Fore bracket for fully-mechanized mining face

A fully-mechanized mining face and advanced support technology, which is applied in the field of coal mining equipment, can solve the problems of easy damage to equipment, narrow roadways, and low coal seams, and achieve the goals of reducing the shape and weight, enhancing safety and reliability, and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

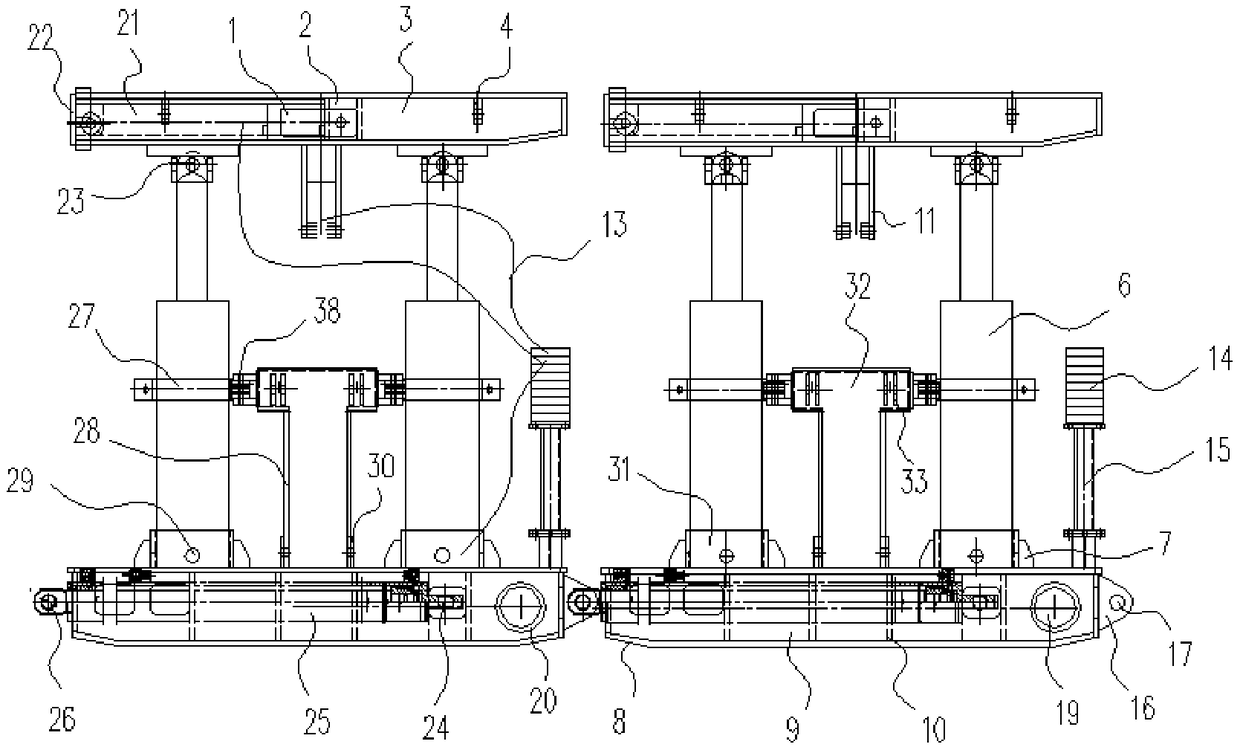

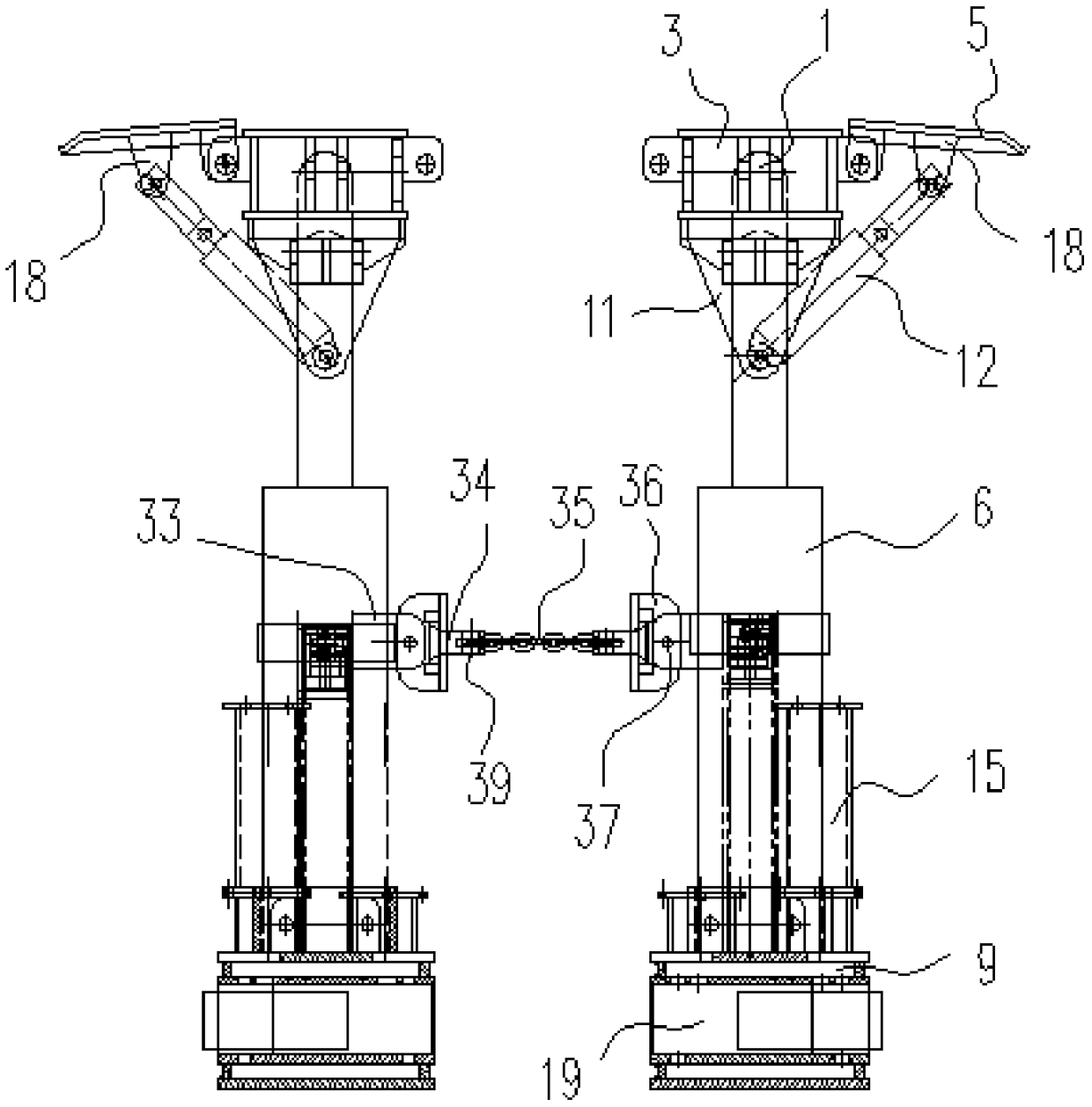

[0018] Embodiment 1: as attached Figure 1~2 Shown, a kind of advance support of fully mechanized mining face, it comprises base 9, oil cylinder one 6 and top frame 3, and described top frame 3 is positioned at the top of base 9 and is connected by two oil cylinders one 6 in the middle, on top frame 3 The upper end of the rear side is hinged with a side wall plate 5, and two symmetrical support plates 11 are fixedly connected in the middle below the top frame 3, and an oil cylinder 2 12 is hinged between the lower end of the support plate 11 and the bottom of the side wall plate 5, One end of the inside of the top frame 3 is provided with an oil cylinder three 1, an oil cylinder four 19 and an oil cylinder five 25 are arranged inside the base 9, and the side of the base 9 is fixedly connected with a valve seat rod 15, and the valve seat rod 15 is connected with several Reversing valve 14, described reversing valve 14 is respectively connected with oil cylinder one 6, oil cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com