Annealing device capable of preventing sparking and eliminating resistance for power cable

A technology for power cables and annealing devices, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as cable surface burns, inconsistent upper resistance, and sparking, so as to improve surface quality, ensure consistency, and reduce sparking The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

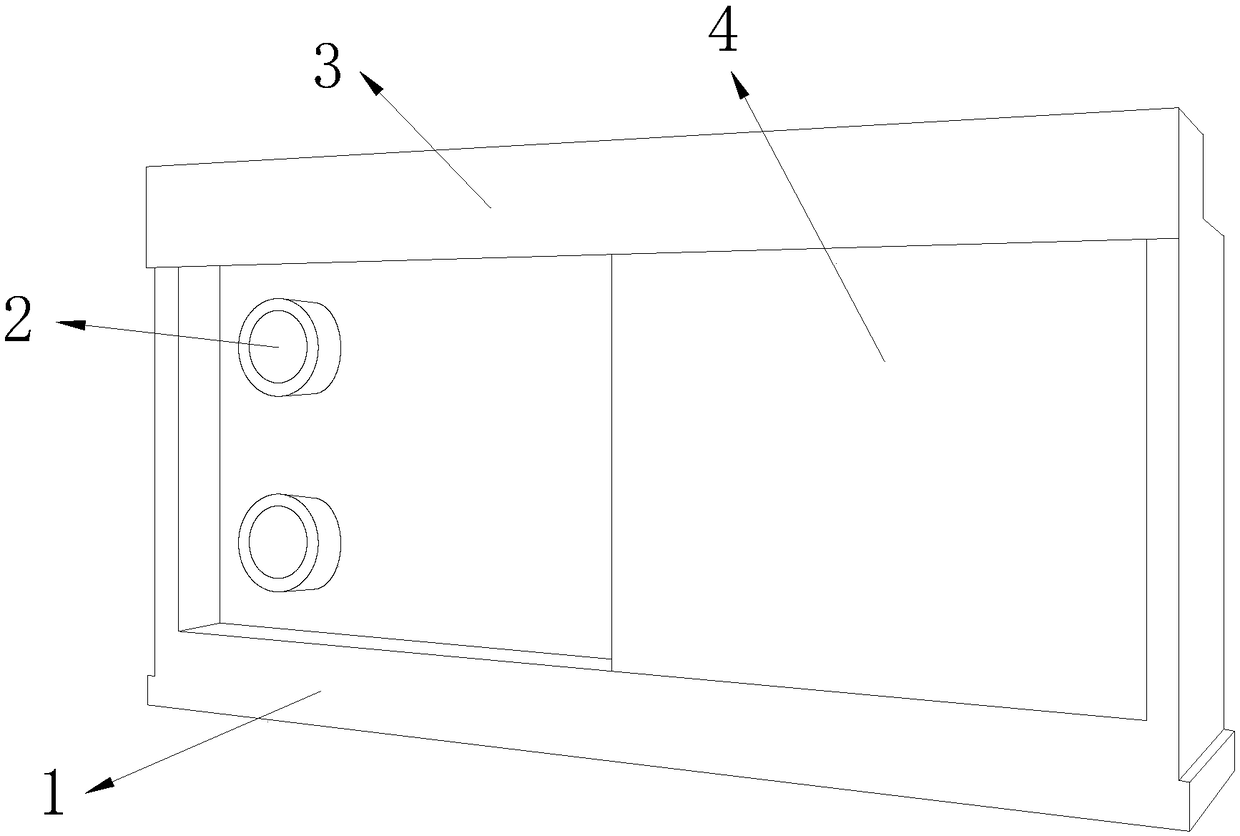

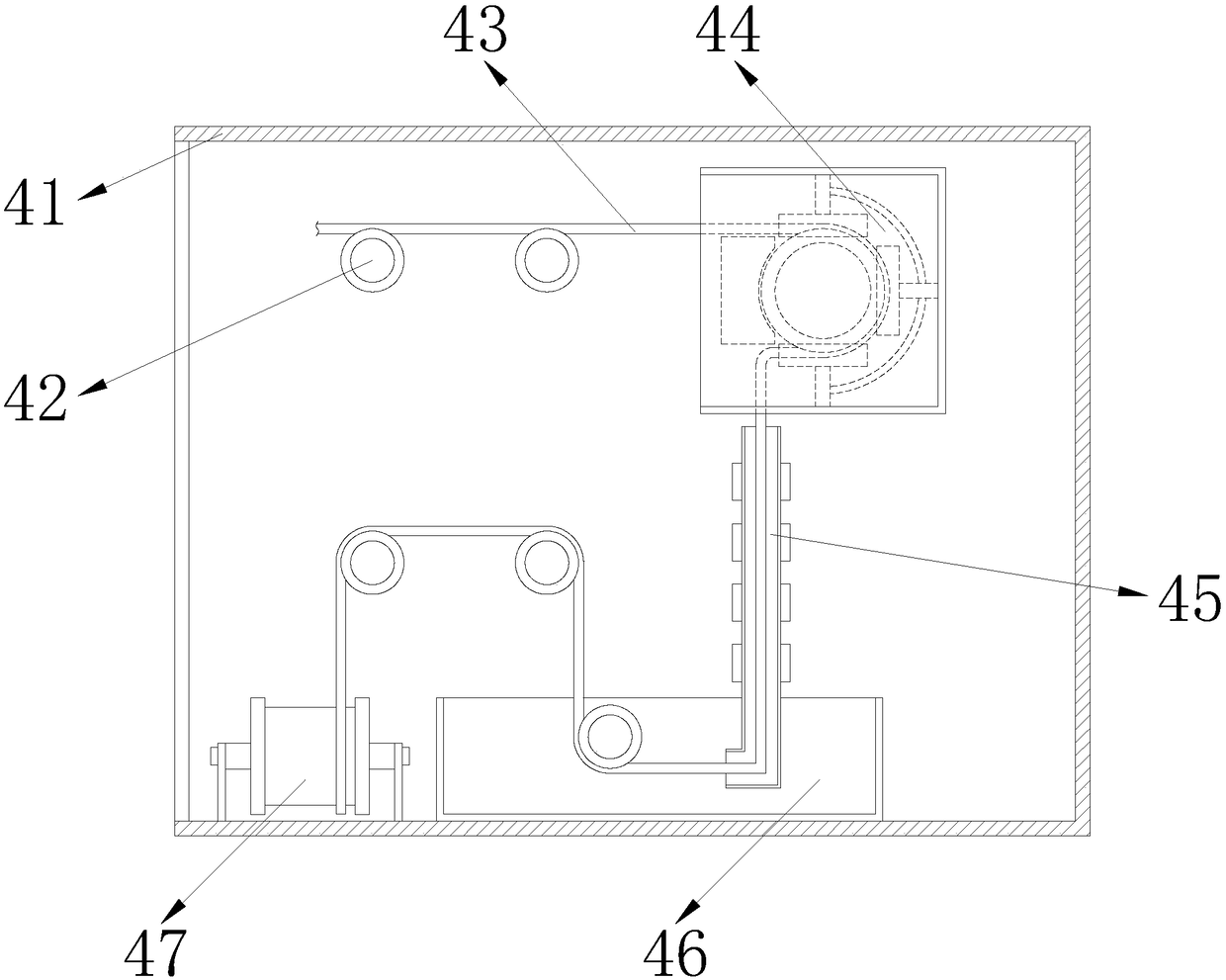

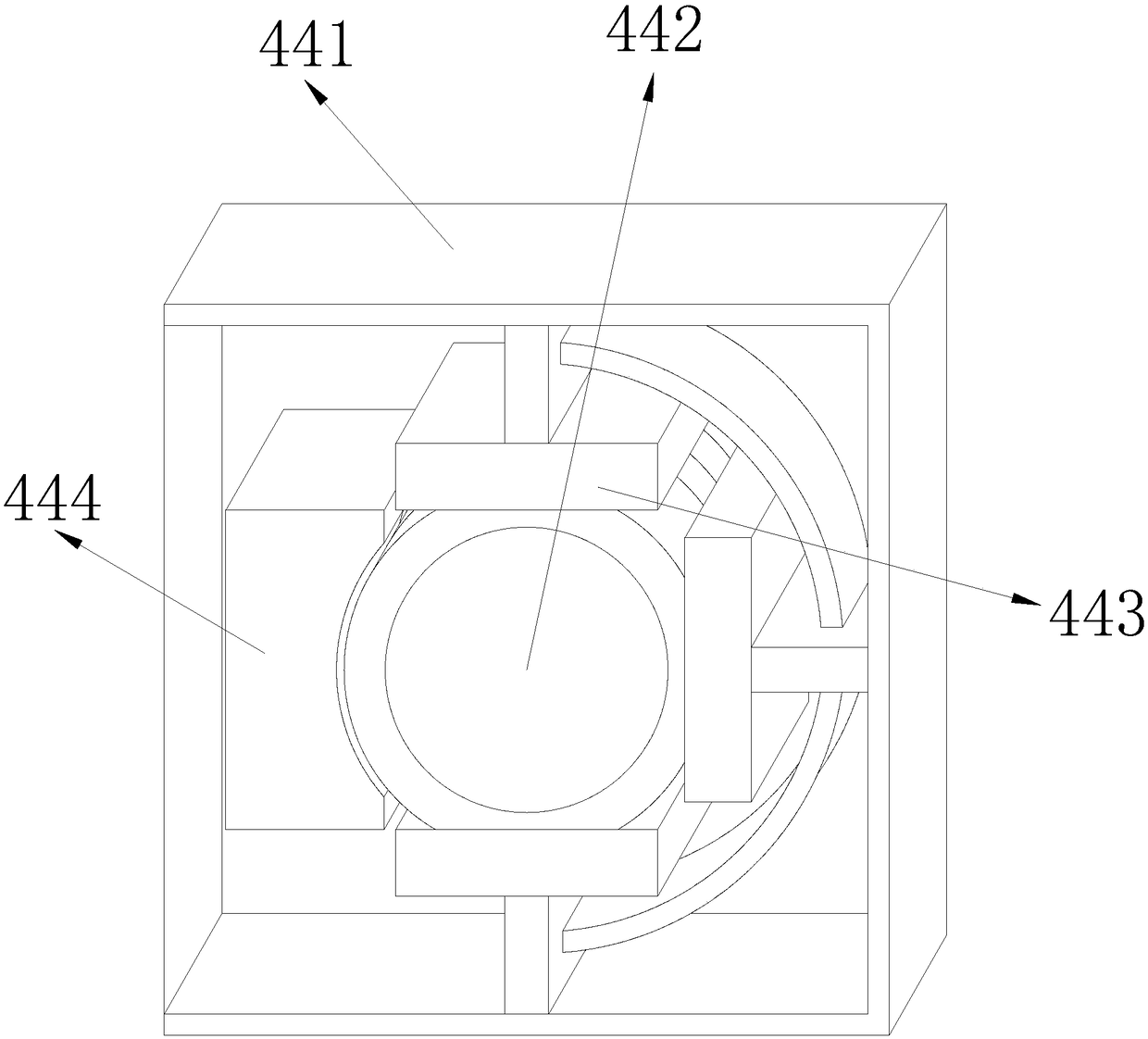

[0020] see Figure 1-Figure 7 , the present invention is an annealing device for anti-ignition and resistance resistance for power cables. Disk 2, the top seat 3 is fixedly installed on the top of the reinforced base 1, the pay-off disk 2 is located at the left end of the contact brush annealing machine 4, and the bottom end of the contact brush annealing machine 4 is fixedly installed on the reinforced base 1, so The top of the contact brush annealing machine 4 is fixedly connected with the top seat 3, and the contact brush annealing machine 4 includes a protective shell 41, a transmission wheel set 42, a cable 43, an electrode wheel mechanism for eliminating ignition 44, an annealing pipe 45, and a cooling box 46. The take-up reel 47, the inside of the protective shell 41 is provided with a drive wheel set 42, the drive wheel set 42 is connected to the cable 43, the cable 43 is connected to the pay-off reel 2, and the ignition electrode is eliminated The wheel mechanism 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com