Aluminum cleaning agent as well as preparation and use methods thereof

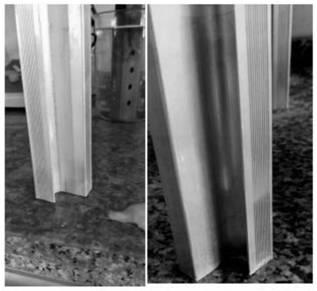

A technology of aluminum lotion and mixed solution, which is applied in the field of metal surface treatment, and can solve the problems of poor cleaning effect, a lot of oil, dust, and environmental pollution on the surface of aluminum materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides the preparation method of aluminum lotion described in above technical scheme, comprises the following steps:

[0034] (1) Part of the water is mixed with phosphate to obtain a phosphate aqueous solution;

[0035] (2) mixing the phosphate aqueous solution obtained in the step (1) with citric acid to obtain the first mixed solution;

[0036] (3) mixing the first mixed solution obtained in the step (2) with phytic acid to obtain a second mixed solution;

[0037] (4) mixing the second mixed solution obtained in the step (3) with ammonium fluoride to obtain the third mixed solution;

[0038] (5) mixing the third mixed solution obtained in the step (4) with OP-10 to obtain the fourth mixed solution;

[0039] (6) Mix the fourth mixed solution obtained in the step (5) with the remaining part of water, and the resulting mixed solution is aluminum lotion.

[0040] The invention mixes part of water and phosphate to obtain phosphate aqueous soluti...

Embodiment 1

[0053] Preparation of Aluminum Lotion:

[0054] Step 1: Add 200KG of pure water into the reaction kettle, add 150KG of phosphate into the pure water with the stirring device of the reaction kettle, and continue stirring at 650r / min for 40 minutes to make the phosphate evenly stirred in the pure water;

[0055] Step 2: Add 150KG of citric acid to the reaction kettle at a rotating speed of 650r / min. After adding citric acid, adjust the rotating speed of the stirring device to 500r / min, and continue stirring for 40 minutes;

[0056] Step 3: Add phytic acid 90KG to the reaction kettle, and the stirring device continuously stirs at a speed of 500r / min for 20min;

[0057] Step 4: Add 90KG of ammonium fluoride to the reactor, and the stirring device continuously stirs at a speed of 500r / min for 20min;

[0058] Step 5: Add OP-1080KG to the reactor, and the stirring device keeps stirring at a speed of 500r / min for 25 minutes;

[0059] Step 6: Add 240KG of pure water to the reaction k...

Embodiment 2

[0065] Preparation of Aluminum Lotion:

[0066] Step 1: Add 250KG of pure water to the reactor, use the stirring device of the reactor to add 100KG of phosphate into the pure water, and keep stirring at 650r / min for 40 minutes to make the phosphate evenly stirred in the pure water;

[0067] Step 2: Add 100KG of citric acid to the reaction kettle at a rotating speed of 650r / min. After adding the citric acid, adjust the rotating speed of the stirring device to 500r / min, and continue stirring for 40 minutes;

[0068] Step 3: Add 70KG of phytic acid to the reaction kettle, and the stirring device continuously stirs at a speed of 500r / min for 20min;

[0069] Step 4: Add 70KG of ammonium fluoride to the reactor, and the stirring device continuously stirs at a speed of 500r / min for 20min;

[0070] Step 5: Add OP-1050KG to the reactor, and the stirring device keeps stirring at a speed of 500r / min for 25 minutes;

[0071] Step 6: Add 360KG of pure water to the reaction kettle, and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com