Anticorrosive paint composition containing self-emulsifying curing agent and preparation method of anticorrosive paint

A self-emulsifying anti-corrosion coating technology, which is applied in the preparation of organic compounds, anti-corrosion coatings, chemical instruments and methods, etc., can solve problems such as safety and environmental pollution of metal anti-corrosion coatings, achieve unique methods, improve curing effects, and prepare processes simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

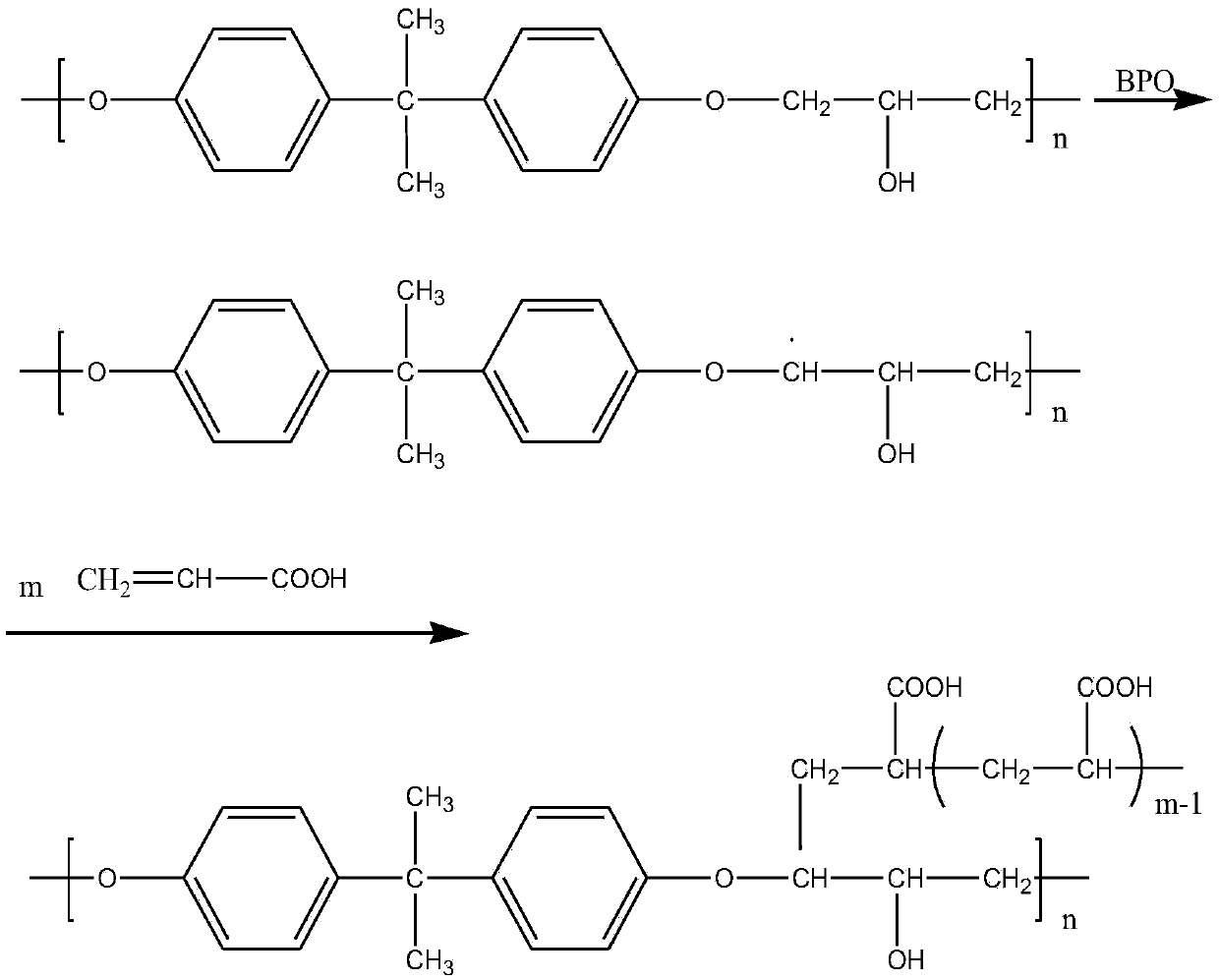

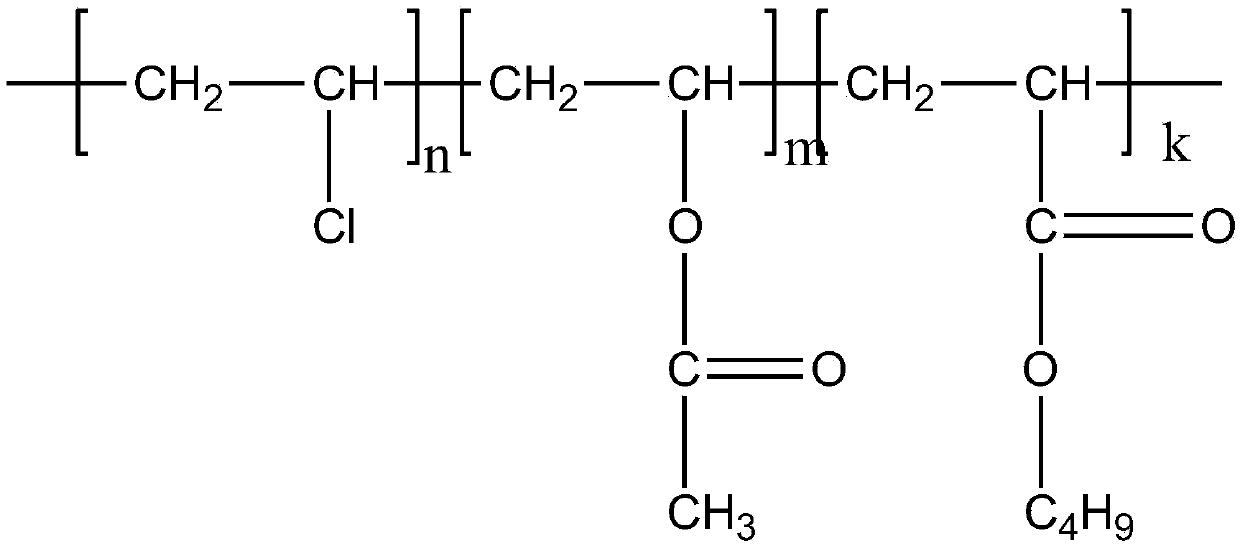

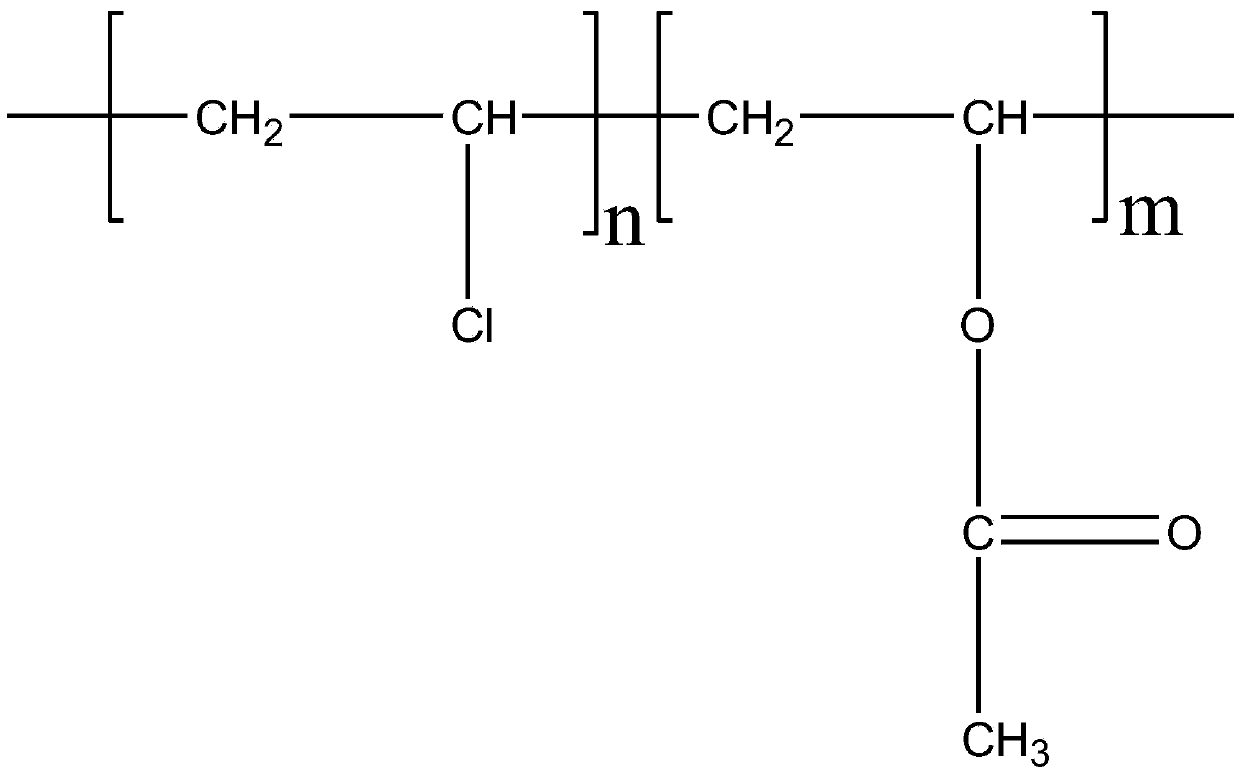

Method used

Image

Examples

Embodiment 1

[0040] 1. The formula of the composition

[0041] 1. Prepare component A and content of composition according to mass percentage:

[0042]

[0043]

[0044] 2. Prepare component B and content of composition according to mass percentage:

[0045]

[0046] 3. Prepare the content of the composition according to the mass ratio: A:B=10:1.

[0047] 2. Preparation method

