Heat preservation box for cold-chain transportation

A technology of cold chain transportation and heat preservation box, which is applied in the direction of heat preservation container, transportation and packaging, application, etc., can solve the problem that the heat preservation box cannot take into account the strength and heat preservation performance, and achieve the effect of close heat preservation performance, excellent strength, and improved heat preservation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

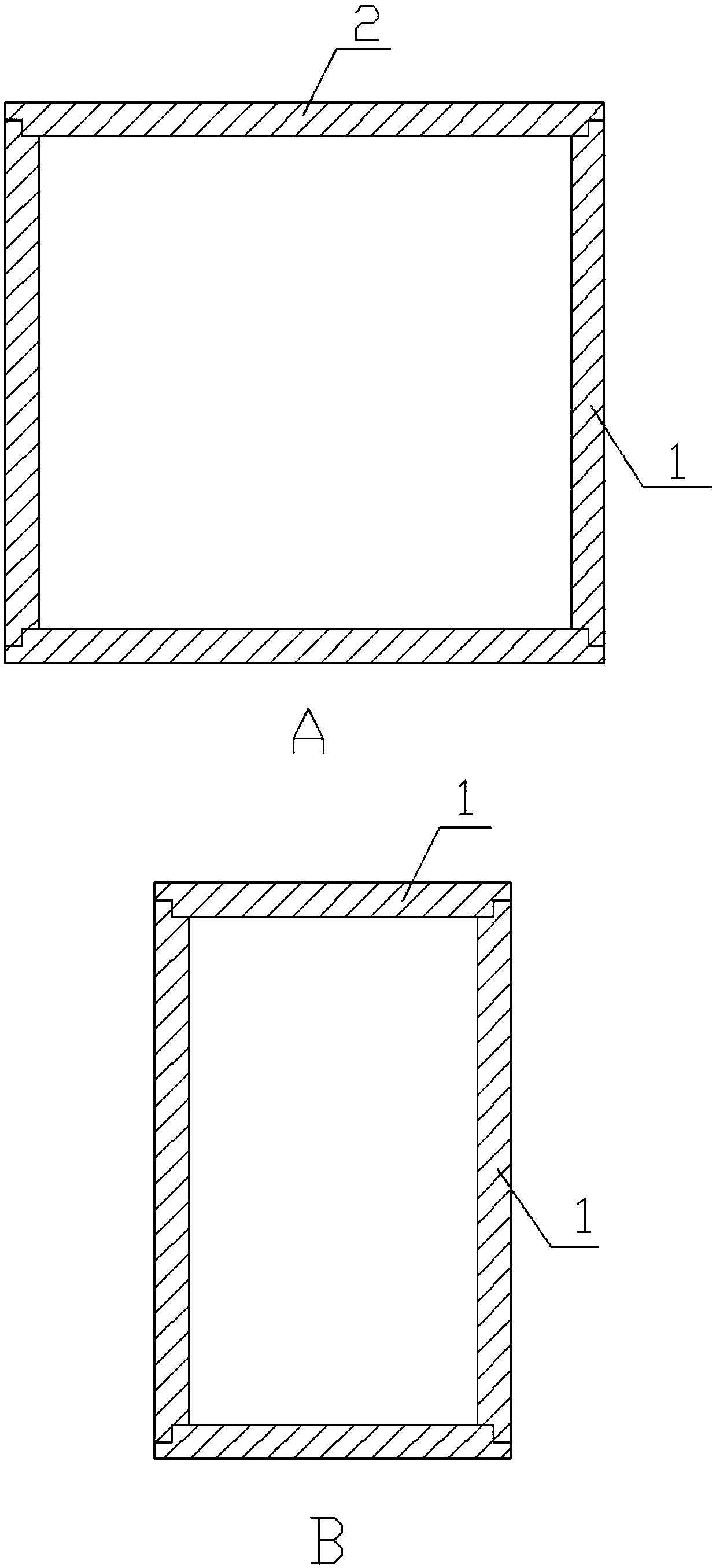

[0029] Such as figure 1 An insulated box for cold chain transportation shown includes a box body 1 and a box cover 2 composed of an insulation layer. The box body is assembled from the insulation layer. Board 3, outer honeycomb layer 4, foam layer 5, inner honeycomb layer 6, inner guard plate 7 ( Figure 5 ), the outer side of the outer guard plate seals the outer honeycomb layer, the inner guard plate seals the inner side of the inner honeycomb layer, and the outer side of the foam layer is filled in the honeycomb channel 8 of the outer honeycomb layer and seals the outer honeycomb layer The inner side of the foam layer is filled into the honeycomb channels of the inner honeycomb layer and the outer side of the inner honeycomb layer is closed. The foaming material of the foam layer is polyurethane; the filled volume of the honeycomb channels of each outer honeycomb layer accounts for 2%-35% of the total volume of the honeycomb channels of each outer honeycomb layer; the fill...

