Patents

Literature

70results about How to "No obvious corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Additive for strengthening wet flue gas desulfurization technology

InactiveCN102580514AImprove qualityAchieve reuseCalcium/strontium/barium sulfatesDispersed particle separationOrganic acidAdipic acid

The invention belongs to the technical field of a limestone / gypsum wet flue gas desulfurization technology, and particularly relates to an additive for strengthening a wet flue gas desulfurization technology, which comprises the following components in percentage by mass: 35-45% of mixed organic acid, 5-10% of organic acid salt, 6-9% of surfactant, 1-6% of heavy metal salt and 35-45% of dirt dispersion agent; and the mixed organic acid comprises adipic acid, wherein the percentage of mass of the adipic acid in the mixed organic acid is not less than 50%. The additive can be added and used for strengthening the wet flue gas desulfurization technology, improve the desulfurization efficiency of a system, reduce the energy consumption, strengthen oxidization, improve the limestone quality and restrain system scaling, and accordingly, the purposes of energy conservation, consumption reduction and waste recycling are realized.

Owner:SCI GREEN SHANDONG ENVIRONMENT TECH CO LTD

Magnesium and magnesium alloy surface silver-plating method

The invention discloses a magnesium and magnesium alloy surface silver-plating method, and relates to the technical field of magnesium alloy silver plating. According to the method, eight steps including shot blasting, oil removal, excitation, residual film removal, zinc immersion, copper plating, silver plating in advance and silver plating are adopted, good silver plating layers are obtained after magnesium and magnesium alloy surfaces are specially treated, according to magnesium and magnesium alloy silver pieces processed through operation of the process, the silver plating layer bonding force is checked by thermal shock tests, the plating layers are free of peeling, blistering and falling, parts obtained after thermal shocks are subject to bonding force tests according to a QJ479-90 marking method, and the plating layers are free of peeling, blistering and falling. Through trials and errors, all silver plating layers are good in bonding force and free of peeling, blistering and falling; through an QJ458-88 anti-sulphur test, the silver plating layers are not subject to aftertreatment, the anti-sulphur performance is larger than 1 min, and the anti-sulphur performance of partssubject to aftertreatment after silver plating is larger than 5 min. The electroplating magnesium and magnesium alloy silver-plating parts are good in bonding force, high in anti-sulphur performance and resistant to corrosion, the plating layers are free of peeling, blistering and falling, and the method is worthy of application and popularization on industry.

