A kind of cefotiam hydrochloride drying process

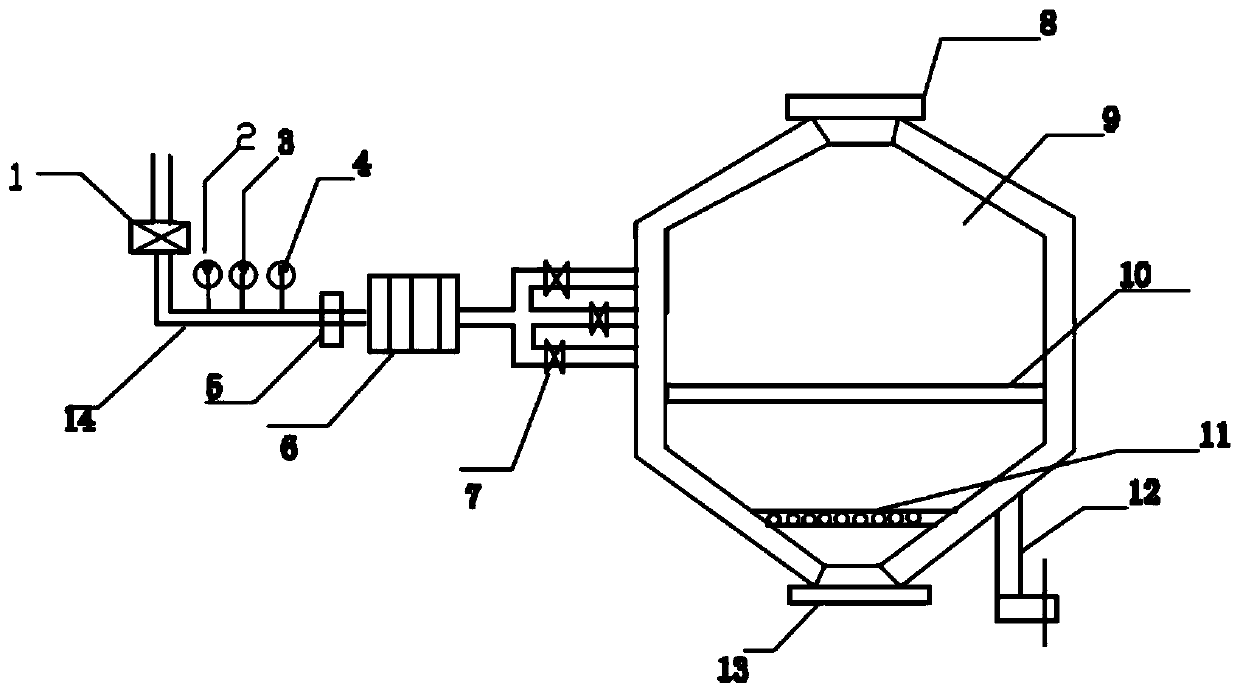

A technology of cefotiam hydrochloride and drying process, which is applied in the direction of drying gas arrangement, partial agitation dryer, static material dryer, etc. It can solve the problems of difficulty in reducing production costs, difficulty in reaching pharmacopoeia limits, high moisture content in products, etc. problems, to achieve the effect of simple operation, easy control of reaction temperature, high overall yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation of refined wet product of cefotiam hydrochloride:

[0031] a. 17.32kg (100mol) of 1-(2-dimethylaminoethyl)-1,2,3,4-tetrazole-5-thiol (DMMT), boron trifluoride-acetonitrile (250mol, according to BF 3 ), acetonitrile 100L, and butanol 50L were added to the reaction tank, and the temperature was controlled at 0-5°C, and 27.23kg (100mol) of 7-ACA was slowly added dropwise, controlled at 0-5°C and stirred for 1.5h. During the reaction, 200mol of 2M hydrochloric acid, after the reaction was completed, ethanol was added for crystallization, centrifuged, and double-cone drying to obtain 35.75kg of intermediate 1 with a yield of 92% and a purity of 99.2%;

[0032] B, 15.33kg (100mol) of phosphorus oxychloride, 80L acetonitrile, 20L N, N-dimethylformamide, 150mol triethylamine are dropped into reaction tank, then drop into aminothiazole acetic acid hydrochloride 19.46kg (100mol), Stirring reaction was carried out at -5~-10°C for 1 hour. After the reaction was com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com