Special cooling liquid for internal combustion locomotives

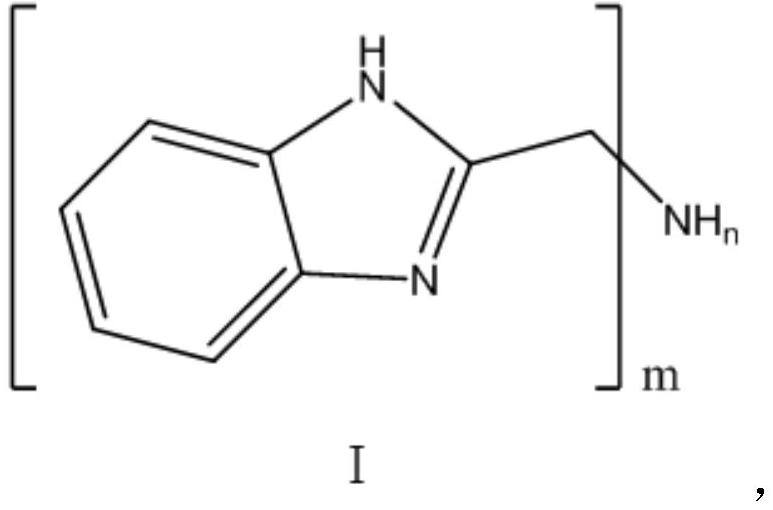

A technology for diesel locomotive and coolant, applied in the field of metal anti-corrosion, can solve problems such as system corrosion and poor scale inhibition effect, and achieve the effect of efficient corrosion inhibition and excellent corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the locomotive cooling system, in addition to heat dissipation equipment, it is mainly composed of iron-based alloys, such as carbon steel, cast iron, stainless steel, etc. On the one hand, the corrosion of iron-based alloys will cause the aging of the locomotive cooling system itself. More importantly, the corrosion of iron-based alloys will seriously aggravate the corrosion of the H-85 brass material of the cooling equipment, which is the main cause of H-85 brass corrosion and perforation. one of the reasons. Therefore, for diesel locomotive coolant, the corrosion inhibition ability of corrosion inhibitors on subsidized alloys should be studied first.

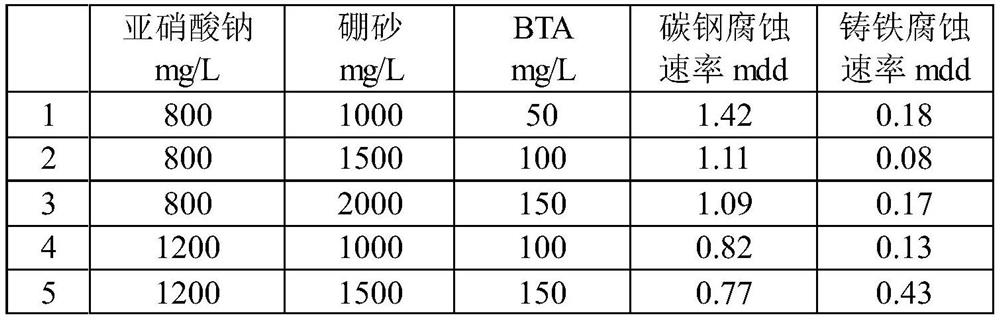

[0024] Orthogonal experiment was carried out with corrosion inhibitor sodium nitrite, borax and benzotriazole as three factors. Orthogonal experiment design, calculated per liter of water, adding three levels of sodium nitrite 800mg / L, 1200mg / L, and 1800mg / L to the secondary reverse osmosis water, and adding three ...

Embodiment 2

[0040] In this embodiment, the special coolant for diesel locomotives is calculated by every liter of water. In the secondary reverse osmosis water, 1800 mg / L of sodium nitrite, 2000 mg / L of borax, 100 mg / L of BTA, 500 mg / L of sodium molybdate, n-heptanoic acid and 300 mg / L of aspartic acid (equal mass ratio) and 800 mg / L of benzimidazolamine compounds form a cooling liquid, and a sodium hydroxide solution is used to adjust the pH of the cooling liquid to 9.2.

