Vacuum continuous coating system for strip material and transition cabin unit used by same

A technology of vacuum coating and transition chamber, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., to achieve the effect of meeting continuous coating production, reducing the scope and difficulty of vacuuming, and reducing the complexity of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

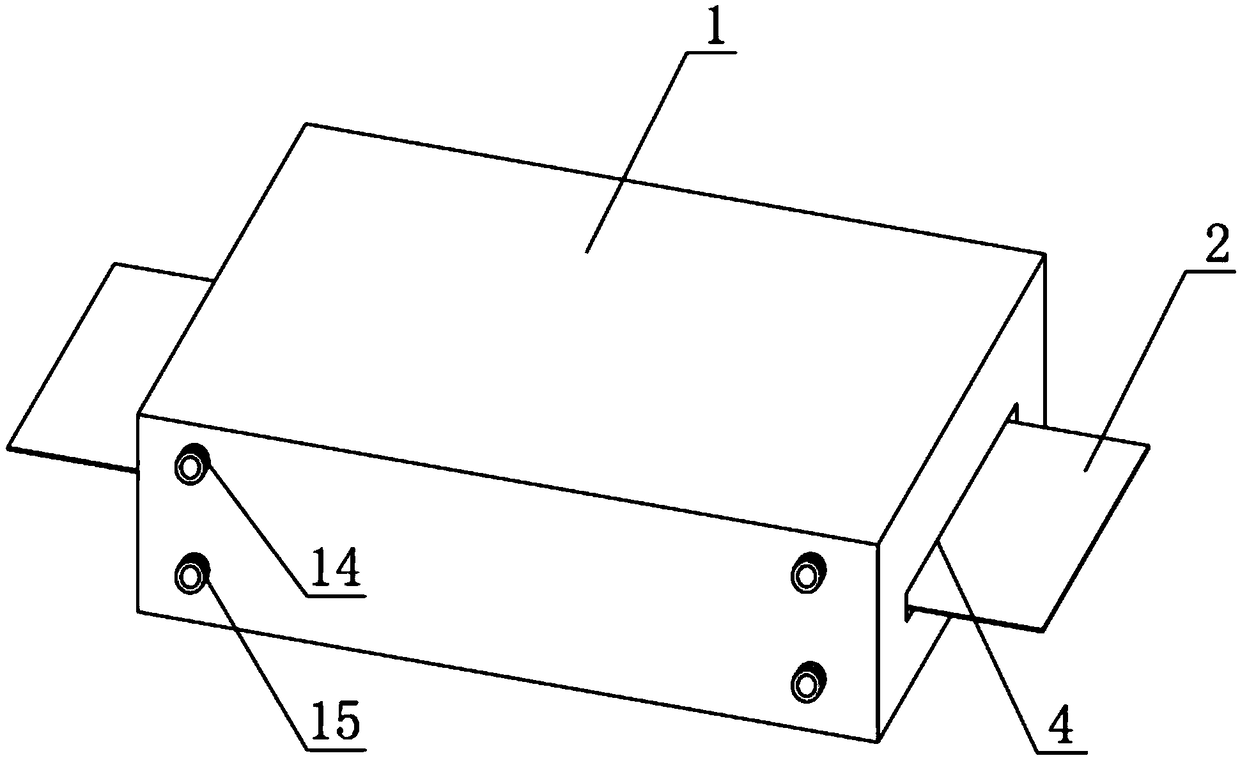

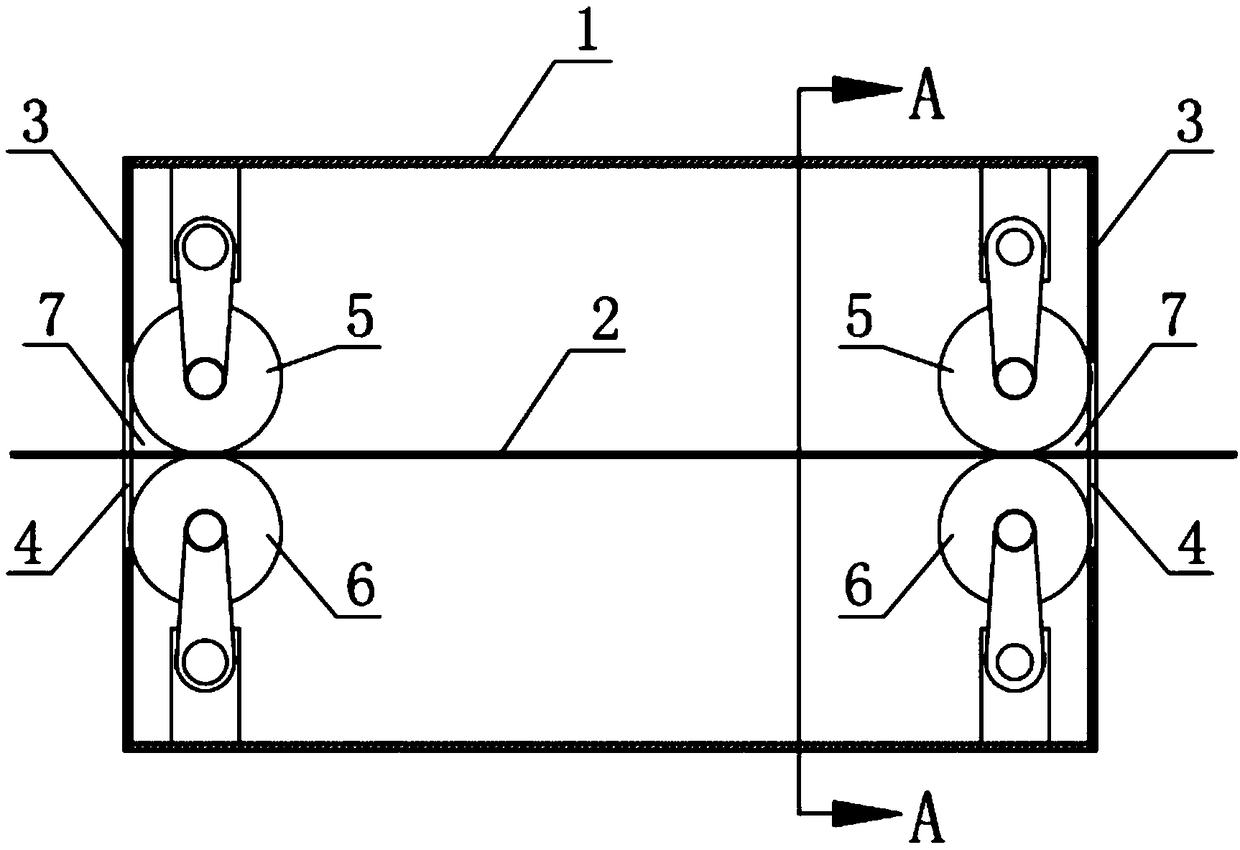

