Spheroidizing annealing furnace

A technology of spheroidizing annealing furnace and furnace mouth, which is applied in the direction of furnace, heat treatment furnace, furnace type, etc. It can solve the problems of different annealing degree of steel, large temperature difference between upper and lower, which affects processing and use, and achieve uniform annealing effect and temperature difference. Small, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

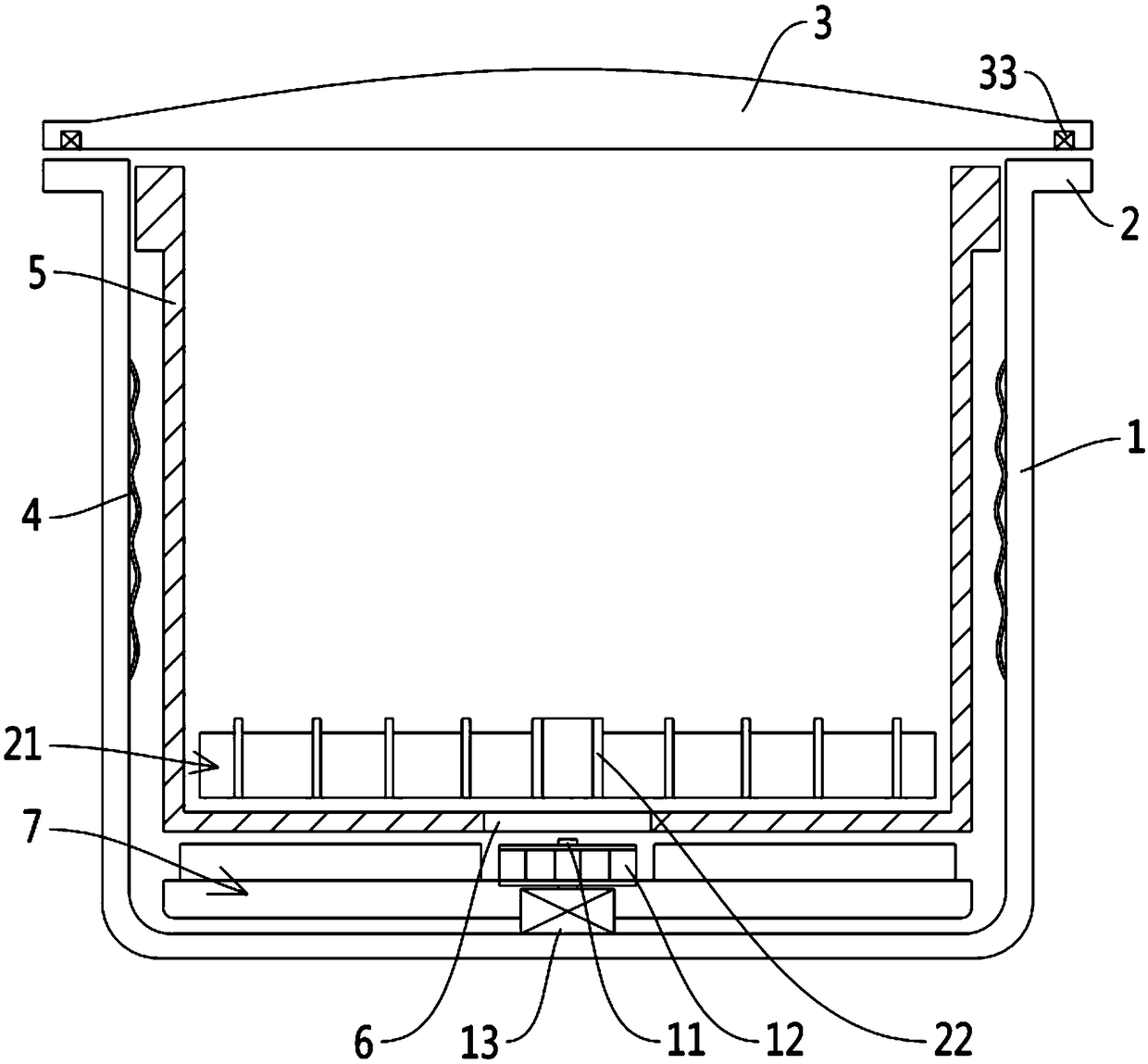