Owner:贵州航天风华精密设备有限公司

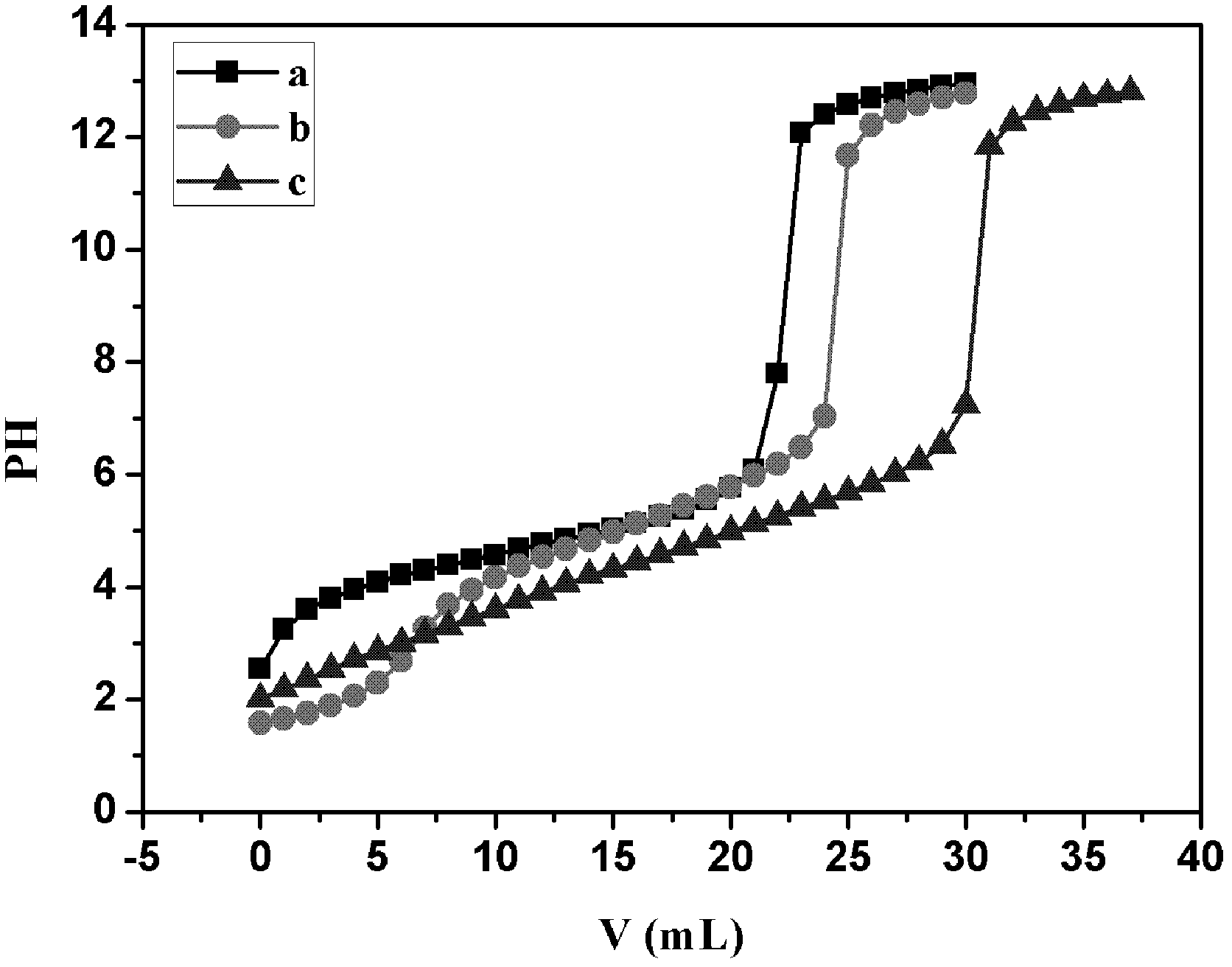

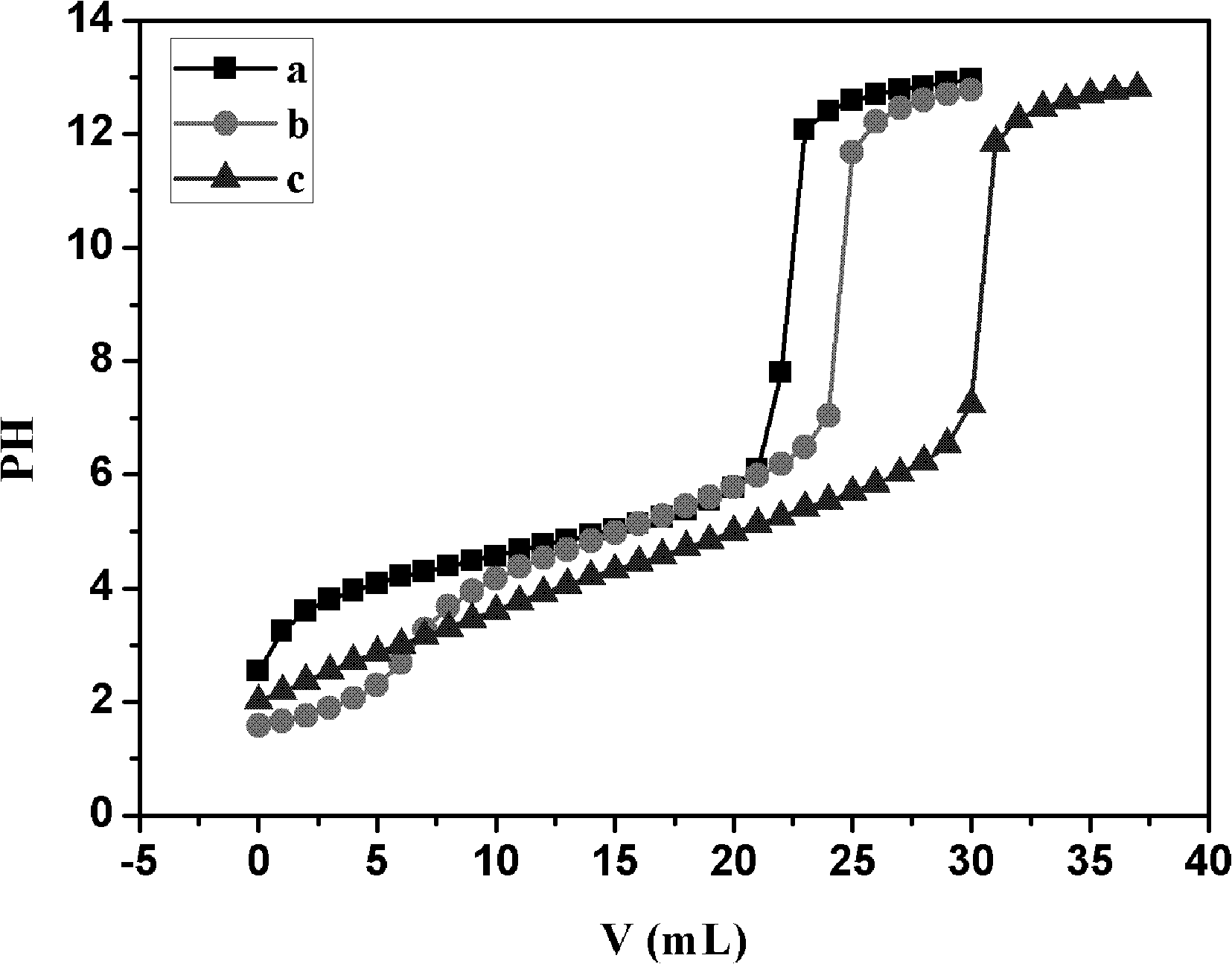

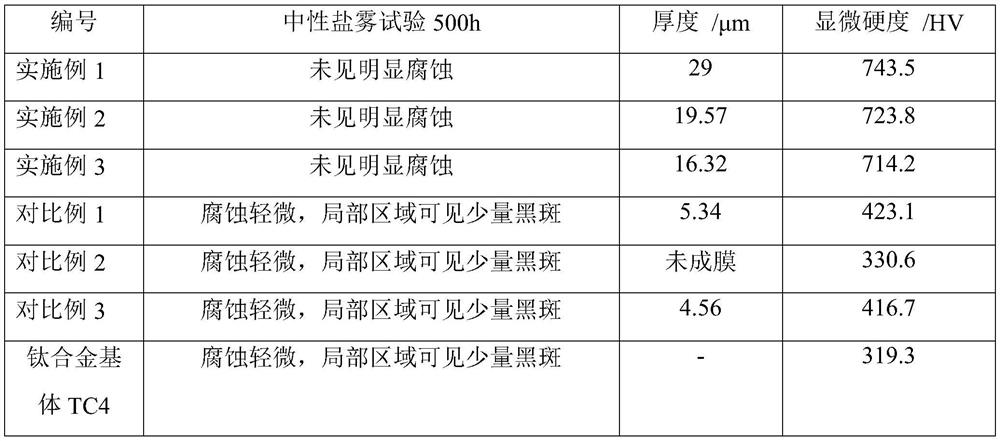

Preparation method of corrosion-resistant titanium alloy micro-arc oxidation coating

InactiveCN112663111AIncrease speedGuaranteed thicknessSurface reaction electrolytic coatingElectrolytic agentMicro arc oxidation

The invention belongs to the technical field of iron and steel smelting, and particularly relates to a preparation method of a corrosion-resistant titanium alloy micro-arc oxidation coating. Aiming at the problems that toxic substances need to be used, the environment is not protected and the process is complex when the corrosion-resistant titanium alloy micro-arc oxidation coating is prepared in the prior art, the invention provides the preparation method of the corrosion-resistant titanium alloy micro-arc oxidation coating. The preparation method comprises the following steps of: a, polishing and grinding titanium alloy for later use; b, preparing an electrolyte; c, putting the titanium alloy serving as an anode into the electrolyte; under the conditions that the voltage is 400-450V, the frequency is 400-500Hz and the duty ratio is 20-40%, introducing anode current into a titanium alloy sample, treating for 5-20 minutes, forming a stable micro-arc on the surface of the titanium alloy sample, and thus obtaining the micro-arc oxidation coating. The electrolyte is safe and environmentally friendly, the operation is easy, and the obtained oxidation coating is high in thickness, large in hardness and excellent in performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

High-temperature-corrosion-resistant paint, preparation method thereof, high-temperature-corrosion-resistant coating and preparation method thereof

ActiveCN107236331AReduce decompositionImprove compactnessFireproof paintsLiquid surface applicatorsTitanium metalDecomposition

The invention provides high-temperature-corrosion-resistant paint, a preparation method thereof, a high-temperature-corrosion-resistant coating and a preparation method thereof. The high-temperature-corrosion-resistant paint comprises chromium, nickel and metal ceramic powder, the metal ceramic powder is ceramic powder with the surface coated with aluminum and / or titanium metal powder, and the ceramic powder comprises Cr3C2 and CeO2. The preparation method of the paint includes: mixing the ceramic powder comprising Cr3C2 and CeO2 with metal comprising titanium and aluminum, performing high-energy ball milling to obtain the metal ceramic powder, and then mixing the metal ceramic powder with chromium and nickel to obtain the high-temperature-corrosion-resistant paint. The preparation method of the paint includes: spraying the paint to the surface of a substrate at supersonic speed to obtain the coating. High-energy ball milling is adopted to realize coating of ceramic by metal, so that decomposition of Cr3C2 in the process of thermal spraying is reduced effectively; titanium and aluminum are low in melting point and are wrapped on the surfaces of Cr3C2 and CeO2, so that improving of compactness of the coating is facilitated; Cr3C2 and CeO2 are hard in texture, so that improving of smoke washout resistance of the coating is facilitated.

Owner:国家能源集团科学技术研究院有限公司武汉分公司 +3

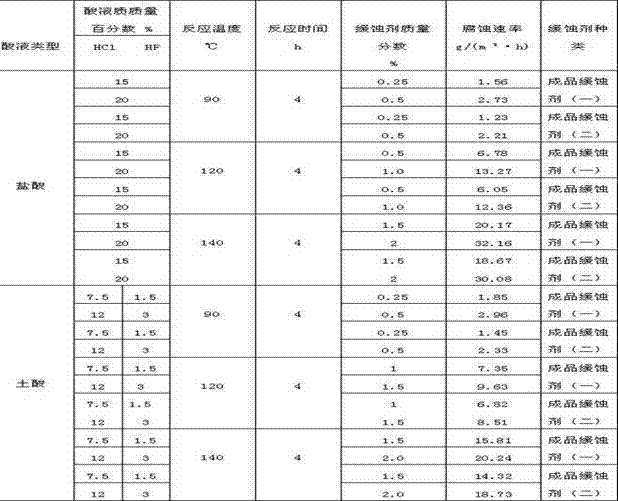

High-temperature acidizing corrosion inhibitor as well as preparation method and application thereof

InactiveCN107987822ANo emissionsNo obvious corrosionDrilling compositionBorehole/well accessoriesSolubilityHeterocyclic amine

The invention relates to a high-temperature acidizing corrosion inhibitor as well as a preparation method and application thereof. The high-temperature acidizing corrosion inhibitor contains the following raw material components in parts by weight: 30-55 parts of methanol, 15-20 parts of acetone, 10-15 parts of formaldehyde, 5-14 parts of heterocyclic amine, 5-10 parts of hydrochloric acid and 10-15 parts of a compounding agent propargyl alcohol. The preparation method for preparing the high-temperature acidizing corrosion inhibitor by virtue of a reaction kettle comprises the steps of preparing a parent corrosion inhibitor, a preparing a finished corrosion inhibitor, and detecting the finished corrosion inhibitor. The corrosion inhibitor is suitable for being used in well fracturing acidizing processes of 15%-20% hydrochloric acid and mud acid at 90-140 DEG C. A synthetic method is simple, no pollutant is discharged, the corrosion inhibitor is used in the well fracturing acidizing processes of hydrochloric acid and mud acid and has the advantages of good solubleness, low dosage and excellent corrosion inhibition performance; and an equipment pipeline is not obviously corroded, sothat the service life of equipment is prolonged.

Owner:唐山市金沙工贸有限公司

Preparation method of neodymium-iron-boron magnet applicable to new energy automobile

InactiveCN106782976AImprove performanceNo obvious corrosionInductances/transformers/magnets manufactureMagnetic materialsNew energyNiobium

The invention relates to the field of magnetic steel production, and particularly relates to a preparation method of neodymium-iron-boron magnet applicable to new energy automobiles. The method comprises the steps that raw materials of 28.25% of praseodymium neodymium metals, 2.75% of dysprosium, 0.98% of boron, 0.3% of niobium, 0.6% of aluminum, 2% of cobalt, 0.2% of copper, 0.25% of terbium, 0.2% of gallium, and 64.47% of pure iron are weighed according to the weight proportions and are mixed evenly, and after the processes of fusion in a vacuum induction swing furnace, copper wheel cooling, reaction in a hydrogen quenching reactor, oxidizing agent adding, stirring, and grinding, the magnetic powder is obtained; then models are made for the magnetic powder according to the sizes of the products, and in an environment of complete seal and low oxygen, after the pressing with a high magnetic field pressing machine, and under a high intensity pressure of 20 Mpa, crude products with densities of 4.4-4.8 g / cm<3> are made; the crude products are put into a vacuum sintering furnace, under a vacuum condition, the crude products are heat preserved under a high temperature of 1020-1045 DEG C for 5 hours and under an intermediate temperature of 850-950 DEG C for 3 hours and under a low temperature of 500-560 DEG C for 5 hours, and the neodymium-iron-boron magnet products are obtained.

