Preparation method of corrosion-resistant titanium alloy micro-arc oxidation coating

A micro-arc oxidation, titanium alloy technology, applied in the direction of coating, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems of complex process and unenvironmental protection, and achieve the effect of improving the film forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

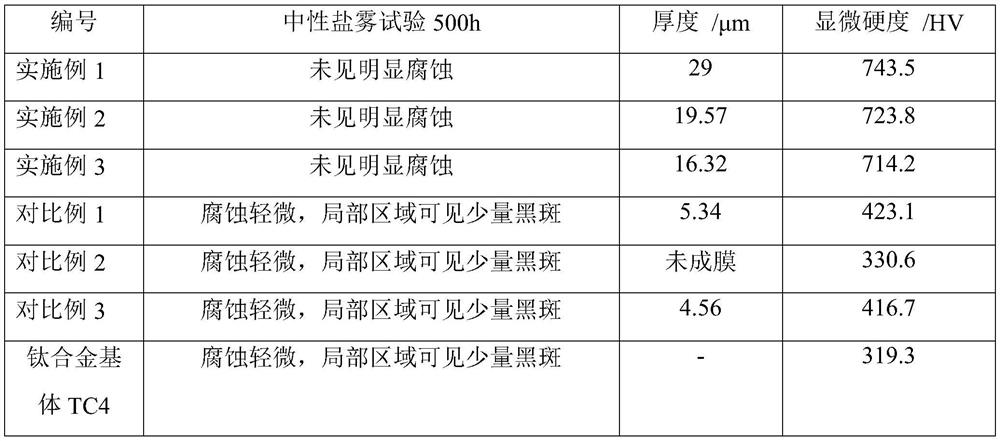

Examples

preparation example Construction

[0019] The invention provides a method for preparing a corrosion-resistant titanium alloy micro-arc oxidation coating, comprising the following steps:

[0020] a. Polish and polish the titanium alloy, clean it and dry it with cold air for later use;

[0021] b. Prepare the electrolyte, the content of each component in the electrolyte is: NaOH 1~5g / L, NaOH 2 SiO 3 10~20g / L, Na 3 PO 4 5~15g / L;

[0022] c. putting the titanium alloy treated in step a into the electrolyte solution described in step b as an anode, using stainless steel as a cathode, under the conditions of voltage 400-450V, frequency 400-500Hz, and duty ratio 20-40%, Anodic current is applied to the titanium alloy sample and treated for 5-20 minutes to form a stable micro-arc on the surface, and a micro-arc oxidation coating is prepared.

[0023] Wherein, in the preparation method of the corrosion-resistant titanium alloy micro-arc oxidation coating, the titanium alloy described in step a is a TC-type titani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com