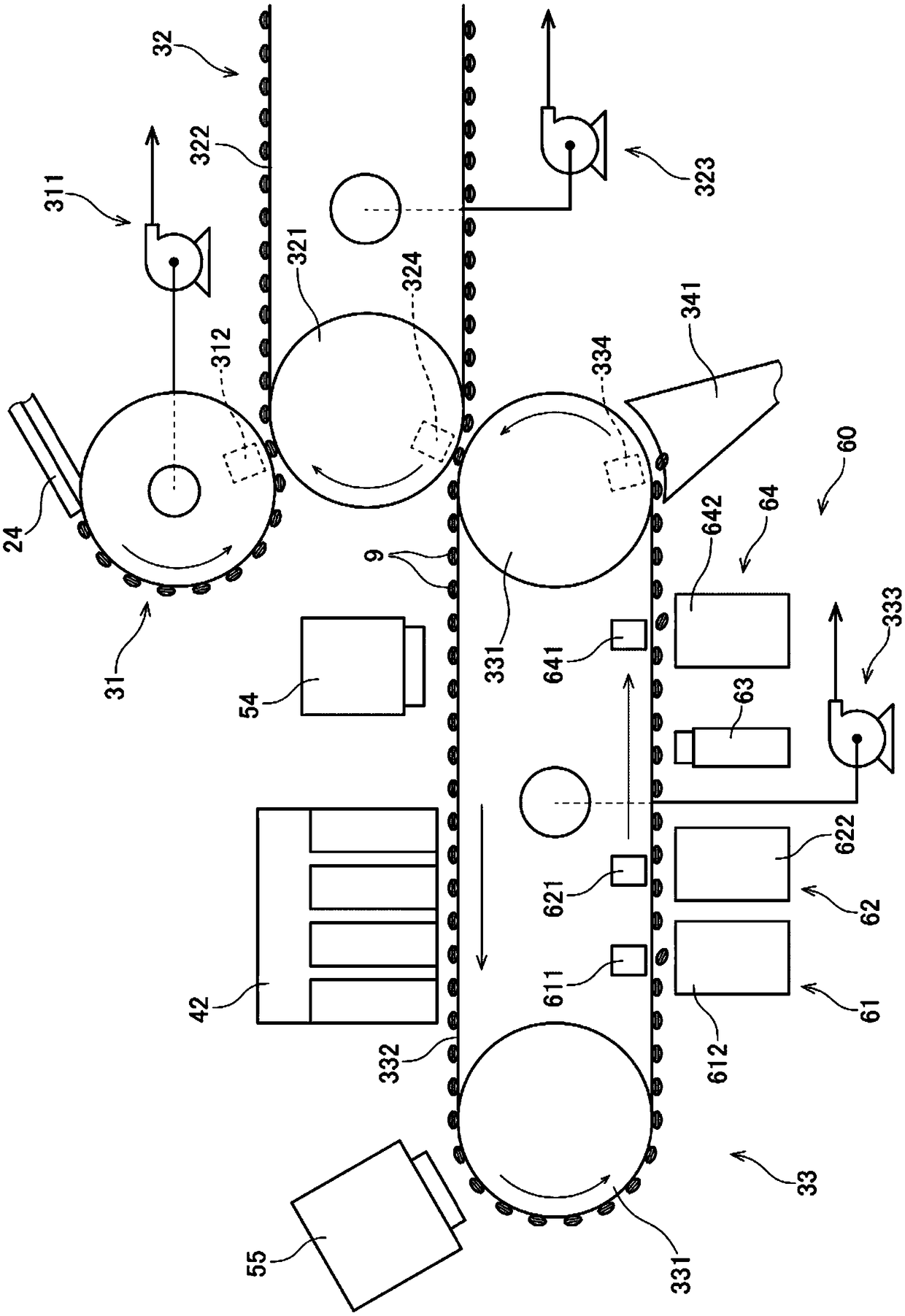

[0134] Figure 9 It is a diagram showing the configuration of a tablet printing apparatus 1A according to the third embodiment. Figure 10 It is a partial schematic diagram which shows the structure of the conveyance roller 31, part of the 1st conveyance belt 32, and the 2nd conveyance belt 33 in 3rd Embodiment. Figure 11 It is a block diagram showing the connection between the control unit 10A and each part in the tablet printing apparatus 1A in the third embodiment.

[0135] Figure 9 ~ Figure 11 In , the same reference numerals are assigned to the same configurations as those of the first embodiment. First, differences between the tablet printing apparatus 1A of the third embodiment and the tablet printing apparatus 1 of the first embodiment will be described.

[0136] Such as Figure 9 ~ Figure 11 As shown, in the tablet printing apparatus 1A, the recovery unit 60A does not have a discharge sensor. Correspondingly, as Figure 11 As shown, the control unit 10A does n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com