Owner:ZHEJIANG ZHONGKE MAGNETIC IND

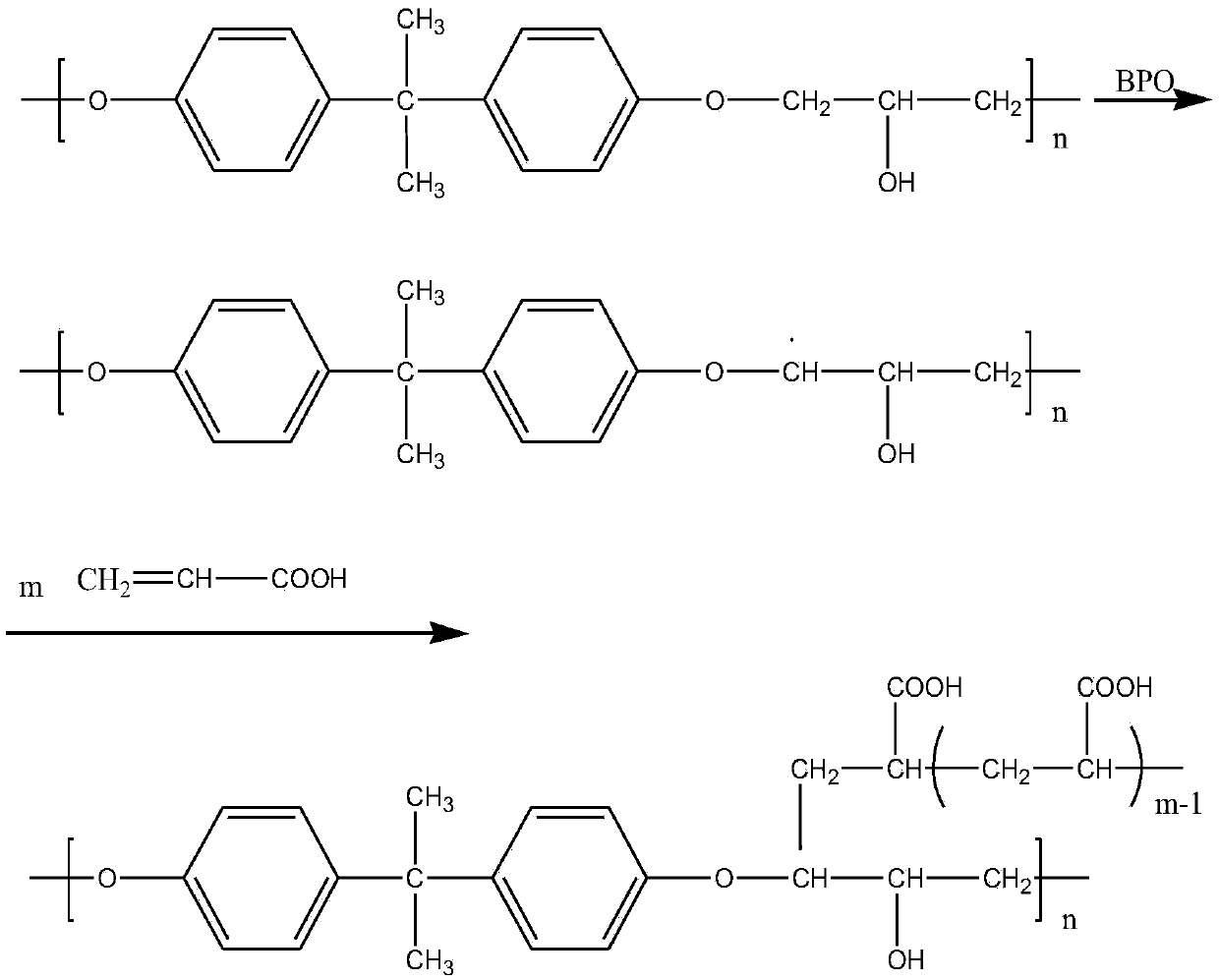

Anticorrosive paint composition containing self-emulsifying curing agent and preparation method of anticorrosive paint

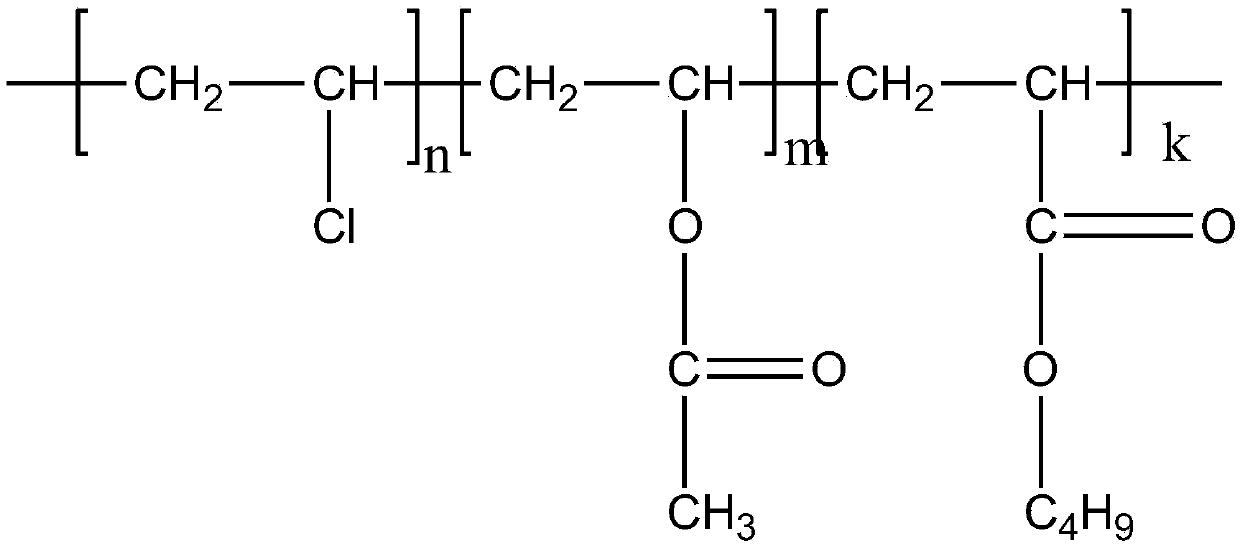

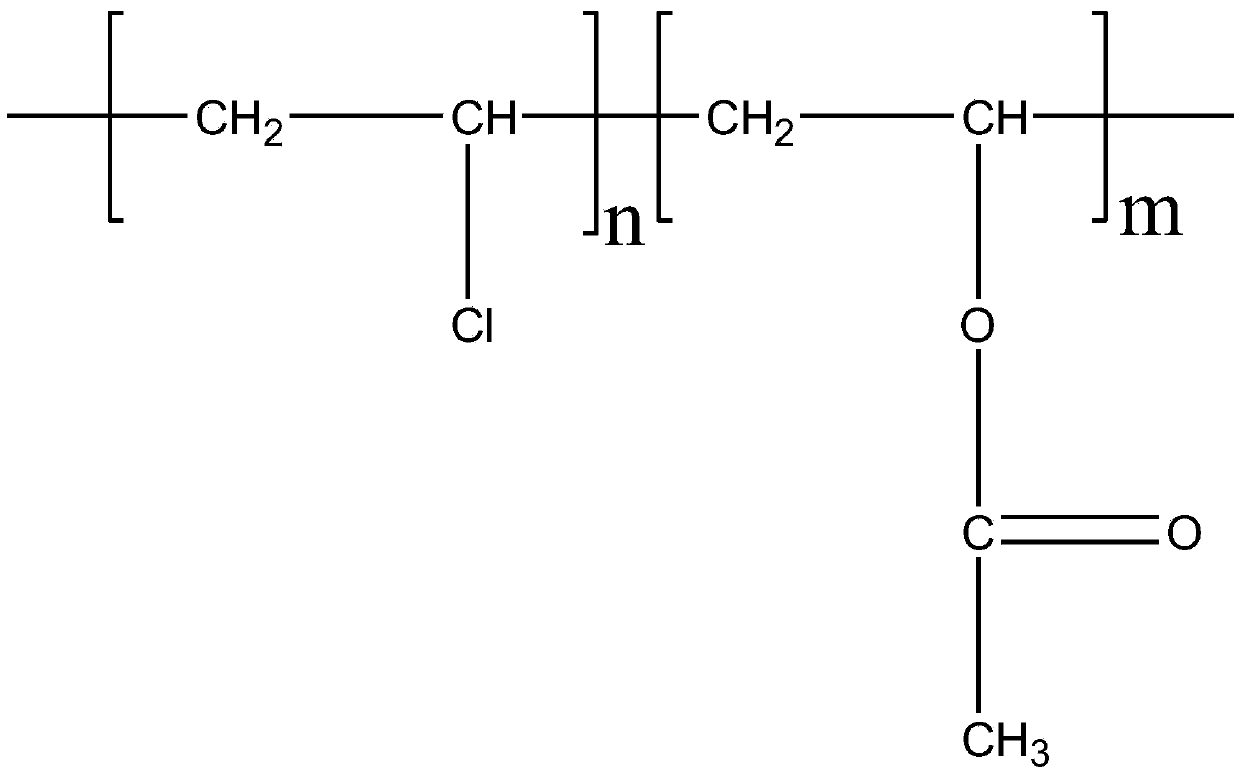

ActiveCN105368241ANo obvious corrosionOrganic compound preparationCarboxylic acid amides preparationWater basedEpoxy

The invention discloses an anticorrosive paint composition containing a self-emulsifying curing agent. The anticorrosive paint composition is prepared from a component A and a component B according to the mass ratio that A:B=(5-10):1. The component A is prepared from, by mass, 5% to 15% of water-based epoxy ester resin, 10% to 30% of chloroethylene-vinyl acetate-butyl acrylate resin, 10% to 15% of chloroethylene-vinyl acetate resin, 15% to 20% of mica, 15% to 20% of talcum powder, 5% to 8% of antifoaming agent, 9% to 12% of emulgator and 10% to 15% of deionized water. The component B is prepared from, by mass, 5% to 16% of self-emulsifying curing agent, 15% to 20% of triethylene diamine, 15% to 20% of diethylenetriamine, 10% to 15% of sodium nitrite, 25% to 32% of zinc phosphate and 10% to 20% of deionized water. The paint has the advantages that good abrasion resistance and corrosion resistance are achieved, the raw materials are easy to obtain, and price is low. The invention further discloses a preparation of the anticorrosive paint composition containing the self-emulsifying curing agent.

