Stainless steel flange turning blade

A stainless steel and blade technology, applied in the field of metal cutting, can solve the problem that the blade cannot take into account both roughing and finishing, and achieve good chip breaking effect, guaranteed strength, and the effect of expanding the scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

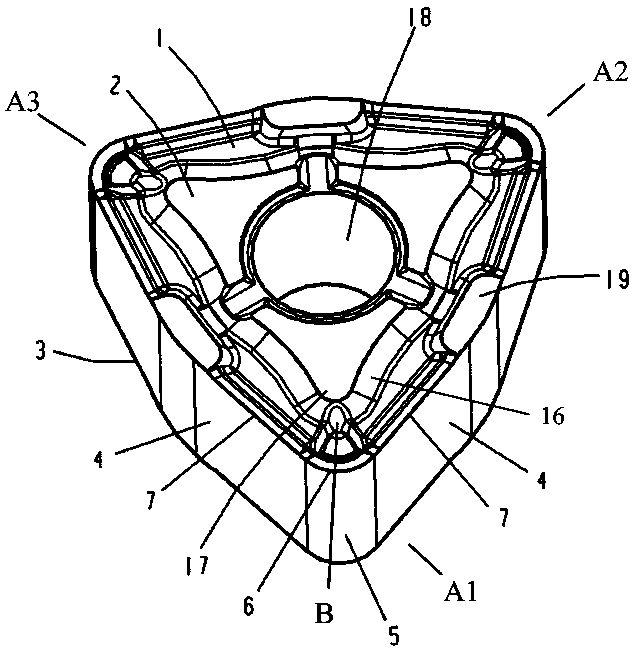

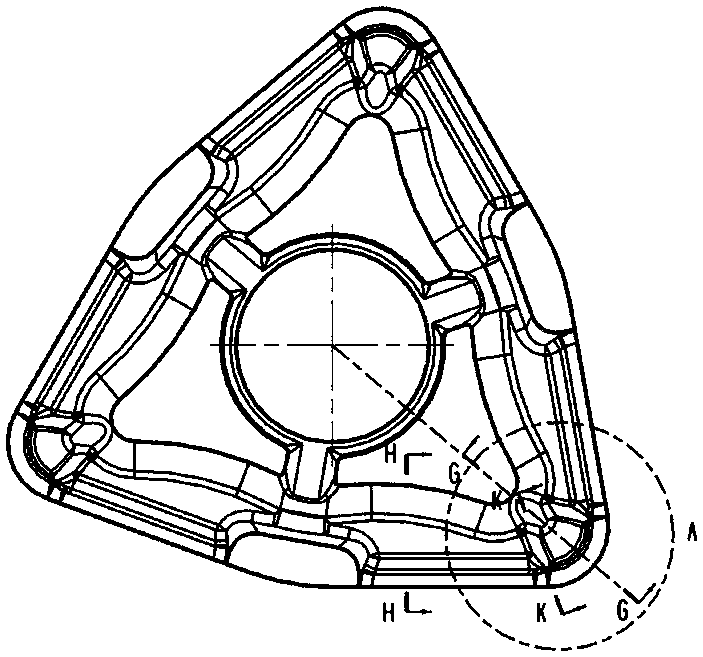

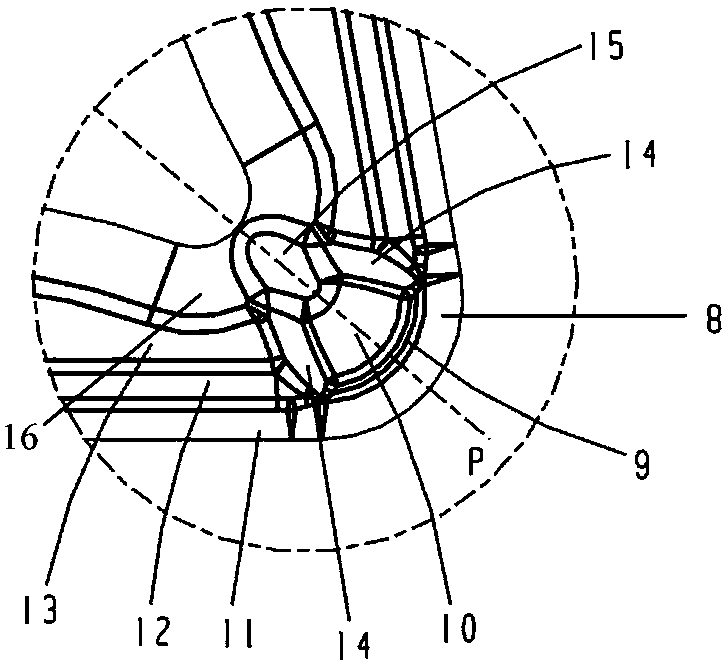

[0035] Such as figure 1 As shown, a turning blade for stainless steel flanges, the above-mentioned blade body 1 is provided with a positioning center hole 18 at its geometric center; the blade body 1 is a polygonal body. The geometric structure of a hexagon that is approximately equilateral and not equiangular; the above-mentioned blade body 1 includes an upper surface 2, a lower surface 3, a plurality of side surfaces 4, and an arc surface 2 between two adjacent side surfaces 4 ; The blade body 1 is provided with a positioning center hole 18 located at its geometric center;

[0036] The upper surface 2 of the blade body 1 is evenly provided with a plurality of protrusions-17 along the periphery of the positioning center hole 18; on the outside of the two adjacent protrusions-17, and at the place where the two side surfaces 4 intersect to form an obtuse angle and the upper The central point of the junction of the surfaces 2 is provided with a protrusion 2 19 . In the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com