Technological method for removing plasma spraying NiAl coatings

A process method and plasma technology, applied in the field of ion sprayed NiAl coating, can solve the problems of difficult processing, large stress deformation, low removal efficiency, etc., and achieve the effect of no change in bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of NiAl coating removal method for aero-engine is carried out according to the following steps:

[0026] (1) Degreasing and water washing: use organic solvents to degrease, after there is no oil, rinse and dry for insulation protection;

[0027] (2) Insulation protection: Use AC850 glue to insulate and protect the surface of the uncoated part;

[0028] (3) chemical removal: prepare the chemical removal tank solution, add water in the solution, then add nitric acid of the same volume successively, then add 5ml / l additive;

[0029] (4) Clean up surface attachments: Take out the sample every few minutes, remove surface attachments with a brush, and continue to react on the coating surface. stop;

[0030] (5) Repeat process 3;

[0031] (6) Washing to remove insulation: remove surface insulation, then rinse and dry with compressed air.

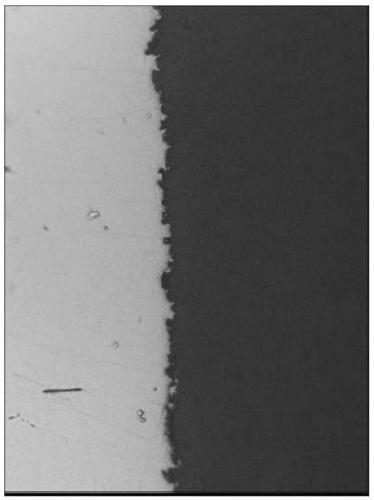

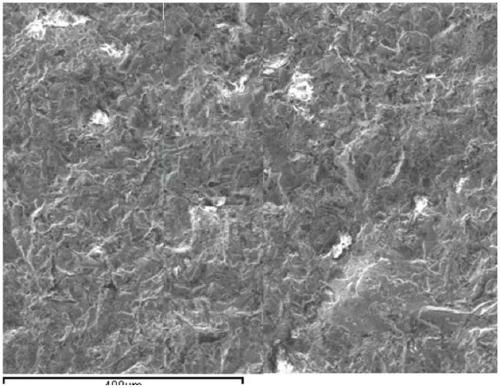

[0032] After blasting the surface of the sample, the NiAl coating was sprayed again, and the coating was removed again with a ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com