Owner:烟台鲁迈防水防腐材料有限公司

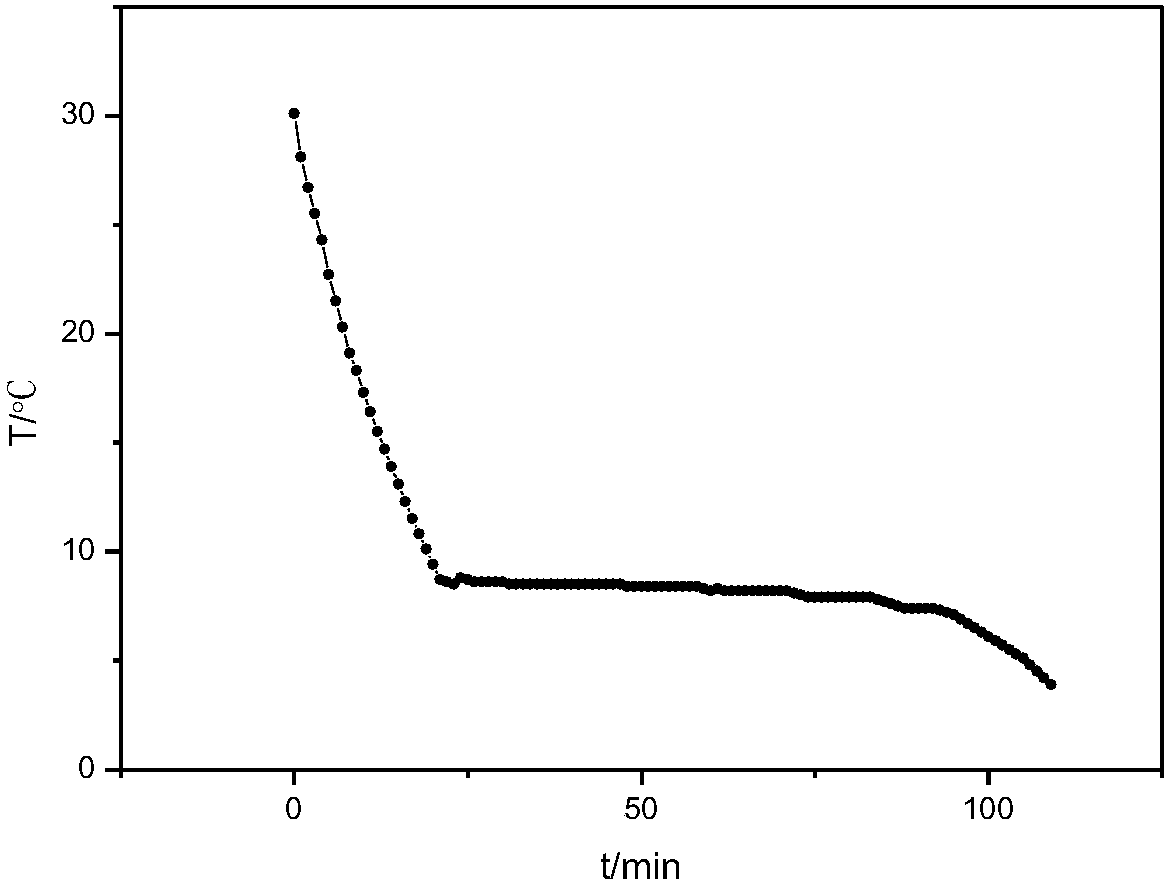

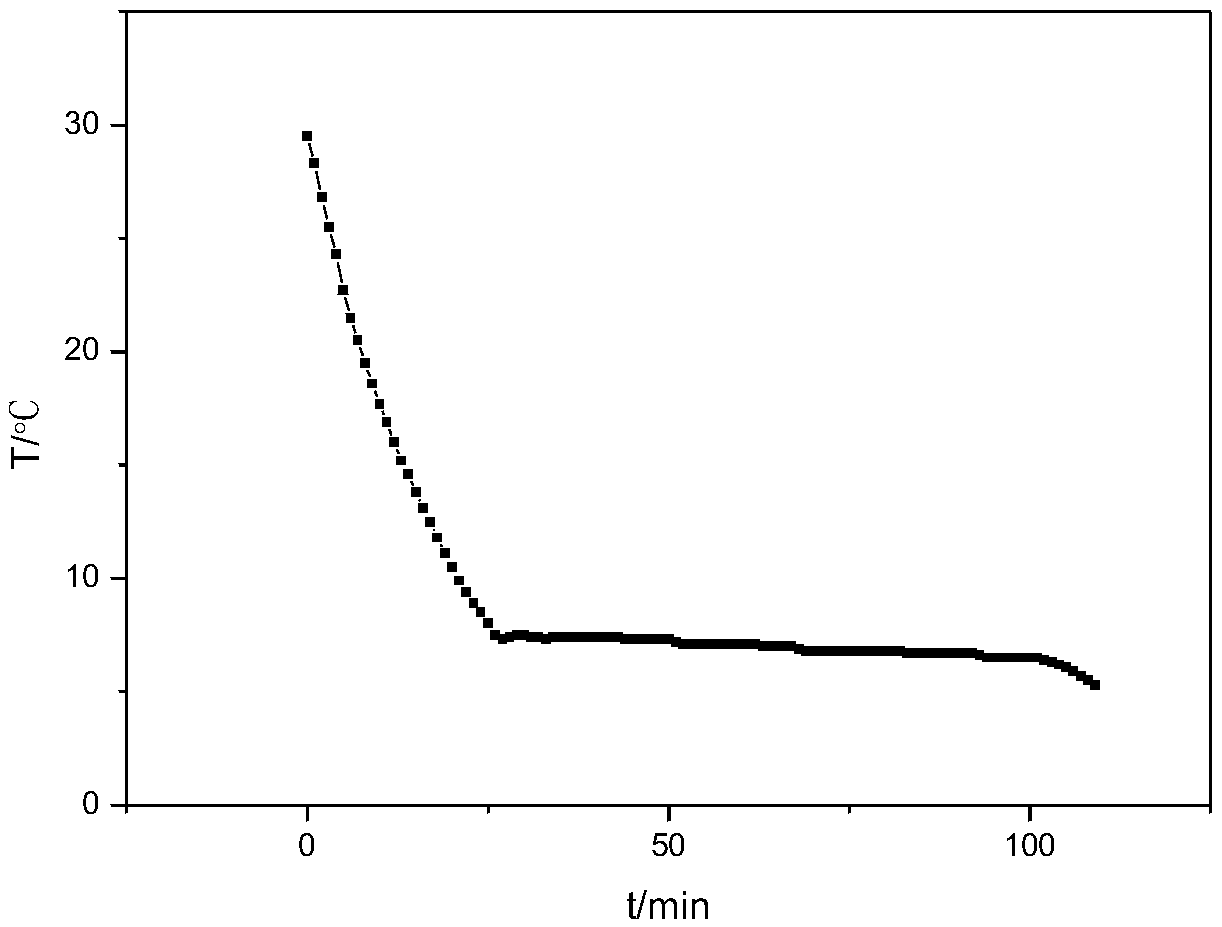

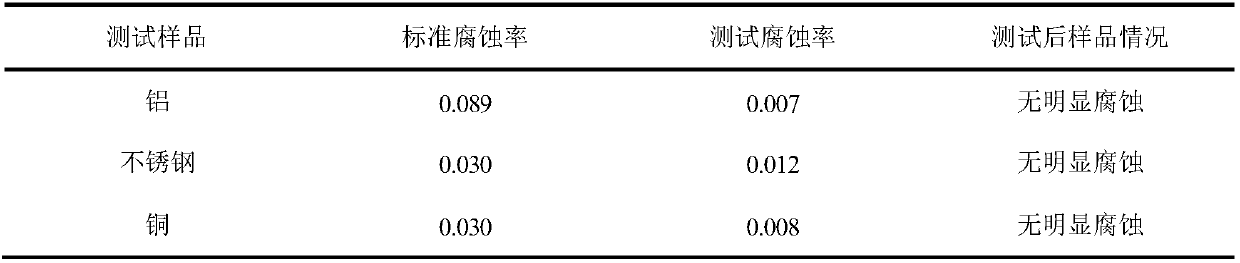

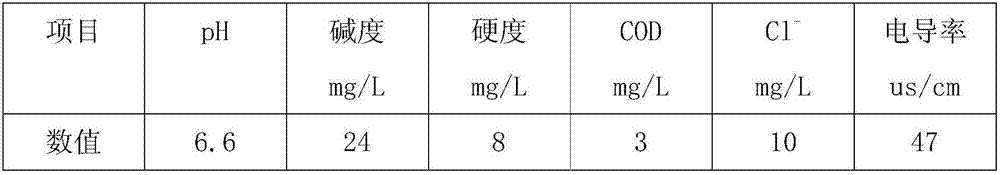

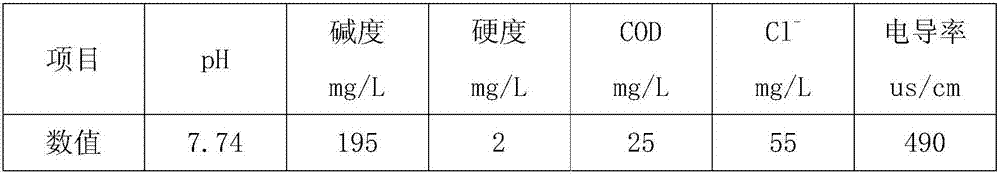

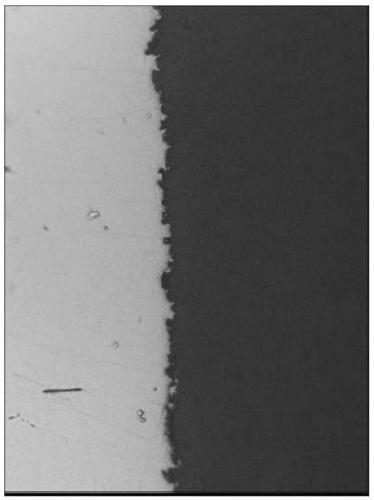

Inorganic phase-change material used for air conditioner cold accumulation and preparation method thereof

The invention discloses an inorganic phase-change material used for air conditioner cold accumulation. The inorganic phase-change material comprises the following components in parts by weight: 75 to80 parts of sodium sulfate decahydrate, 7 to 10 parts of ammonium chloride, 2 to 4 parts of borax, 5 to 8 parts of hydrophilic fumed silica, 2 to 4 parts of a pH conditioning agent and 0.1 to 0.5 partof conductive particles. The preparation method comprises the following steps: (1) adding sodium sulfate decahydrate and ammonium chloride into a mixer, simultaneously heating and stirring, warming and heating to 40 to 50 DEG C; (2) adding the pH conditioning agent and borax, and stirring at a constant temperature until borax is completely dissolved; and (3) adding hydrophilic fumed silica into the mixer, stirring at the constant temperature and low speed, then adding the conductive particles, and then stirring at high speed to prepare the phase-change material. The phase-change temperature of the inorganic phase-change material used for air conditioner cold accumulation is 7 to 9 DEG C, the phase-change latent heat of the inorganic phase-change material used for air conditioner cold accumulation is 135 to 198 J / g, and the inorganic phase-change material is free of obvious corrosion to aluminum, stainless steel and copper respectively.

