Embedded reflective eyepiece

A technology of eyepieces and reflectors, applied in magnifying glasses, instruments, optics, etc., to achieve the effect of reducing chromatic aberration and improving the performance of eyepieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention relates generally to reflective collimating eyepieces, and methods of forming magnified and collimated images. "Embedded" is a reference to the single monolithic nature of an optical design in which reflective elements are embedded or incorporated on both outer surfaces.

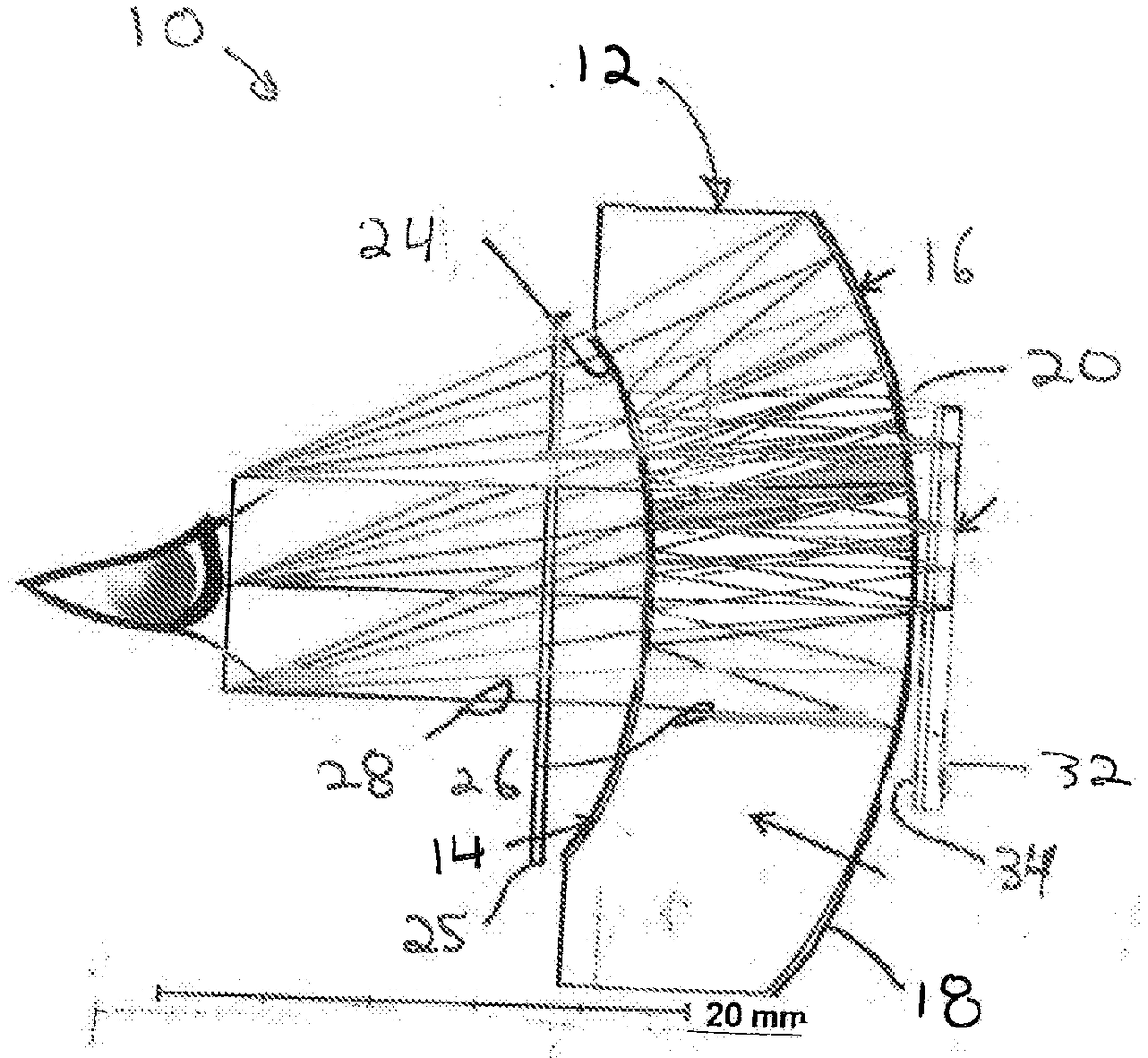

[0021] In one embodiment of the present invention, as figure 1 As shown, reflective collimating eyepiece 10 includes optical lens 12 . Optical lens 12 defines a concave surface 14 and a convex surface 16 opposite concave surface 14 . A beam splitter reflective coating 18 is located at the convex surface 14 . Typically, this is a dielectric coating with about a 50:50 coating performance ratio. 50:50 refers to the ratio or split ratio between reflected light and transmitted light at the beam splitter coating. Other ratios or reflective splits are also possible. The coating is designed to maintain the polarization of both transmitted and reflected polarized light. It can also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com