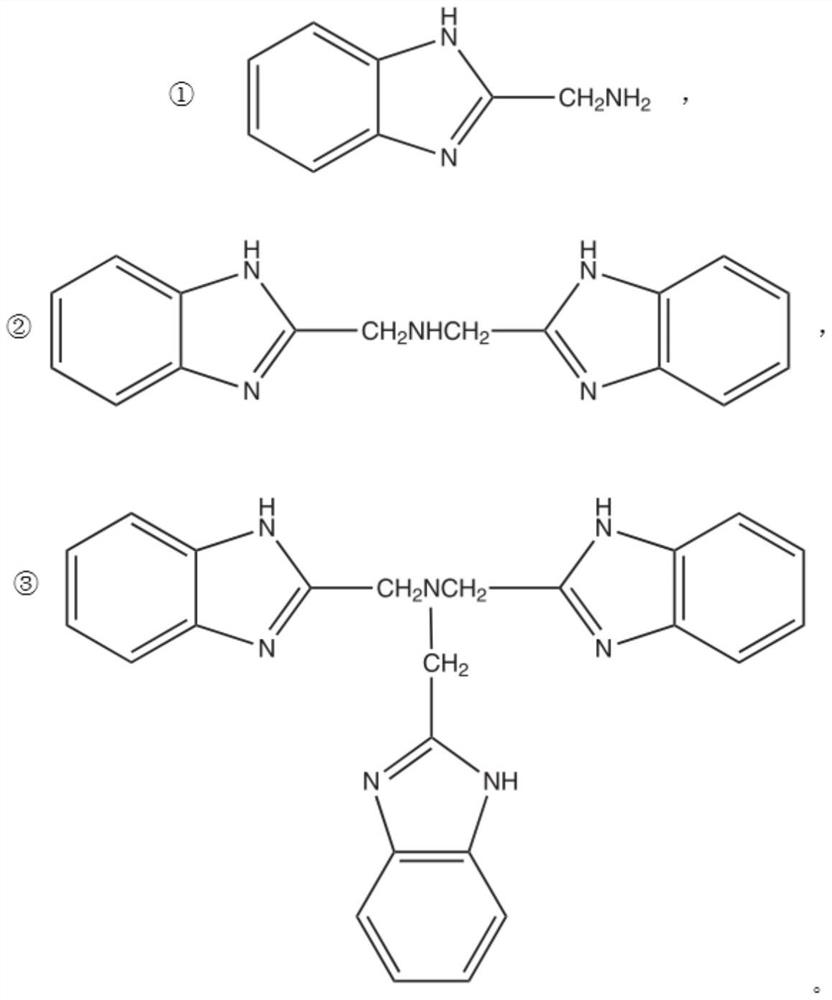

[0041] Wherein the benzimidazolamine compound has the following formula ② structure:

[0042]

[0043] The preparation method of the cooling liquid: Dissolve sodium nitrite and borax in part of the secondary reverse osmosis water according to the formula quantity, add benzotriazole, stir and dissolve at a stirring speed of 1500rpm; then add sodium molybdate and keep stirring speed and stir to dissolve; then add n-heptanoic acid and aspartic acid, maintain the stirring speed and stir to dissolve; finally add the benz...

Embodiment 3

[0045] The internal-combustion locomotive special coolant of the present embodiment is calculated by every liter of water, and sodium nitrite 1800mg / L, borax 2000mg / L, BTA100mg / L, ammonium tungstate 400mg / L, sebacic acid and 600 mg / L of aspartic acid (equal mass ratio) and 600 mg / L of benzimidazolamine compounds form a cooling liquid, and a sodium hydroxide solution is used to adjust the pH of the cooling liquid to 9.6.

[0046] Wherein the benzimidazolamine compound has the following formula ③ structure:

[0047]

[0048] The preparation method of the cooling liquid: Dissolve sodium nitrite and borax in part of the secondary reverse osmosis water according to the formula quantity, add benzotriazole, stir and dissolve at a stirring speed of 1500rpm; then add ammonium tungstate, and maintain the stirring speed and stir to dissolve; then add sebacic acid and aspartic acid, maintain the stirring speed and stir to dissolve; finally add the benzimidazole amine compound of formul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com