Owner:JIANGSU UNIV OF TECH

Corrosion inhibitor for closed soft water circulating cooling water system and application

ActiveCN107162225APhosphate-free and environmentally friendlyEfficient corrosion inhibitionScale removal and water softeningSoft waterBenzotriazole

The invention discloses a corrosion inhibitor for a closed soft water circulating cooling water system and an application. Anti-corrosion protection is carried out on thermal equipment, so that the service life of system equipment in a closed soft water circulating cooling water environment is effectively prolonged. The corrosion inhibitor has the characteristics of being efficient, phosphorus-free and environment-friendly. The corrosion inhibitor is characterized by comprising a steel corrosion inhibitor and a copper corrosion inhibitor, wherein the steel corrosion inhibitor comprises triethanolamine borate, ascorbic acid and urotropine; and the copper corrosion inhibitor comprises benzotriazole.

Owner:北京拓凯化工技术有限公司

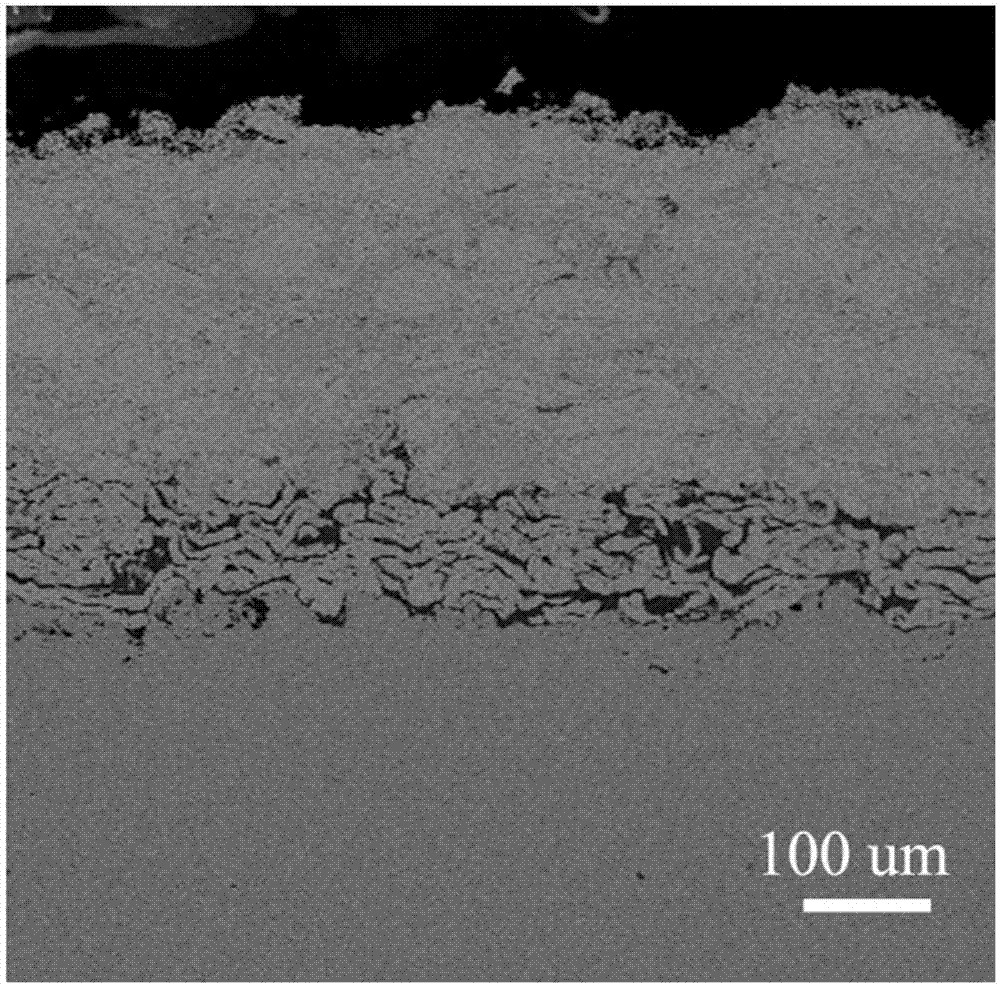

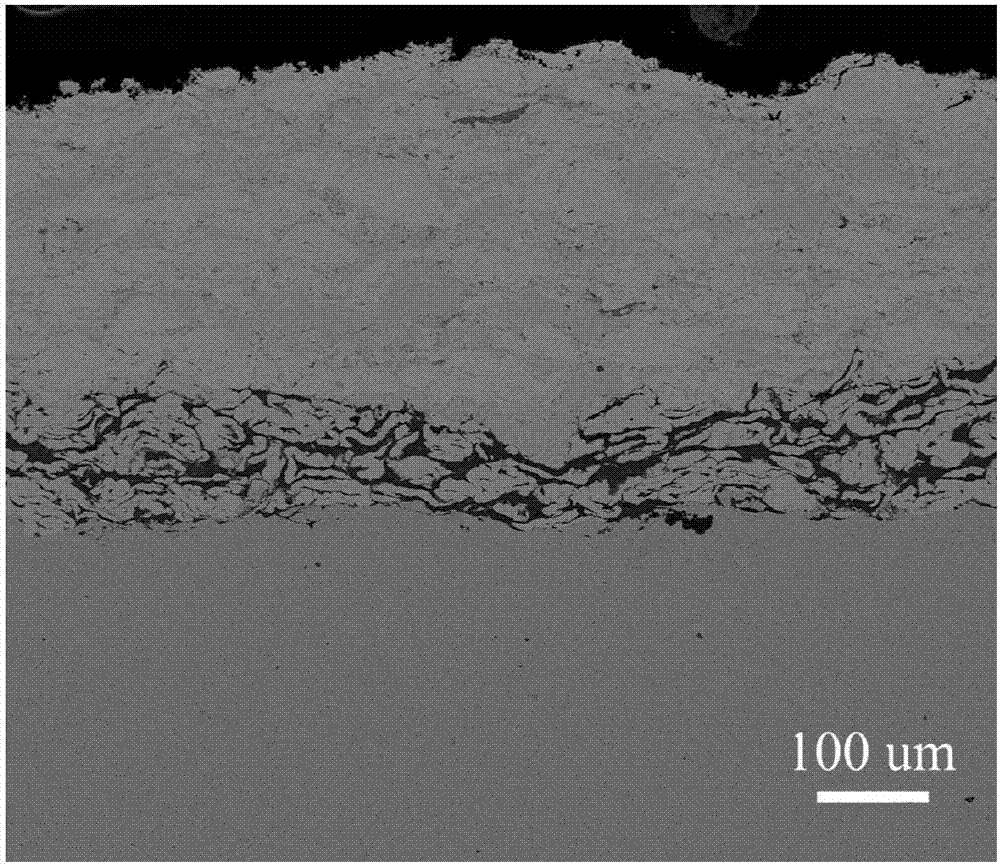

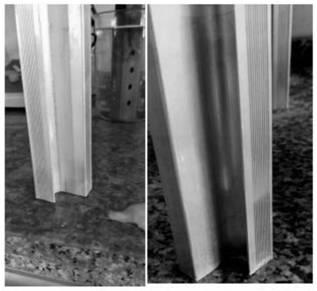

Technological method for removing plasma spraying NiAl coatings

The invention belongs to the field of surface treatment, and particularly relates to a technological method for removing plasma spraying NiAl coatings for GH4169 materials. The plasma spraying NiAl coatings are removed through oil removal and water washing, insulation protection, chemical removal, cleaning of surface attachments, chemical removal and insulator removal through water washing. With the method, the problem of scraping of parts due to the fact that coating of the parts coated with NiAl coatings cannot be removed at present is solved, the manufacturing cost of parts of engines is greatly reduced, the coatings are removed with the chemical method, the service life of the parts is prolonged, meanwhile, compared with the mechanical method for removing the coatings, the method has the advantages that the tool fixture cost is reduced, the production cycle is shortened, and the method has the very high economic value.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Corrosion-resistant palladium alloy for yellow jewelry and processing technology thereof

The invention discloses a corrosion-resistant palladium alloy for a yellow jewelry and a processing technology thereof. The corrosion-resistant palladium alloy comprises, 0.5-0.8 wt.% of Te, 1.0-1.5 wt.% of Ca, 1.4-1.8 wt.% of V, 1.4-1.6 wt.% of W, 0.2-0.3 Wt.% of C, 2.0-2.8 wt.% of Ru, 1.0-1.2 wt.% of Y, 25.0-28.0 wt.% of Sn, and the balance palladium. The invention provides the palladium alloy which is not available in the market and has excellent performance, and the types of the palladium alloy for jewelry on the market are greatly enriched.