Embodiment 2

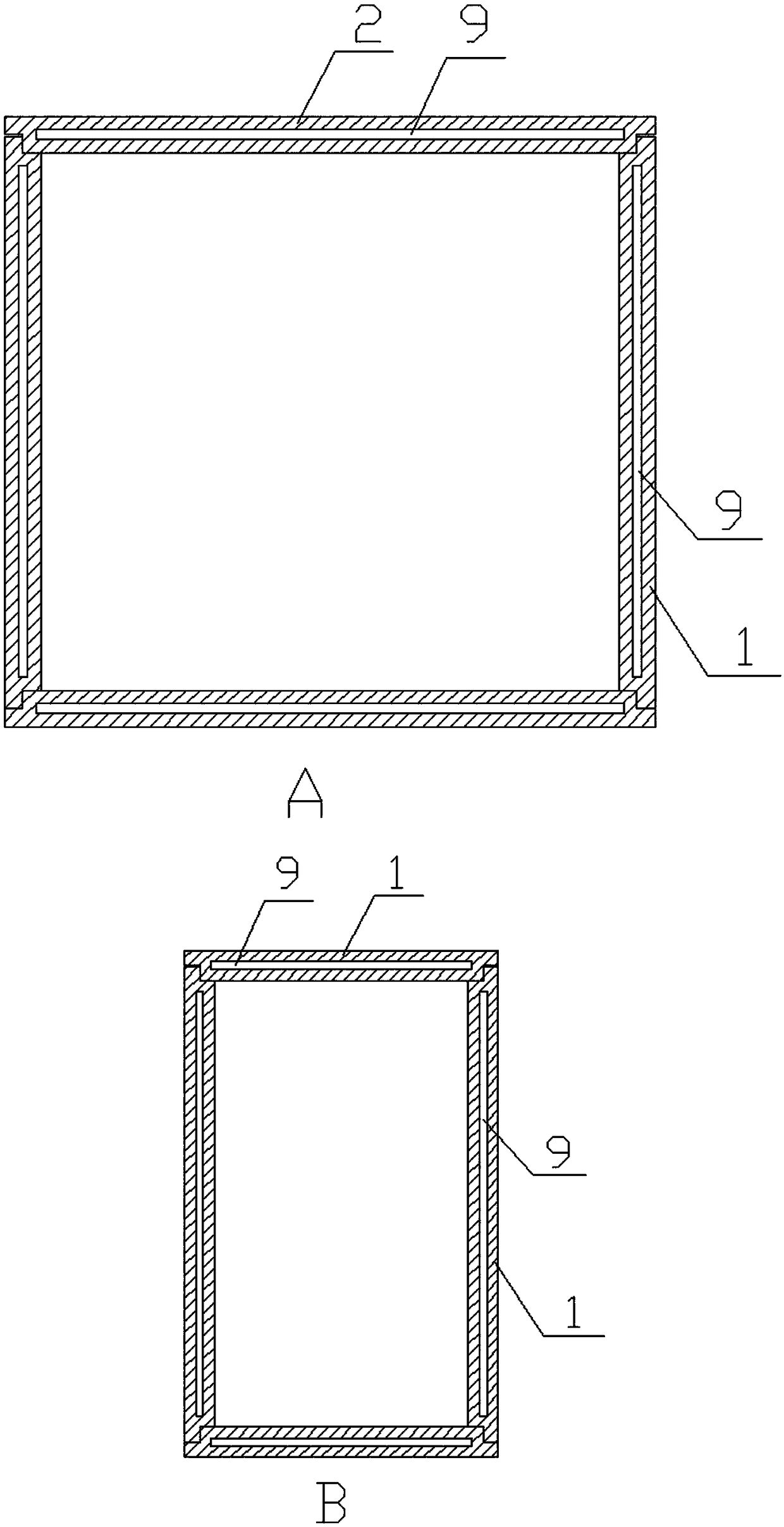

[0031] Such as figure 2 An insulated box for cold chain transportation shown includes a box body 1 and a box cover 2 composed of an insulation layer. The box body is assembled from the insulation layer. Board 3, outer honeycomb layer 4, foam layer 5, inner honeycomb layer 6, inner guard plate 7, and the middle part of the foam layer is provided with a vacuum insulation board 9 ( Image 6 ), the outer side of the outer guard plate seals the outer honeycomb layer, the inner guard plate seals the inner side of the inner honeycomb layer, and the outer side of the foam layer is filled in the honeycomb channel 8 of the outer honeycomb layer and seals the outer honeycomb layer The inner side of the foam layer is filled into the honeycomb channels of the inner honeycomb layer and the outer side of the inner honeycomb layer is closed. The foaming material of the foam layer is polyurethane; the filled volume of the honeycomb channels of each outer honeycomb layer accounts for 2%-35% o...

