Peanut picking and screening machine

A peanut picking and screening machine technology, applied in the field of agriculture, can solve the problems of affecting farming efficiency, increasing workload, difficult fruit seedling separation, etc., and achieve the effect of saving manpower and reducing labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

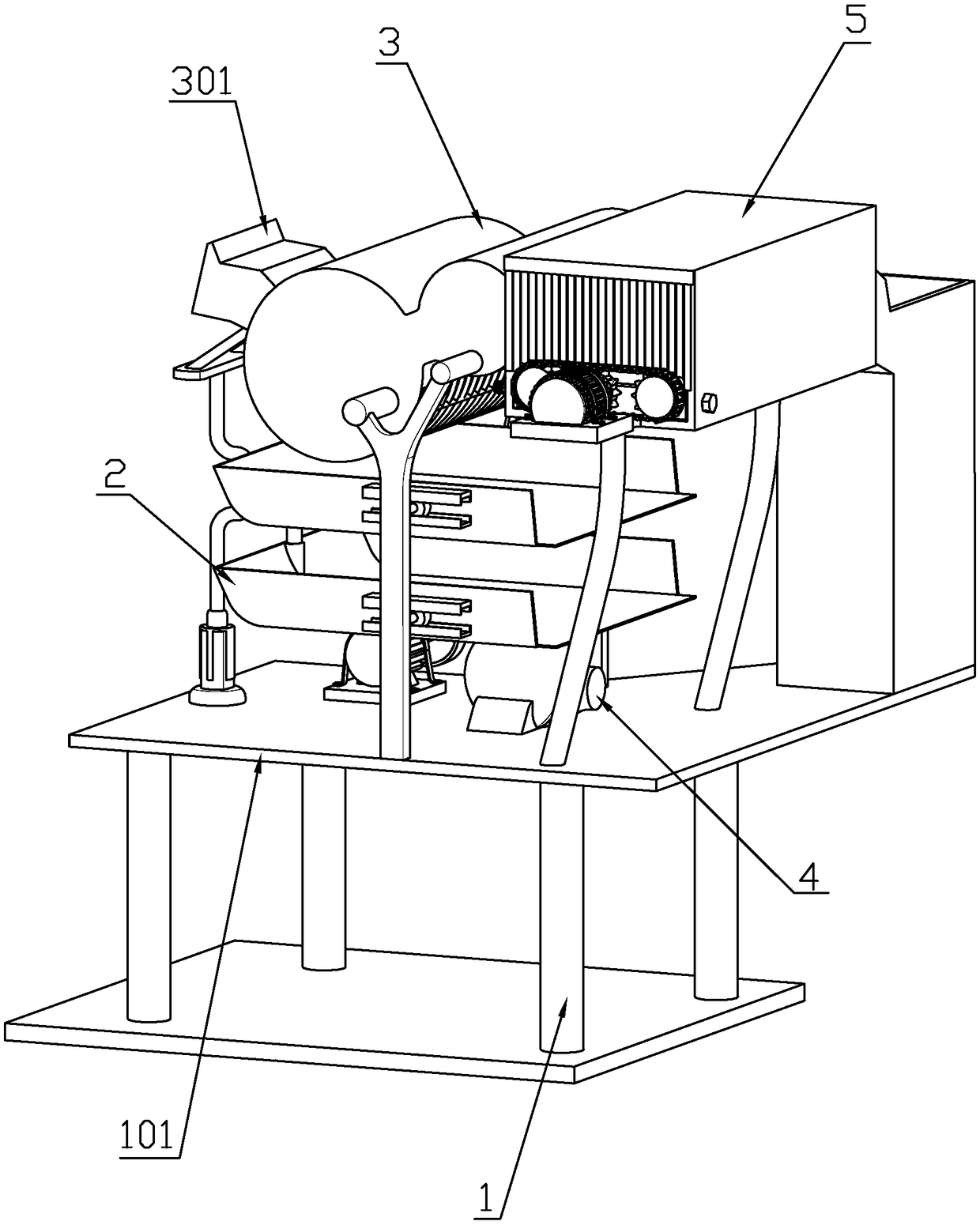

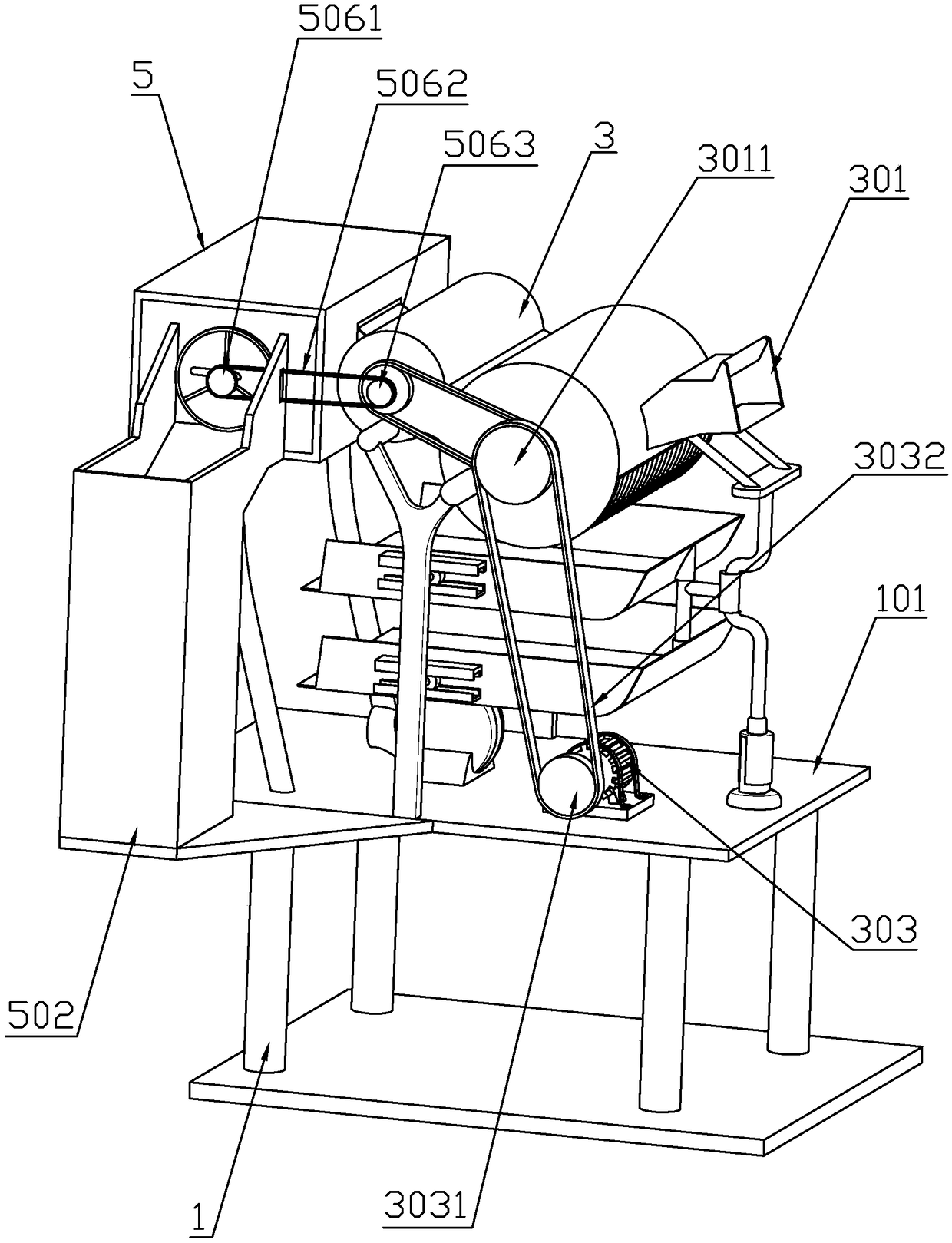

[0030] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-12 , to further specifically describe the technical solution of the present invention.