Owner:GUANGZHOU YUZHI TECH CO LTD

18K corrosion-resistant brittle-fracture-resistant gold alloy with spangle effect and process thereof

InactiveCN110106385ALow tendency to shrinkSmall hole ratioFoundry mouldsFoundry coresGold jewelryBrittle fracture

The invention discloses an 18K corrosion-resistant brittle-fracture-resistant gold alloy with a spangle effect and a process thereof. The 18K corrosion-resistant brittle-fracture-resistant gold alloywith the spangle effect comprises the following components of, by weight, 0.5%-0.8% of In, 0.1%-0.3% of Nb, 1.0%-2.0% of Sc, 0.2%-0.5% of Ni, 2.0%-2.5% of Hf, 0.1%-0.2% of Sn, 0.4%-0.8% of Sb, 74.0%-76.0% of Au and the balance silver. According to the 18K corrosion-resistant brittle-fracture-resistant gold alloy, the gold alloy with the spangle effect is provided for the gold alloy for jewelry, namely, the surface of the gold jewelry prepared by adopting the material can be pearly colorful; and due to the fact that the surface impression of the jewelry is superior and the smelting and processing technology is simple, the material meets the urgent need of the domestic and foreign market and also can obtain great economic value at the same time after being used in the jewelry industry.

Owner:杭州辰卓科技有限公司

High-carbon steel surface corrosion resistant non-spangle type hot dipping Y containing zinc alloy

InactiveCN108411236AExcellent volatility resistanceImprove oxidation resistanceHot-dipping/immersion processesHigh carbonZinc alloys

The invention discloses a high-carbon steel surface corrosion resistant non-spangle type hot dipping Y containing zinc alloy and a machining technology thereof. The alloy is prepared from the ingredients, in percentage by weight: 0.8-1.0% of Li, 0.2-0.5% of Y, 1.0-2.0% of Si, 1.0-1.5% of In, 0.2-0.3% of Sc, 0.1-0.2% of Er and the balance of zinc. The development of the alloy can solve the phenomenon that spangles occur on the surface of a plating piece in the industrial hot dipping galvanizing process. The alloy has the characteristics of being low in production cost and convenient for scale production.

Owner:GUANGZHOU YUZHI TECH CO LTD

Magnesium-aluminum alloy paint remover and preparation method thereof

InactiveCN105295511AImprove removal efficiencySolve surface corrosionChemical paints/ink removersBromine1-bromohexadecane

The invention provides a magnesium-aluminum alloy paint remover. The magnesium-aluminum alloy paint remover comprises, by weight, 60-80 parts of acetone, 8-15 parts of methyl methacrylate, 5-12 parts of polyvinyl alcohol resin, 2-5 parts of sodium palmitate, 4-8 parts of glycerin, 3-7 parts of sodium tripolyphosphate, 2-7 parts of chlorinated paraffin, 1-4 parts of 1-bromohexadecane, 4-9 parts of N-methylimidazole and 2-5 parts of a surfactant. The invention provides a preparation method of the magnesium-aluminum alloy paint remover. The magnesium-aluminum alloy paint remover can effectively remove paint on the surface of a magnesium-aluminum alloy, has high removal efficiency, does not produce obvious corrosion to the magnesium-aluminum alloy base after paint removal treatment and effectively solves problems of corrosion of the surface of the magnesium-aluminum alloy base subjected to paint removal.

Owner:SUZHOU JIEDERUI PRECISION MACHINERY

Palladium alloy for yellow jewelry with large-variable capacity and processing process thereof

The invention discloses a palladium alloy for yellow jewelry with large-variable capacity and a processing process thereof. The palladium alloy consists of the following components in percentage by weight: 0.3-0.8wt% of Ca, 2.4-5.8wt% of Sn, 2.2-3.6wt% of Bi, 0.4-1.2wt% of Mo, 0.2-0.4wt% of C, 4.0-6.5wt% of Pd, 1.0-1.5wt% of Mn, 20.0-25.0wt% of Zn and the balance of palladium. The invention provides the yellow palladium alloy with yellow excellent, which is absent on the market; and moreover, palladium alloy type for jewelry on the market is greatly enriched.

Owner:GUANGZHOU YUZHI TECH CO LTD

Yellow Miao silver alloy with features of low density, light weight and corrosion resistance, and technology thereof

The invention discloses a yellow Miao silver alloy with the features of low density, light weight and corrosion resistance, and a technology thereof. The yellow Miao silver alloy comprises, by weight,0.8%-1.2% of Li, 3.0%-4.0% of Al, 4.0%-6.0% of Mg, 0.4%-0.6% of B, 0.5%-0.8% of Sc, 10.0%-15.0% of Zn, 30.0%-50.0% of Ag and the balance copper. According to the yellow Miao silver alloy, a light-weight selection scheme is provided for Miao silver alloy in China, and the obtained product not only has excellent yellow appearance, but also is extremely resistant to hydrogen sulfide corrosion. The requirements of product update of the jewelry industry and the industry upgrade in China can be promoted through the implementation and industrialization of the yellow Miao silver alloy effectively.

Owner:GUANGZHOU YUZHI TECH CO LTD

Corrosion-resistant cobalt alloy with excellent casting property for surface boat and submarine

The invention discloses a corrosion-resistant cobalt alloy with excellent casting property for a surface boat and a submarine. The alloy consists of the following components in percentage by weight: 1.0-1.5wt% of Ba, 4.0-6.0wt% of In, 1.5-2.0wt% of Ag, 0.4-0.8wt% of W, 2.0-3.0wt% of Bi, 0.4-0.6wt% of V, 2.0-3.4wt% of Ge, 0.2-0.4wt% of Re and the balance of cobalt. The material provides a novel materials science scheme for a corrosion-resistant cobalt alloy used under a marine environment, and also provides the cobalt alloy with excellent casting property. The alloy is implemented and industrialized, so that commercial upgrading needs, on the high-end cobalt alloy material, of the surface boat and submarine field in China are greatly promoted.

