Adsorbent and preparation method thereof

An adsorbent and binder technology, applied in the field of adsorbent and its preparation, can solve the problems of complicated preparation process, equipment corrosion, small specific surface area of adsorbent, etc., and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

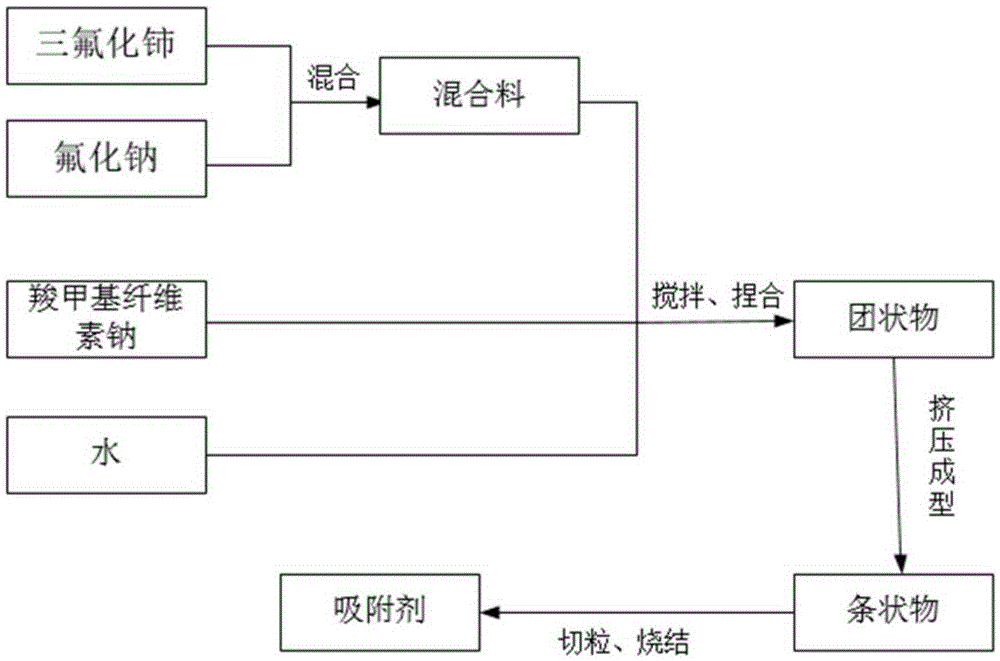

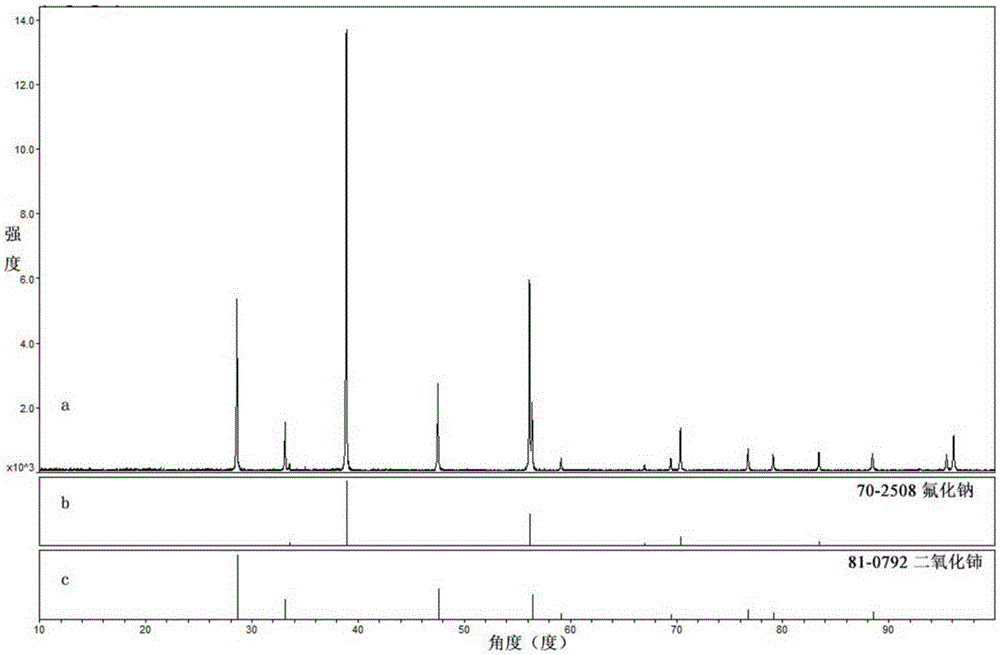

[0028] according to figure 1 In the process flow shown, 1.00g of cerium trifluoride is added to 15.84g of sodium fluoride powder, and mixed thoroughly to obtain a mixture; then 1g of sodium carboxymethylcellulose is weighed, and added to the mixture to mix, Then gradually add 5ml of water, and keep stirring and kneading during the addition of water, and finally form a dough. Put the dough into the screw extruder and extrude into strips, then cut into The particles are put into the muffle furnace for sintering, the sintering temperature is 800 ℃, and the heat preservation is 2h, and the adsorbent is obtained, and its specific surface area is 0.80m 2 / g, its X-ray diffraction pattern (XRD pattern) such as figure 2 shown.

[0029] figure 2 Among them, a represents the XRD pattern of the adsorbent made in Example 1; b represents the standard XRD pattern of sodium fluoride crystals in the XRD standard library (JCPDs), and the numbering is 70-2508; c represents the cerium dio...

Embodiment 2

[0031] Add 3.75g of cerium trifluoride to 15.20g of sodium fluoride powder, mix thoroughly to obtain a mixture; then weigh 1g of sodium carboxymethylcellulose, add it to the mixture and mix, then gradually add 8ml of water, And keep stirring and kneading during the addition of water, and finally form a dough. Put the dough into the screw extruder and extrude into strips, then cut into The particles are put into the muffle furnace for sintering, the sintering temperature is 750°C, and the heat preservation is 2h, the adsorbent is obtained, and its specific surface area is 0.85m 2 / g.

[0032] There is almost no difference between the XRD pattern of the adsorbent prepared in Example 2 and Example 1 by X-ray diffraction.

[0033] Compared with the specific surface area of pure sodium fluoride adsorbent, the specific surface area of the adsorbent in the present invention is significantly improved. The improvement of the specific surface area in this field is generally condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com