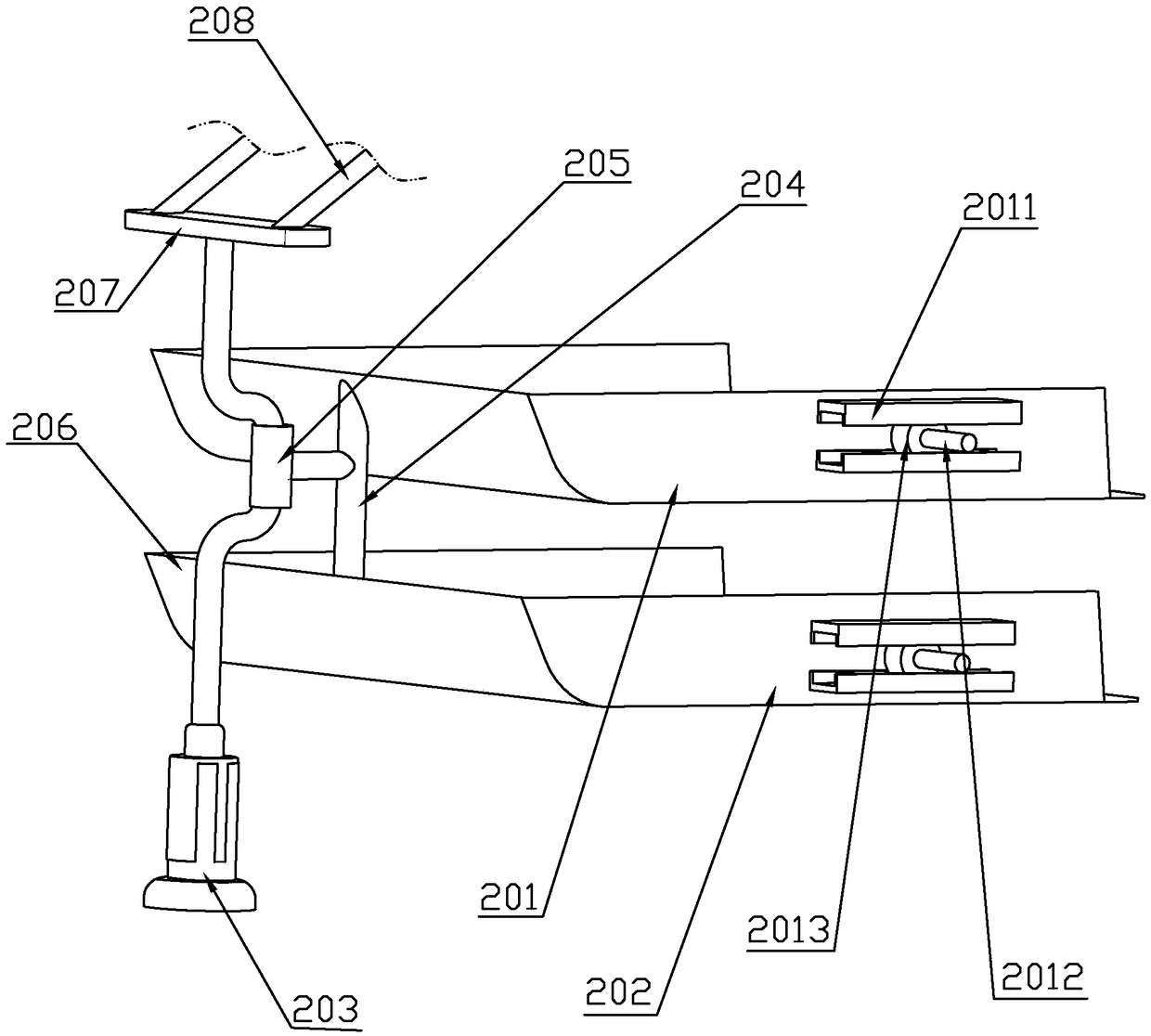

[0031] A peanut picking and screening machine, comprising a bracket 1, a screening mechanism 2, a body 3, a blower 4, and a film separation mechanism 5, the top of the bracket 1 is provided with a set plate 101, and one side of the set plate 101 is provided with a screening mechanism 2. The screening mechanism 2 includes an upper screen 201, a lower screen 202, a servo motor 203, and a crank rod 206. The servo motor 203 is fixed on one side of the plate 101, and the output shaft of the servo motor 203 is connected to the crank Rod 206, the curved part of the curved rod 206 is sleeved with a movable sleeve 205, one side of the movable sleeve 205 is connected to the connecting rod 204, and one end of the connecting rod 204 is rotatably connected to the upper screen 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com