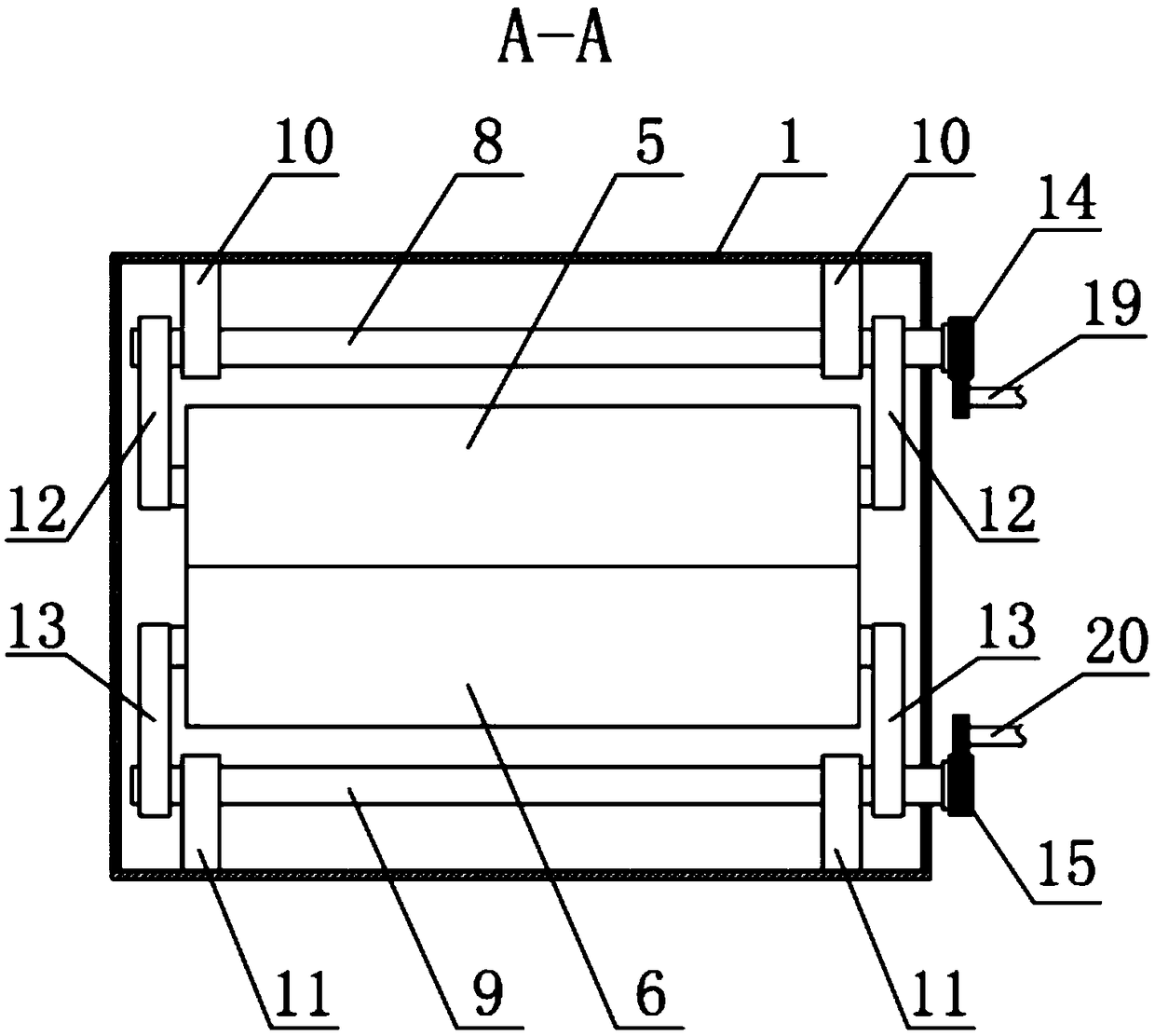

[0038] like Figure 1 to Figure 14As shown in the present invention, the transition cabin unit for strip vacuum continuous coating includes a cabin body 1 with two open ends enclosed by surrounding wall plates, and the two ends of the cabin body 1 are respectively For the feeding port and the discharging port of the strip 2, at least one partition plate 3 is arranged in the cabin 1, and a strip-shaped through hole 4 that allows the strip material 2 to pass through is opened through the partition plate 3; At least one side of the plate 3 is provided with a set of sealing mechanisms. The sealing mechanism includes an upper sealing roller 5, a lower sealing roller 6 and an end sealing plate 7. The upper sealing roller 5 and the lower sealing roller 6 are mirror-symmetrically arranged on the strip. 2 on both sides of the conveying track, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com