Device and system used for multi-lifting-point lifting

A multi-hoisting point and hoisting technology, applied in fluid pressure actuating devices, transportation and packaging, load hoisting components, etc., can solve the problems of high labor intensity, low work efficiency, low safety and reliability of operators, and improve operation. Efficiency, reduce labor intensity, and ensure the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

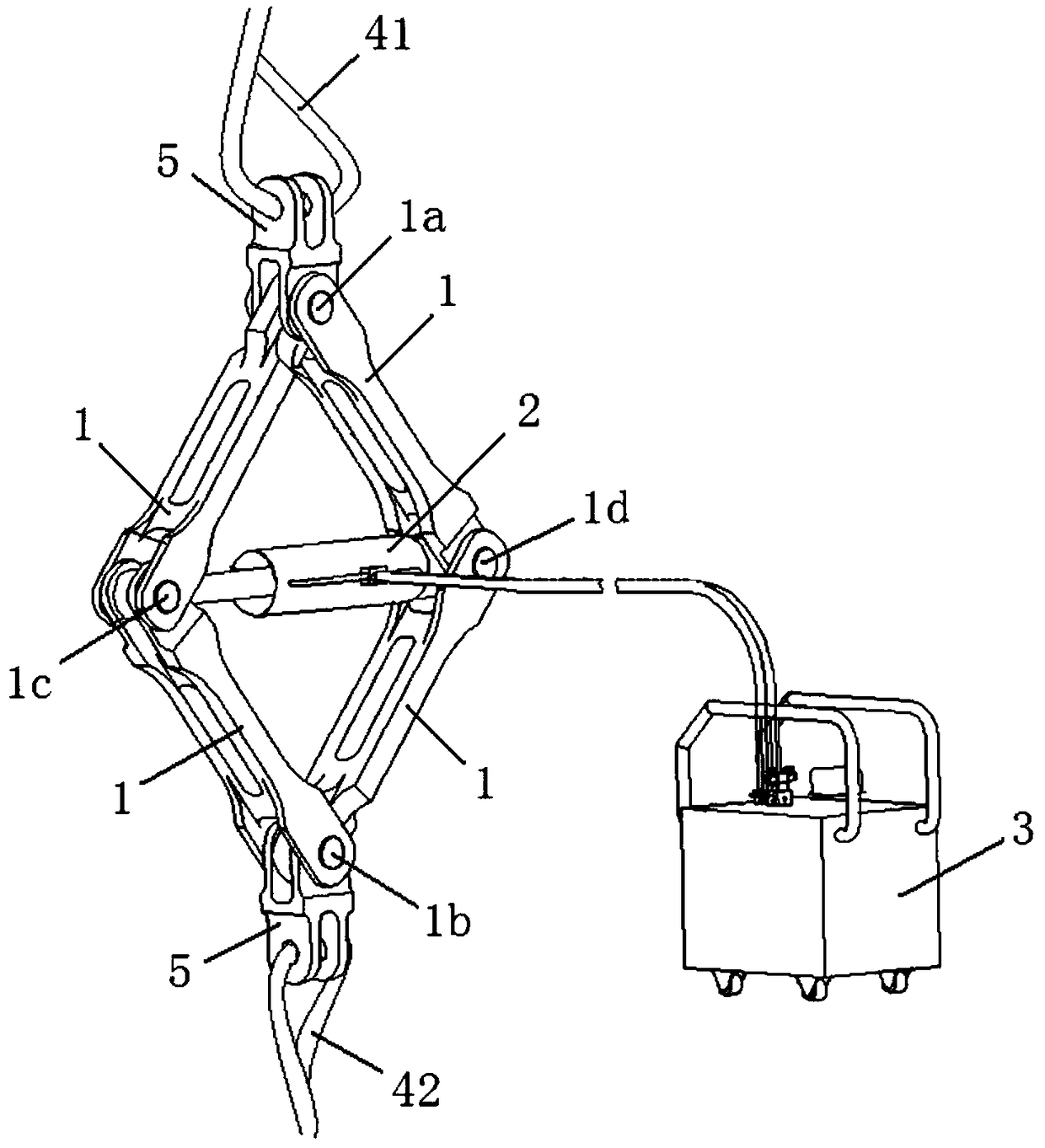

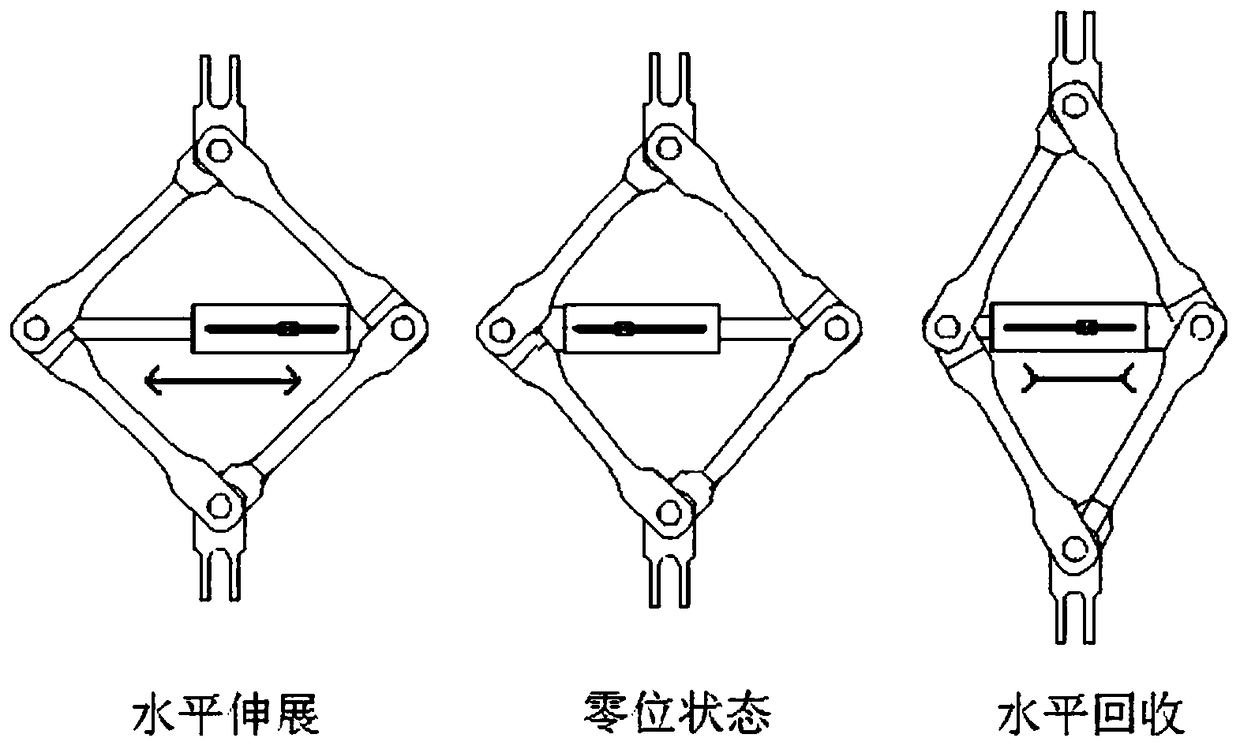

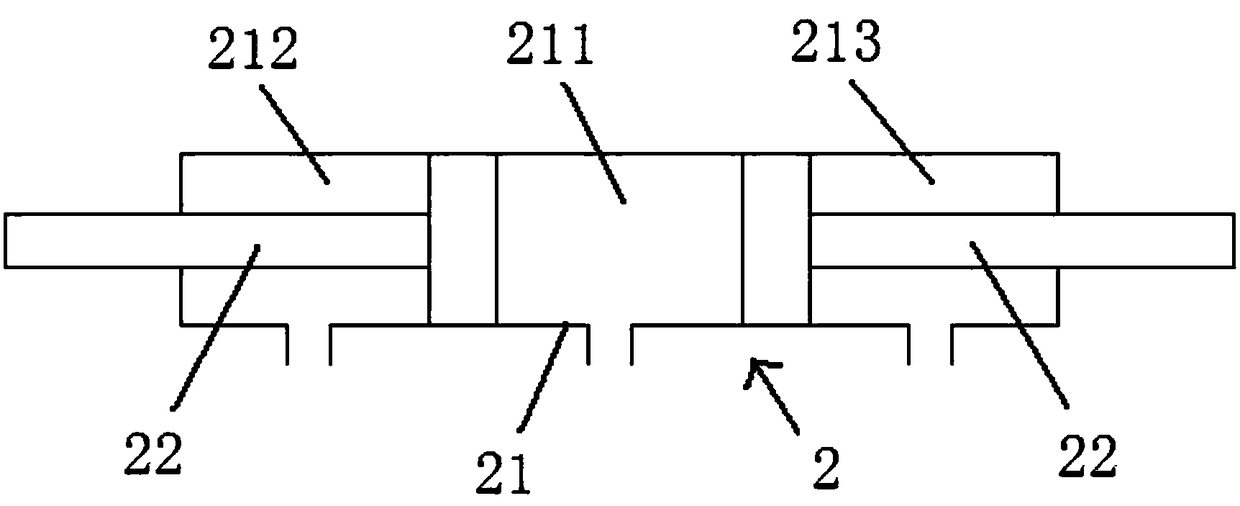

[0023] to combine figure 1 As shown, the device for multi-suspension hoisting in this embodiment includes four connecting rods 1 , one oil cylinder 2 and one hydraulic power unit 3 . Among them, the four connecting rods 1 are sequentially connected end-to-end through pin shafts to form a four-link structure. The oil cylinder 2 is located inside the four-bar structure and the two ends of the oil cylinder 2 are respectively connected to the two opposite ends of the four-bar structure. Junction points connect. When the four-bar linkage structure is placed in the vertical direction and connected with the rigging, the highest connection point 1a and the lowest connection point 1b in the four-bar linkage structure are connected to the upper rigging 41 and the lower rigging 42 respectively, and the two in the middle area The conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com