Aviation radial tire

A technology for radial tires and aviation, applied to special tires, tire parts, reinforcement layers of pneumatic tires, etc., can solve the problems of reducing bead durability, bead bursting, bead delamination, etc., to increase mechanical properties, The effect of reducing internal cracks and preventing cord loosening and delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

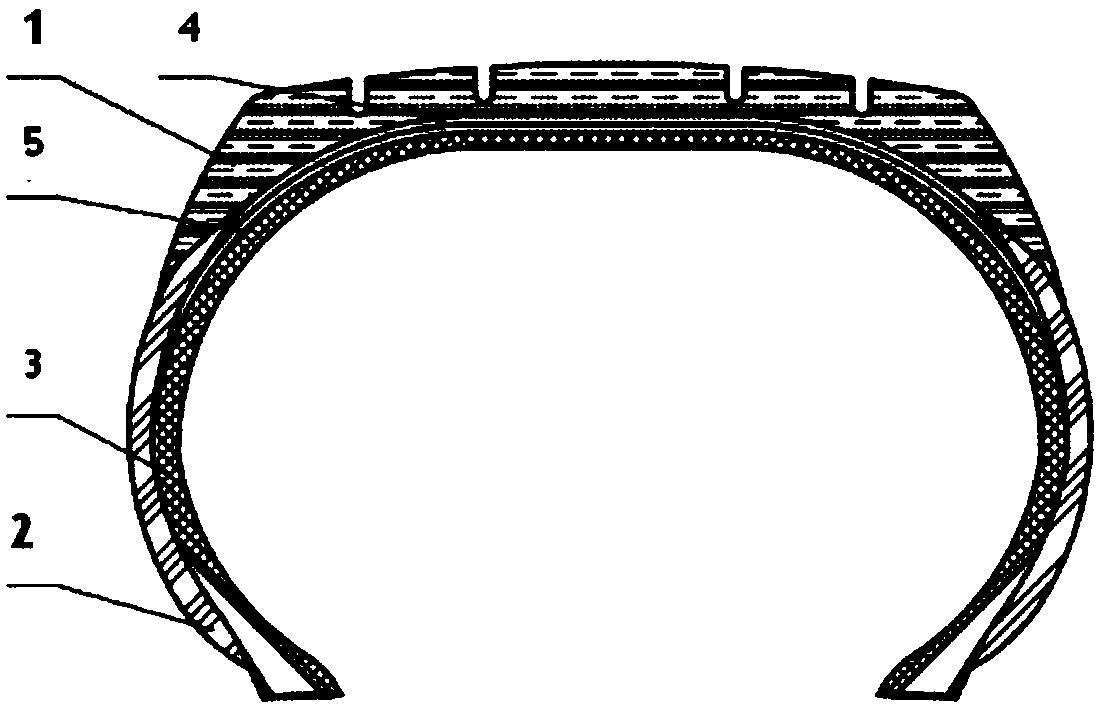

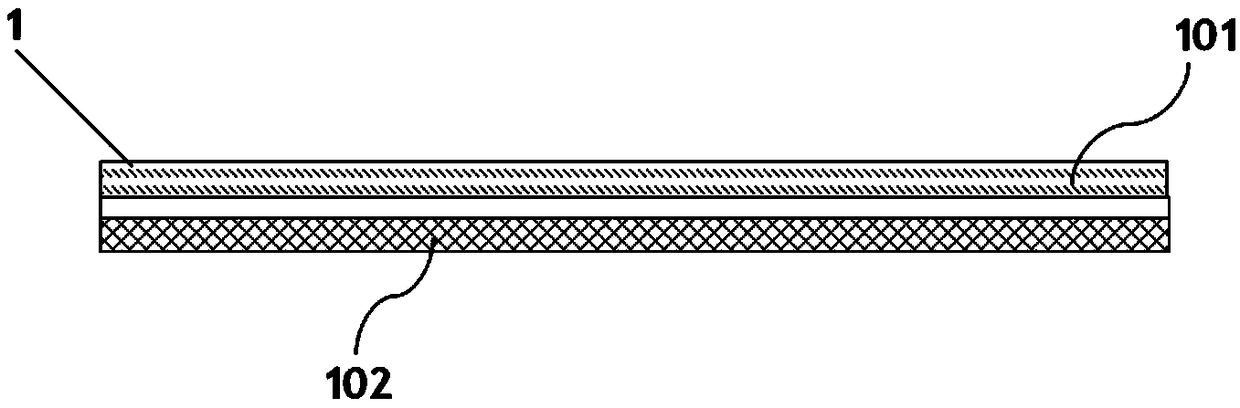

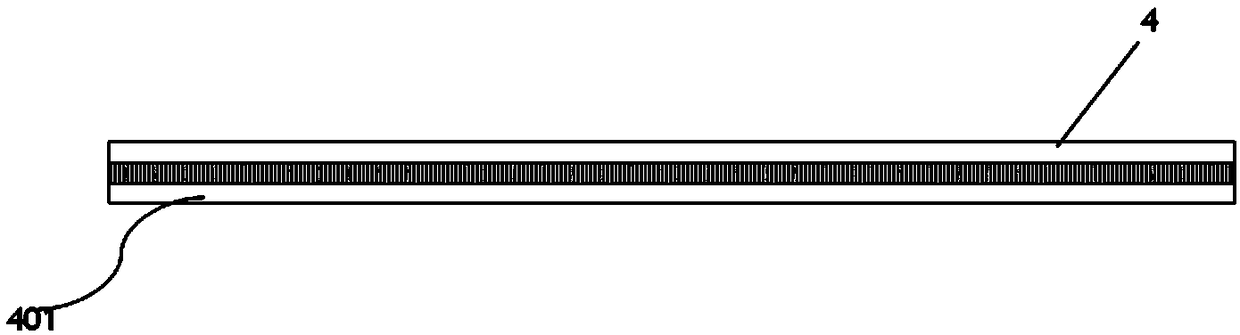

[0022] Such as Figure 1 to 3 As shown, an aviation radial tire includes a carcass, the carcass includes a tread rubber layer 1, a sidewall layer 2, an inner liner layer 3, a bead layer 4 and a crown reinforcement 5, and a tread rubber layer 1 Adhesive layers of different structures are bonded into one body. Between the tread rubber layer 1 and the inner liner 3, a bead layer 4 composed of several traveler rings arranged in parallel and a crown reinforcement member 5 are arranged in sequence. Multiple traveler rings The steel wires are connected together to form a steel wire mesh. The steel wire mesh is provided with a filler rubber strip 401. The crown reinforcement 5 includes a plurality of first belt layers made of carbon cellulose distributed in parallel, on both sides of the first belt layer. It is connected to the sidewall layer 2, the end of the rubber filler strip 401 overlaps the connection between the first belt layer and the sidewall layer 2, and the contact surface ...

Embodiment 2

[0030] Referring to Example 1, the difference between the aero radial tire provided in this example is that the rubber surface layer 101 is made of rubber, and the rubber composition includes the following components by weight: 50 parts of oil-extended rubber, 10 parts of benzene rubber, 25 parts of butadiene rubber, 10 parts of polyisoprene rubber, 20 parts of carbon black, 1 part of zinc stearate; 55 parts of naphthenic rubber oil are filled in every 100 parts of rubber.

Embodiment 3

[0032] Referring to Example 1, the difference between the aero radial tire provided in this example is that the rubber surface layer 101 is made of rubber, and the rubber composition includes the following components by weight: 100 parts of oil-extended rubber, 30 parts of benzene rubber, 30 parts of butadiene rubber, 30 parts of polyisoprene rubber, 40 parts of carbon black, 8 parts of zinc stearate; of which 50 parts of naphthenic rubber oil are filled in every 100 parts of rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com