Rice-grain sprout tray sprout feeding assembly line device

A technology of rice buds and flowing water, which is applied in the agricultural field, can solve the problems of unevenness, affecting the rice transplanter's popularization and use of rice production, and it is difficult to meet the requirements of machine transplanting, so as to achieve the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

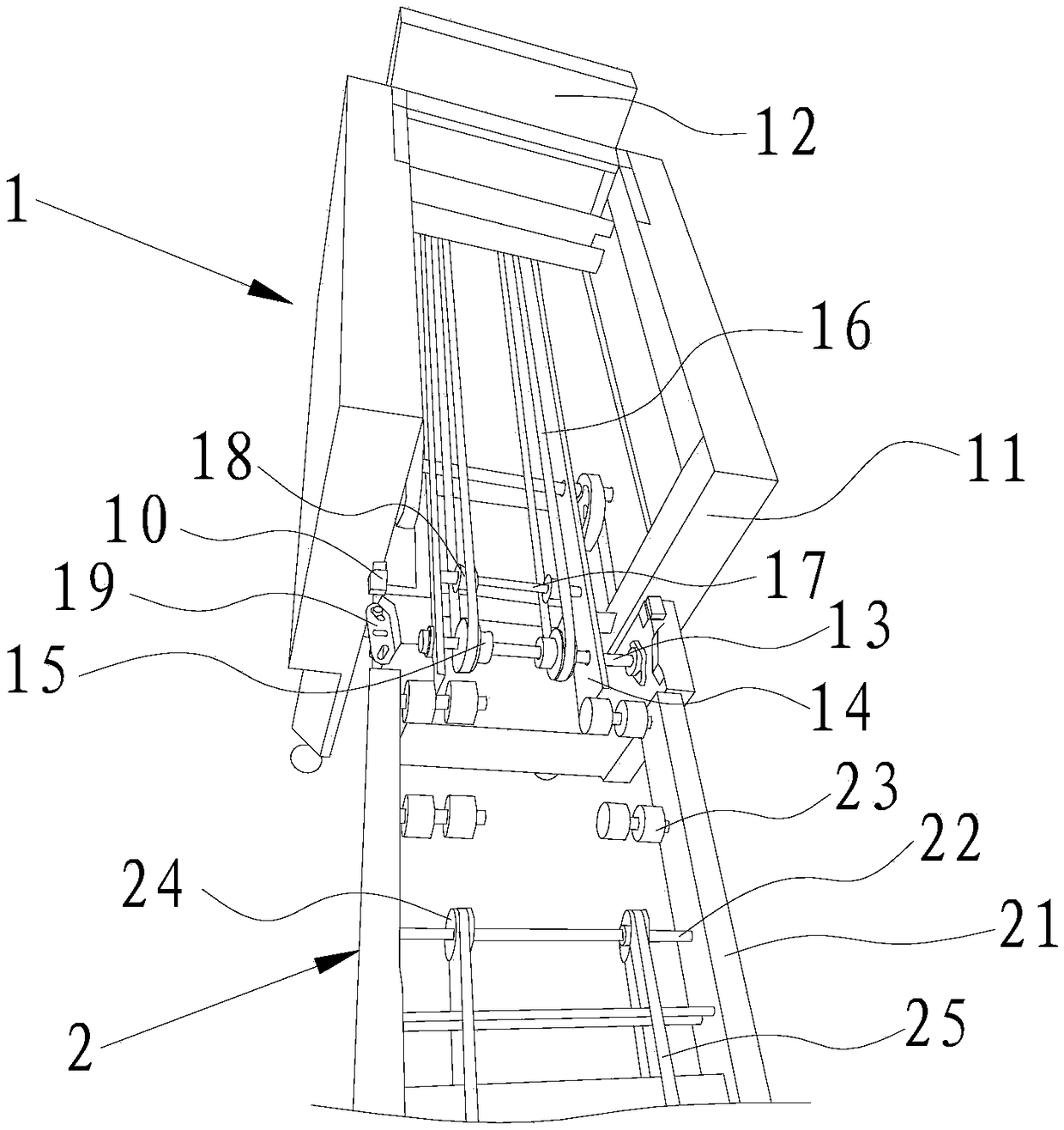

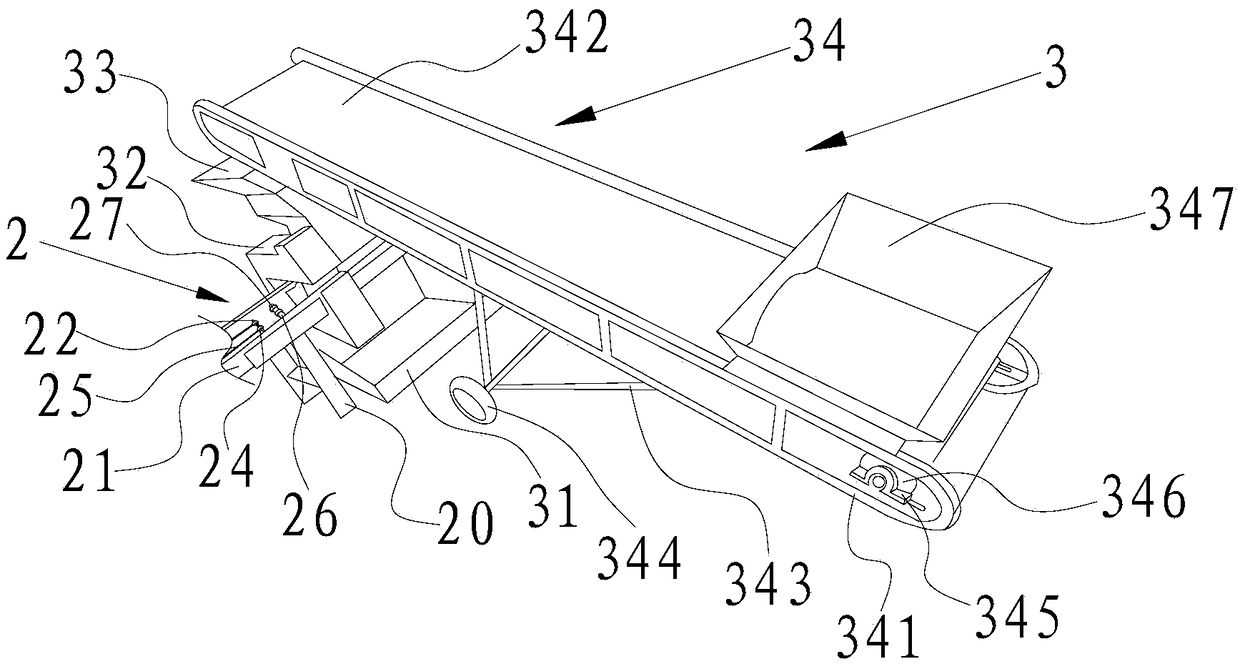

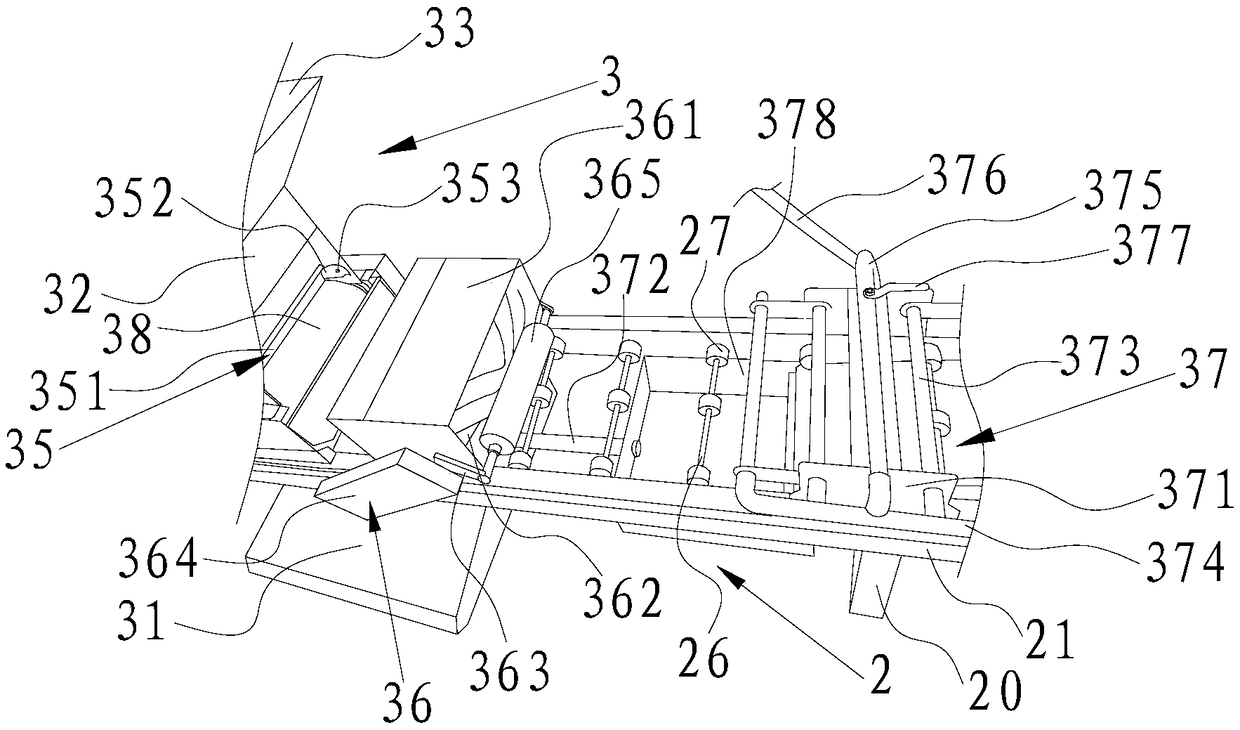

[0017] Such as Figure 1 to Figure 4 The bud feeding flow equipment shown on the rice bud tray mainly includes a tray feeding assembly 1, a tray conveying assembly 2, a matrix feeding assembly 3, and a rice bud feeding assembly 4, etc.

[0018] Wherein, the tray feeding assembly 1 includes two spacing frames 11 that are spaced and oppositely arranged (the two spacing frames 11 are spaced to form an accommodating space that can place a rice bud tray between them), integrally connected Side baffle 12 (side baffle 12 only has an end of two space-limiting frames 11 at two space-limiting frame bodies 11 ends, and the other end place of two space-limiting frame bodies 11 forms opening so that the rice bud dish move out), two first support plates 14 installed between two space-limiting frames 11 (a plurality of vertical poles can be connected bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com