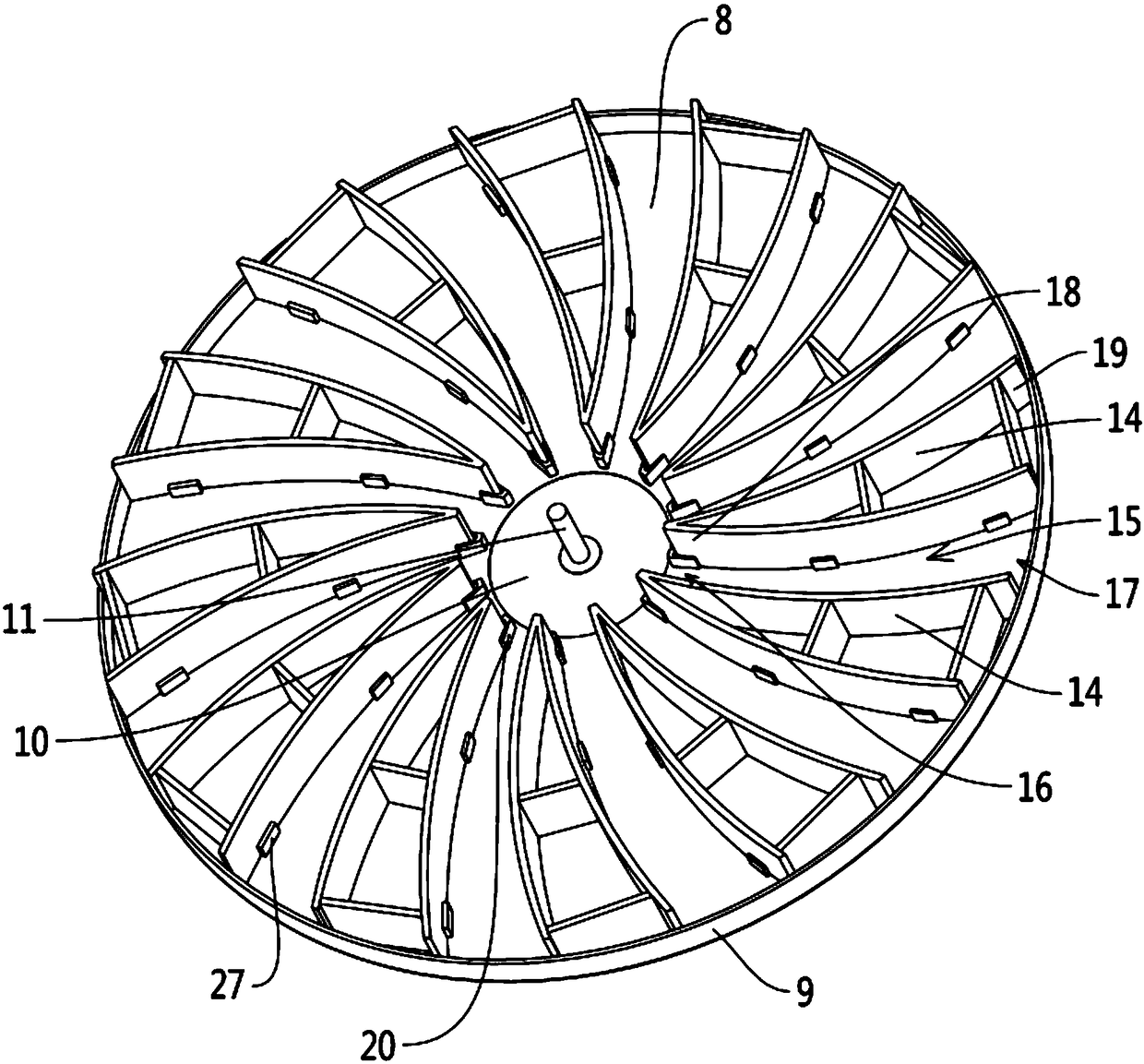

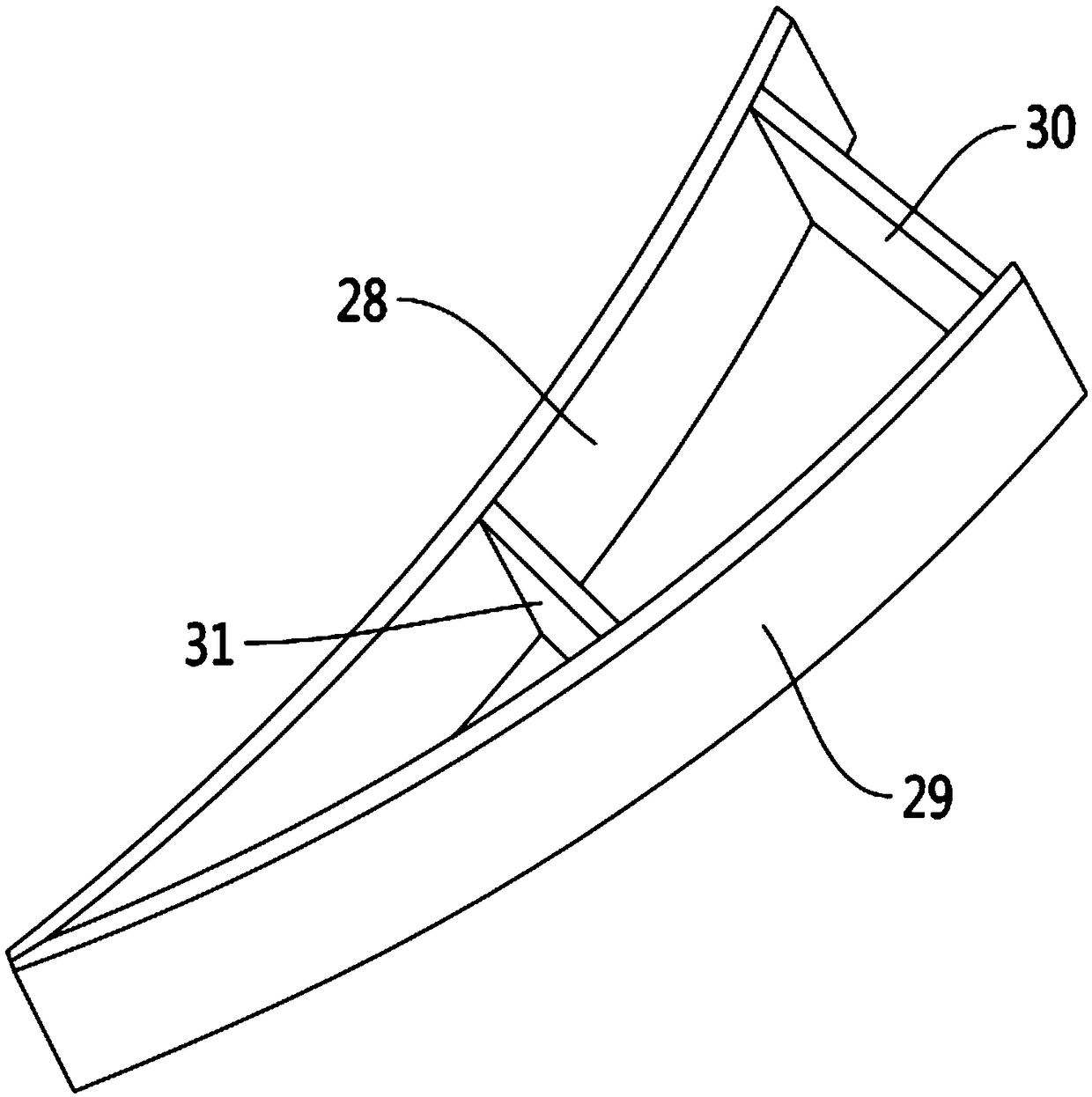

[0018] see Figures 1 to 5 As shown, a spheroidizing annealing furnace involved in this embodiment includes an outer furnace body 1 with the furnace mouth facing upwards, the outer furnace body 1 has a shoulder 2, and the outer furnace body 1 is also provided with a furnace cover 3, The inner wall of the outer furnace body 1 is provided with an electric heating wire 4, the outer furnace body 1 is provided with an inner furnace body 5, the bottom of the inner furnace body 5 has a vent 6, and the inner bottom of the outer furnace body 1 is There is a guide frame 7 located below the inner furnace body 5, the guide frame 7 includes a guide base plate 8, the edge of the guide base plate 8 has a vertically raised flange 9, and the center of the guide base plate 8 has a wind wheel installation area 10. In the center of the wind wheel installation ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com