Embodiment 3

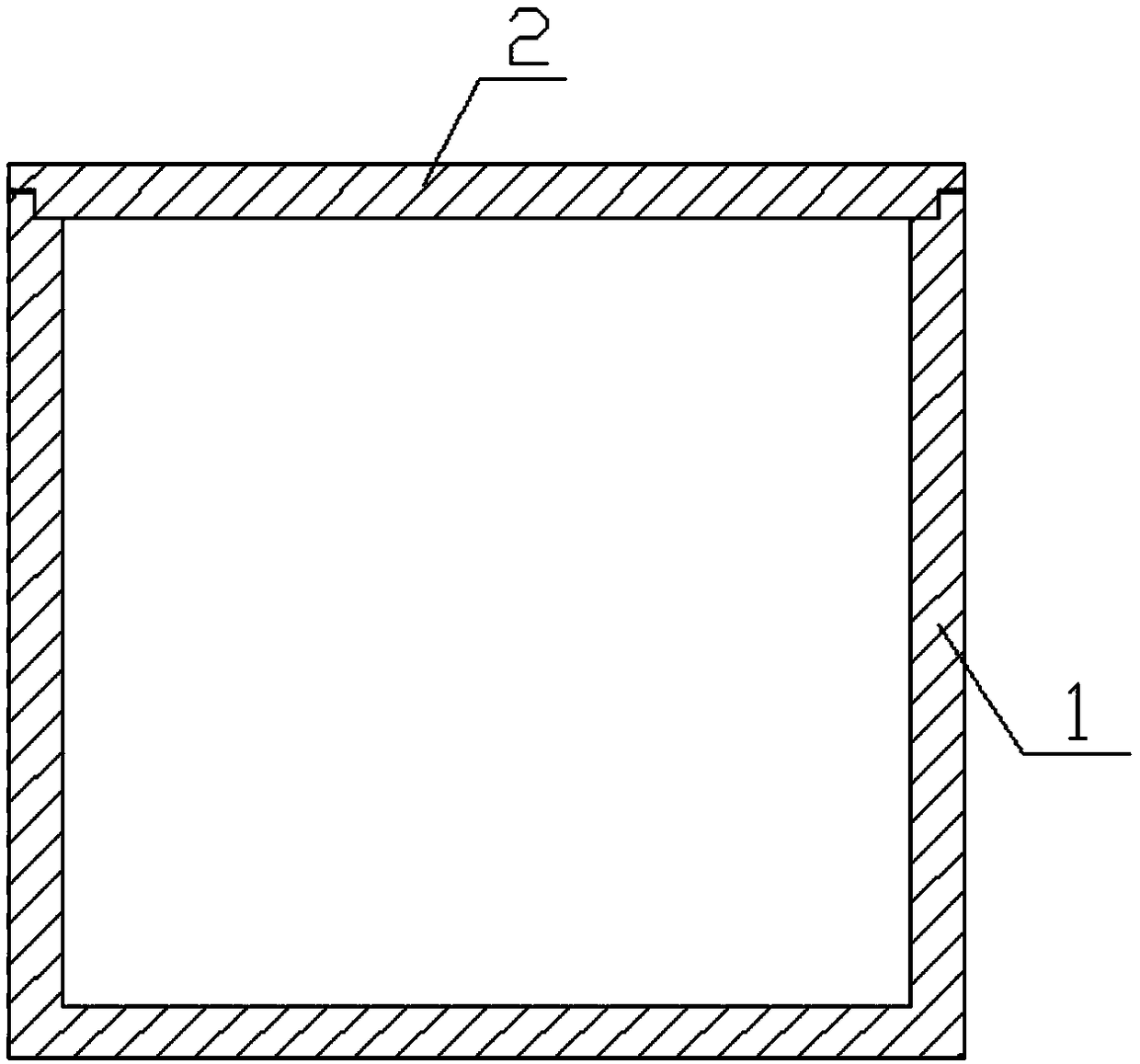

[0033] Such as image 3 An insulated box for cold chain transportation shown includes a box body 1 and a box cover 2 composed of an insulation layer. The box body is composed of an integrally formed insulation layer. Guard plate 3, outer honeycomb layer 4, foam layer 5, inner honeycomb layer 6, inner guard plate 7 ( Figure 5 ), the outer side of the outer guard plate seals the outer honeycomb layer, the inner guard plate seals the inner side of the inner honeycomb layer, and the outer side of the foam layer is filled in the honeycomb channel 8 of the outer honeycomb layer and seals the outer honeycomb layer The inner side of the foam layer is filled into the honeycomb channels of the inner honeycomb layer and the outer side of the inner honeycomb layer is closed. The foaming material of the foam layer is polyurethane; the filled volume of the honeycomb channels of each outer honeycomb layer accounts for 2%-35% of the total volume of the honeycomb channels of each outer honey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com