Owner:GUANGZHOU YUZHI TECH CO LTD

Adsorbent and preparation method thereof

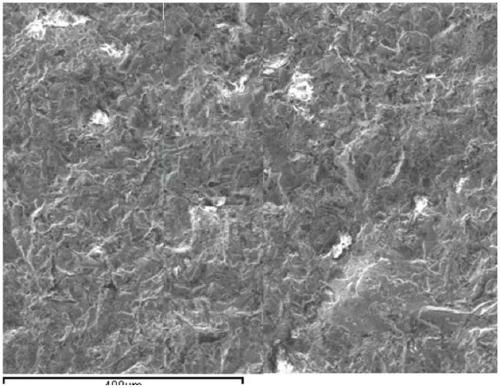

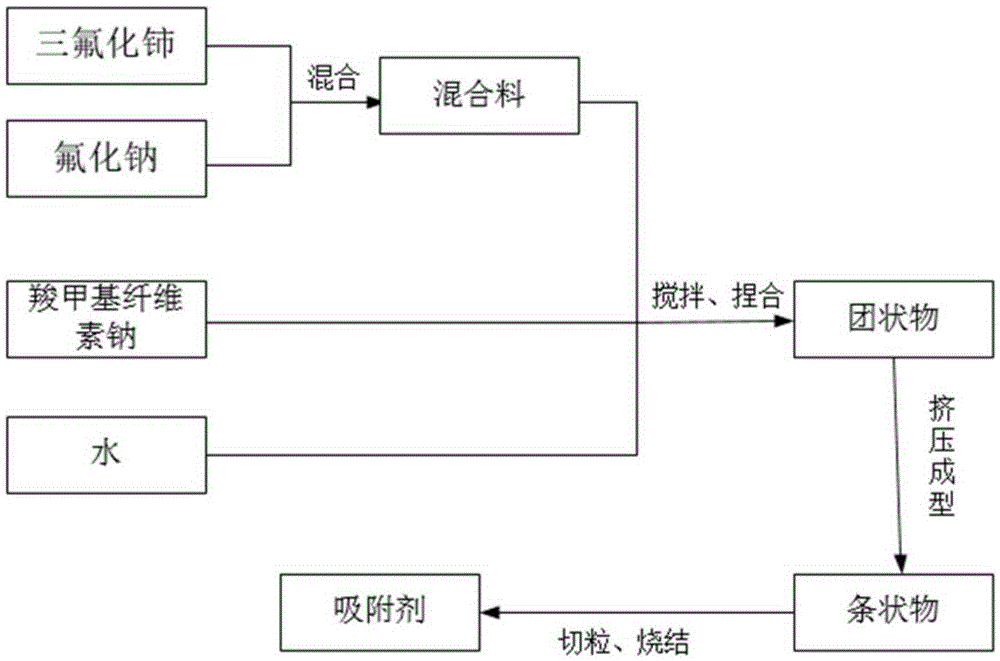

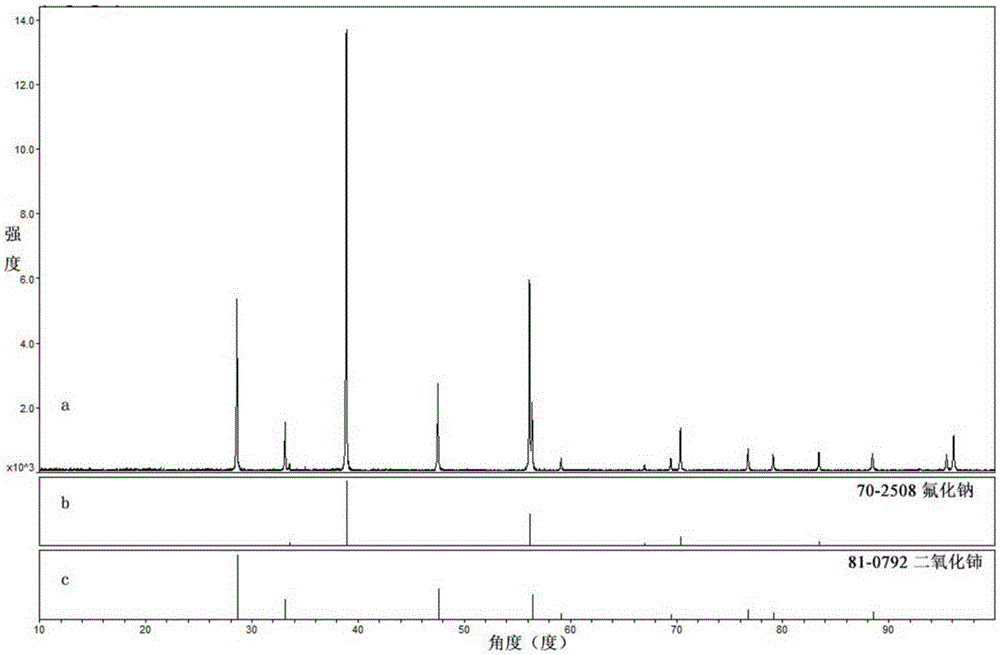

InactiveCN106669587AEasy to prepareNo obvious corrosionOther chemical processesDispersed particle separationSodium fluorideCorrosion

The invention discloses an adsorbent and a preparation method thereof. The adsorbent comprises, by mass, 70 to 99% of sodium fluoride and 1 to 30% of cerium oxide. The adsorbent in the invention has a large specific surface area, the preparation method of the adsorbent is simple, and obvious equipment corrosion during the preparation process is avoided.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

High-strength corrosion-resistant Pb-Li-Si lead-lithium alloy for shielding material

The invention discloses high-strength corrosion-resistant Pb-Li-Si lead-lithium alloy for a shielding material and a processing technology thereof. The alloy comprises the following components of, byweight, 0.4-2.5 wt.% of Li, 1.8-3.6 wt.% of Si, 1.4-2.3 wt.% of Bi, 0.8-1.2 wt.% of Ni, 0.2-0.4 wt.% of Sn, 0.1-0.2 wt.% of La and the balance lead. The lead-lithium alloy has the high strength and the corrosion resistance which are not possessed by the lead alloy used by the traditional shielding material. The alloy and the method can be effectively applied to the fields of nuclear reactors, medical radiation source shielding, nuclear waste treatment and the like; and the production process is simple, the equipment requirement is low, and the large-scale industrial application is faciliated.

Owner:GUANGZHOU YUZHI TECH CO LTD

Wear-resistant nickel-allergy-free 18K platinum material for jewelry and processing technology thereof

The invention discloses a wear-resistant nickel-allergy-free 18K platinum material for jewelry and a processing technology thereof. The alloy comprises following components in percentage by weight: 0.8 to 1.0 wt.% of Ca, 0.2 to 0.4 wt.% of Re, 0.6 to 1.4 wt.% of Fe, 2.0 to 3.0 wt.% of Ge, 8.0 to 10.0 wt.% of In, 10.0 to 12.0 wt.% of Ag, and the balance being gold. The provided K14 platinum does not contain nickel, which is allergic to human body and is usually contained by platinum alloy in the prior art. The provided K14 platinum does not contain any nickel, is friendly to human body, and isdeveloped by optimizing the components. The bottleneck of the jewelry field is broken through effectively. The application and industrialization of the K14 platinum may generate great economic and social benefits.

Owner:GUANGZHOU YUZHI TECH CO LTD

Hot-dipped galvanized aluminum alloy containing Mg and Ca for fishery steel wire under marine environment

InactiveCN108441699AExcellent volatility resistanceImprove oxidation resistanceHot-dipping/immersion processesDip-coatingCorrosion

The invention discloses a hot-dipped galvanized aluminum alloy containing Mg and Ca for a fishery steel wire under the marine environment. The hot-dipped galvanized aluminum alloy comprises the ingredients of, in percentage by weight, 0.3-0.5% of Ca, 2.0-4.0% of Mg, 0.3-0.5% of Ti, 1.0-3.0% of Sn, 30.0-42.0% of Al, 0.5-0.8% of Cr and the balance zinc. The hot-dipped galvanized aluminum alloy for the marine fishery steel wire can be used at the temperature of 420-480 DEG C, and better corrosion resistance is achieved compared with a traditional hot-dipped coating. The hot-dipped galvanized aluminum alloy has great significance to prolonging of the service life of the marine fishery steel wire.

Owner:GUANGZHOU YUZHI TECH CO LTD

Corrosion-resisting Sc containing lead-lithium alloy with extremely low machining hardening rate

The invention discloses a corrosion-resisting Sc containing lead-lithium alloy with an extremely low machining hardening rate and a machining technology of the corrosion-resisting Sc containing lead-lithium alloy. The corrosion-resisting Sc containing lead-lithium alloy comprises components including, by weight percent, 0.8 wt.%-1.5 wt.% of Li, 0.2 wt.%-0.5 wt.% of Sc, 0.2 wt.%-0.4 wt.% of Ni, 0.6wt.%-0.8 wt.% of Cu, 0.5 wt.%-0.6 wt.% of Ta, 0.2 wt.%-0.4 wt.% of Ge, 0.2 wt.%-0.4 wt.% of Eu and the balance lead. The lead-lithium alloy has the extremely low machining hardening rate and excellent corrosion-resisting performance. The performance exceeds a traditional shielding material lead alloy, and the corrosion-resisting Sc containing lead-lithium alloy is widely applied to the military and civil fields.

Owner:GUANGZHOU YUZHI TECH CO LTD

Aluminum-based alloy containing In and Li and having Lima alloy solidification characteristic

The invention discloses an aluminum-based alloy containing In and Li and having a Lima alloy solidification characteristic. The alloy comprises, by weight percentage, 0.5-1.0 wt.% of Li, 2.0-3.0 wt.%of Mg, 4.0-4.5 wt.% of In, 2.0-3.0 wt.% of Bi, 1.0-2.0 wt.% of Ge, 5.0-8.0 wt.% of Sn, 0.2-0.4 wt.% of Th, 1.0-2.0 wt.% of Ag and the balance aluminum. The material provides a lightweight solution scheme of a substitute product for a Lima alloy for bronze statue casting in the Tibetan area in China, that is, a novel aluminum alloy for casting is provided. Implementing and industrializing of the material can effectively promote updating of new materials in the region ornament industry in China and the industry upgrading requirement.

Owner:GUANGZHOU YUZHI TECH CO LTD

Non-nickel jewelry 18K platinum capable of avoiding low-temperature brittleness

The invention discloses non-nickel jewelry 18K platinum capable of avoiding low-temperature brittleness. The alloy comprises components including, by weight percent, 0.5 wt.%-0.8 wt.% of Li, 0.4 wt.%-0.6 wt.% of Re, 1.2 wt.%-1.5 wt.% of Ca, 4.0 wt.%-6.0 wt.% of Al, 10.0 wt.%-12.0 wt.% of In, 5.0 wt.%-6.0 wt.% of Ag, and the balance gold. The non-nickel jewelry 18K platinum solves the problem thatthe nickel element to which people are allergic is commonly contained in current K platinum. Through alloy component optimization and innovation, the non-nickel K platinum material friendly to the human body is developed, and the development bottleneck in the jewelry field is effectively broken through. It can be predicted that rich economic gains and social benefits can be obtained due to material implementation and industrialization.

Owner:GUANGZHOU YUZHI TECH CO LTD

Ba-Ca-Mn zinc alloy for top slag type corrosion-resistant hot-dip galvanizing

InactiveCN108330326AExcellent volatility resistanceImprove oxidation resistanceHot-dipping/immersion processesSocial benefitsSlag

The invention discloses a Ba-Ca-Mn zinc alloy for top slag type corrosion-resistant hot-dip galvanizing as well as a processing process of the. The Ba-Ca-Mn zinc alloy comprises the following components in percentage by weight: 0.2-0.3 wt.% of Ba, 0.2-0.4 wt.% of Ca, 1.2-1.8 wt.% of Ge, 0.2-0.4 wt.% of Ni, 1.4-1.6 wt.% of Mn, 0.1-0.2 wt.% of V and the balance of zinc. The material can be applied to hot-dip galvanizing of a steel plate at 320 to 340 DEG C; furthermore, zinc slag formed in the hot-dip galvanizing process has low density, floats above zinc liquid and is convenient to fish. Through the alloy industrialization, great economic and social benefits can be obtained. Along with the development of more engineering application fields, the novel alloy will be certainly and widely applied to more hot-dip galvanizing.

Owner:GUANGZHOU YUZHI TECH CO LTD

High-hardness and anti-corrosion yellow low silver content alloy for Miao silver jewellery and technology thereof

InactiveCN108842088AUnchanged for a long timeWith self-healing functionJewellerySocial benefitsHardness

The invention discloses a high-hardness and anti-corrosion yellow low silver content alloy for Miao silver jewellery and technology thereof. The high hardness and anti-corrosion yellow low silver content alloy comprises, by weight, 0.3-0.5wt.% of P, 0.2-0.4wt.% of C, 0.5-0.8wt.% of Li, 0.3-0.5wt.% of W, 1.0-1.5wt.% of Y, 8.0-1.0wt.% of Zn, 5.0-8.0wt.% of Ni, 40.0-50.0wt.% of Ag, and the balance copper. The material provides a solution for Chinese Miao silver alloy in materials science. Miao silver products have yellow color after processing, and the alloy has excellent high-hardness performance. Implement and industrialization of the material is capable of effectively promoting jewelry industry product renewal and industry upgrading in China. Difficulty in the industry can be overcome, andmeanwhile, abundant economic and social benefits can be obtained.

