Corrosion inhibitor for closed soft water circulating cooling water system and application

A technology of cooling water system and corrosion inhibitor, applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc. Excellent corrosion performance, efficient corrosion inhibition performance and obvious technical advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The production process of the corrosion inhibitor of the present invention is introduced as follows:

[0025] 1.1 Preparation: According to the formula ratio, quantitatively weigh 5-50 parts of triethanolamine borate, 5-50 parts of ascorbic acid, 5-50 parts of urotropine, 1-10 parts of benzotriazole, 1-10 parts of sodium hydroxide Parts, 10-80 parts of water.

[0026] 1.2 Production: Add water to the reaction kettle, start stirring, add triethanolamine borate, ascorbic acid, urotropine, benzotriazole, sodium hydroxide, water, dissolve, continue to stir for about 20 minutes, and mix well Divide it to obtain the preparation of the present invention.

Embodiment 2

[0028] The production process of the corrosion inhibitor of the present invention is introduced as follows:

[0029] 2.1 Preparation: According to the formula ratio, quantitatively weigh 5-50 parts of triethanolamine borate, 5-50 parts of ascorbic acid, 5-50 parts of urotropine, 1-10 parts of benzotriazole, 1-10 parts of sodium hydroxide Parts, 10-80 parts of water.

[0030] 2.2 Production: Add water to the reaction kettle, start stirring, add triethanolamine borate, benzotriazole, and sodium hydroxide, continue to stir after dissolution for about 20 minutes, mix and pack into preparation A; add ascorbic acid , Urotropine, and water are added to the reaction kettle, stirred and dissolved, and then continue to stir for about 20 minutes. After mixing, they are divided into preparation B; the composition preparation of the present invention is obtained.

Embodiment 3

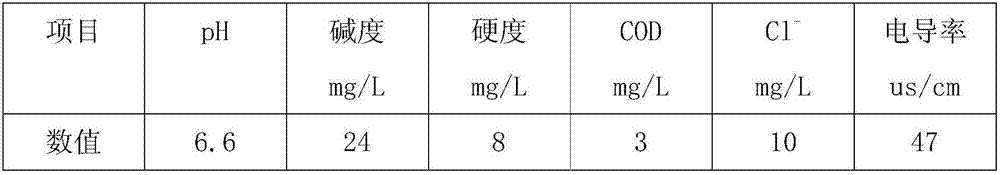

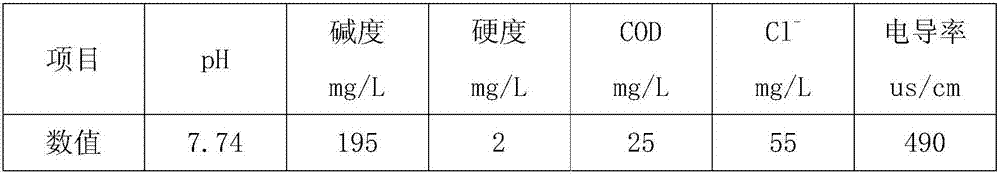

[0032] The invention is used as a corrosion inhibitor for the closed soft water circulating cooling water of a blast furnace, and a corrosion inhibitor performance test is carried out for a certain water quality.

[0033] 3.1 Test conditions

[0034] Test water quality: test water is a blast furnace replenishing water in Hebei area; water quality stabilizer: the invention, used in the corrosion inhibitor of the closed soft water circulating cooling water system of blast furnace, the added amount is the preparation 200mg / L commercial concentration; test water temperature: 50± 1℃; linear speed of test piece: 75r / min; distance between upper end of test piece and test liquid surface: more than 2cm; size and surface area of test piece: 50×25×2mm, 28cm 2 ; Test time: 120 hours; Number of test slices: three in each cup; Test slice material: A3 carbon steel, stainless steel, copper.

[0035] 3.2 Test method

[0036] Refer to the "Determination of Water Treatment Agent Corrosion Inhibition P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com