[0048] Water-based epoxy ester resin, vinyl chloride-vinyl acetate-butyl acrylate resin, vinyl chloride-vinyl acetate resin, mica, talcum powder, defoamer and emulsifier in component A are mixed with deionized water according to the mass ratio Dissolve, stir to form an emulsion, and set aside;

[0049] At a temperature of 50°C and a speed of 1000r / min, grind the emulsion prepared in step 1 on a three-roll mill to a particle size of 0.1-5μm, and place it at room temperature; mix the self-emulsifying curing agent, three Ethylenediamine, diethylenetriamine, sodium nitrite and zinc phosphate are dissolved ...

Embodiment 2

[0053] 1. The formula of the composition

[0054] 1. Prepare component A and content of composition according to mass percentage:

[0055]

[0056]

[0057] 2. Prepare component B and content of composition according to mass percentage:

[0058]

[0059] 3. Prepare the content of the composition according to the mass ratio: A:B=9:1.

[0060] Two, preparation method is the same as embodiment 1

[0061] 3. Beneficial effects

[0062] The composition obtained in this example is coated on the tinplate, and can be cured at room temperature, and it will be dry in 1 hour; the adhesion force measured by the cross-cut method reaches level 1; it is measured by the salt spray test, and there is no obvious corrosion in the salt spray corrosion test after 130 hours lesion.

Embodiment 3

[0064] 1. The formula of the composition

[0065] 1. Prepare component A and content of composition according to mass percentage:

[0066]

[0067] 2. Prepare component B and content of composition according to mass percentage:

[0068]

[0069]

[0070] 3. Prepare the content of the composition according to the mass ratio: A:B=8:1.

[0071] Two, preparation method is the same as embodiment 1

[0072] 3. Beneficial effects

[0073] The composition obtained in this example is coated on the tinplate, and it can be cured at room temperature, and it will be dry in 1 hour; the adhesion force measured by the cross-hatch method reaches level 1; it is measured by the salt spray test, and there is no obvious corrosion in the salt spray corrosion test after 165 hours lesion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com