Owner:GUANGZHOU YUZHI TECH CO LTD

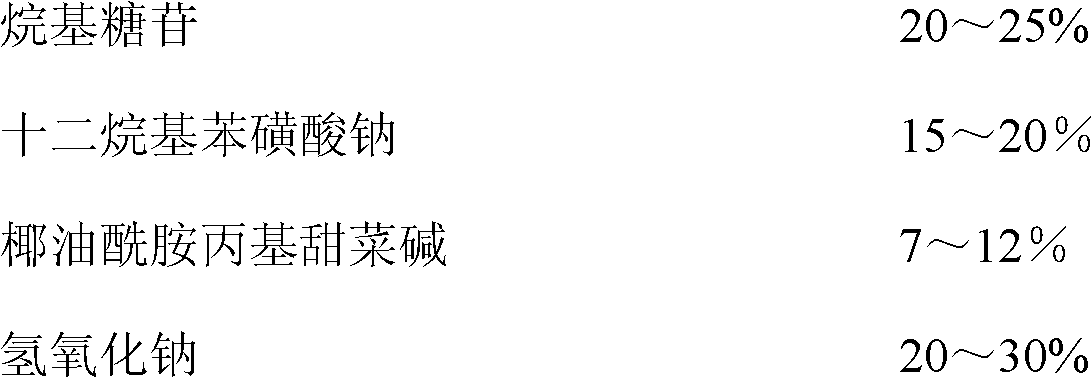

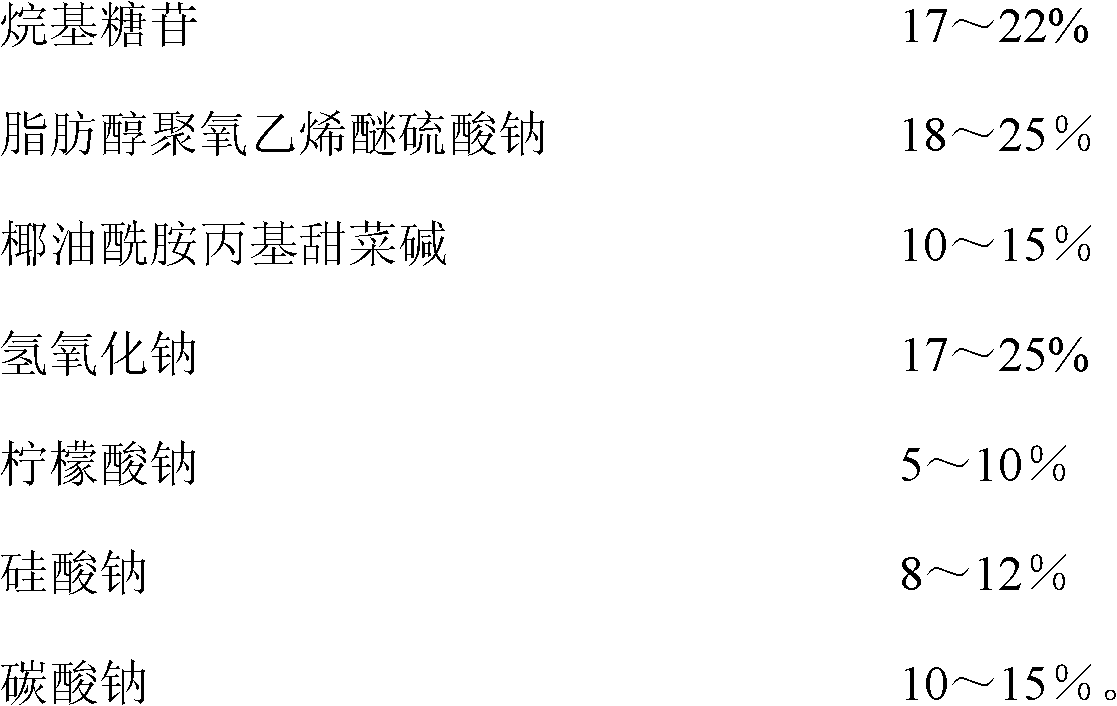

Nano coating modified ceramic microfiltration membrane cleaning agent and preparation method and application thereof

ActiveCN102658034BPermeate flux recoveryEasy to cleanSemi-permeable membranesMicrofiltration membraneActive agent

The invention discloses a nano coating modified ceramic microfiltration membrane cleaning agent, which consists of the following components in percentage by mass: 30 to 57 percent of composite surfactant, 15 to 35 percent of basic hydroxide, and 8 to 40 percent of cleaning aid. The invention also discloses a preparation method and application of the cleaning agent. The cleaning agent has a good cleaning effect, the permeation flux of a cleaned modified ceramic microfiltration membrane can almost be recovered, and the cleaning agent does not have an obvious corrosion effect on the modified ceramic microfiltration membrane and a nano modified oxide and prevents the structure and the performance of the modified ceramic microfiltration membrane from being affected by the cleaning process. Moreover, the cleaning agent is easy to prepare, convenient and feasible to use and high in cleaning efficiency; and the cleaning time is greatly shortened, the energy consumption of a system in the cleaning process is reduced, and secondary pollution to the environment due to the waste liquid of the cleaning agent is avoided.

Owner:重庆兀盾纳米科技有限公司

Os-containing zinc alloy for hot-dip galvanizing of corrosion-resisting spangle-free low-carbon steel

InactiveCN108277391AExcellent volatility resistanceImprove oxidation resistanceHot-dipping/immersion processesZinc alloysCarbon steel

The invention discloses an Os-containing zinc alloy for hot-dip galvanizing of corrosion-resisting spangle-free low-carbon steel and a processing technology of the Os-containing zinc alloy. The Os-containing zinc alloy is prepared from the following components in percentage by weight: 0.5 to 1.2 weight percent of Li, 0.5 to 0.8 weight percent of Os, 0.2 to 0.6 weight percent of Ta, 2.0 to 3.0 weight percent of Si, 0.5 to 0.8 weight percent of Sc, 0.4 to 0.6 weight percent of Sm and the balance of zinc. The development of the alloy can be used for avoiding the phenomenon that spangles generat on the surface of plating parts in the industrial hot-dip galvanizing production. The Os-containing zinc alloy for the hot-dip galvanizing of the corrosion-resisting spangle-free low-carbon steel alsohas the characteristics of low production cost and facilitation for large-scale production.

Owner:GUANGZHOU YUZHI TECH CO LTD

Ba-Pt-Cr aluminum alloy applied to corrosion-resistant copper-clad aluminum wire

InactiveCN108165838AGood flame retardant performanceGood liquidityCopper-clad aluminium wireCorrosion resistant

The invention discloses Ba-Pt-Cr aluminum alloy applied to a corrosion-resistant copper-clad aluminum wire and a machining process of the Ba-Pt-Cr aluminum alloy. The Ba-Pt-Cr aluminum alloy comprisesthe following components in percentage by weight: 0.5-0.8 wt% of Ba, 0.2-0.4 wt% of Pt, 0.5-0.6 wt% of Cr, 0.2-0.4 wt% of Sn, 0.8-1.2 wt% of Y, 0.1-0.3 wt% of Th and the balance of aluminum. The aluminum-barium alloy has excellent mechanical properties and corrosion resistance which the traditional aluminum alloy applied to the copper-clad aluminum wire does not have. The Ba-Pt-Cr aluminum alloyis widely applied to the electric appliance manufacturing industry, the electric wire and cable industry and the radio industry.

Owner:GUANGZHOU YUZHI TECH CO LTD

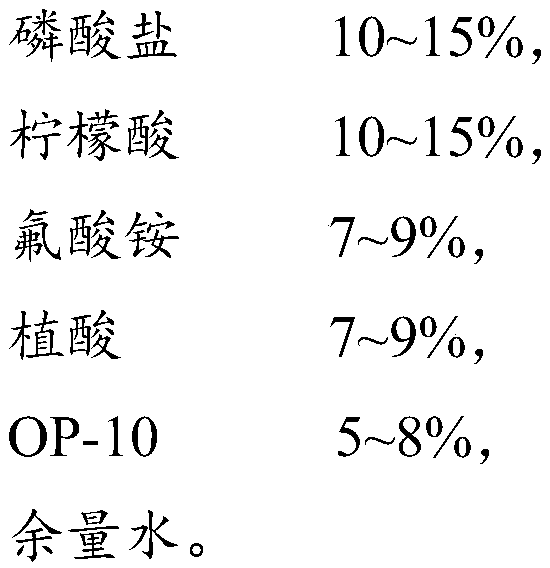

Aluminum cleaning agent as well as preparation and use methods thereof

The invention provides an aluminum cleaning agent. The aluminum cleaning agent is prepared from components in percentage by weight as follows: 10%-15% of phosphate, 10%-15% of citric acid, 7%-9% of ammonium fluorate, 7%-9% of phytic acid, 5%-8% of OP-10 and the balance of water. The invention also provides a preparation method and a use method of the aluminum cleaning agent. The aluminum cleaningagent can effectively remove oil stains and residues on the surface of an aluminum metal material, form films on the surface of the aluminum metal material uniformly, the surface of the aluminum metalmaterial is not obviously corroded after washing, and the aluminum cleaning agent is quick in oil removal and good in stability. Besides, the preparation and use methods of the aluminum cleaning agent are simple and easy to operate and facilitate mass production.

Owner:天津市顺超有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com