Nano coating modified ceramic microfiltration membrane cleaning agent and preparation method and application thereof

A technology of ceramic microfiltration and modification, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the deterioration of oil-water separation performance of modified ceramic microfiltration membranes, corrosion of nano-modified oxide particles, Affect the modification effect of ceramic microfiltration membrane, etc., to achieve the effect of shortening the cleaning time, high natural degradation rate and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

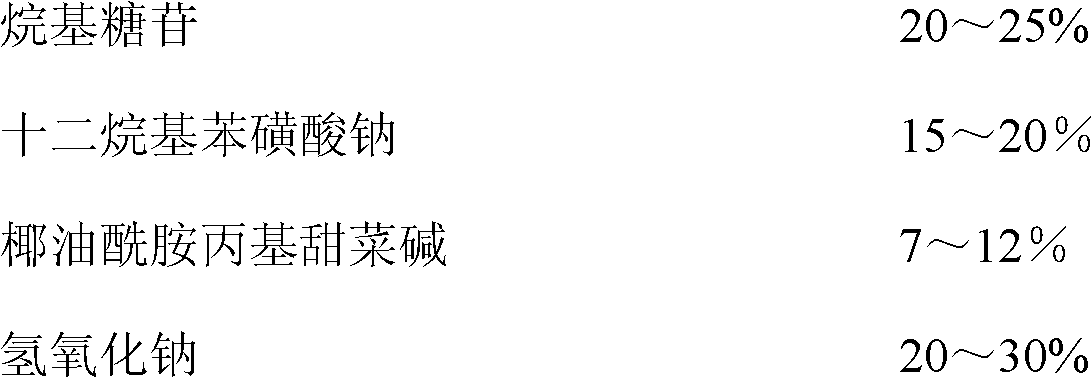

[0036] The present embodiment nano-coating modification modified ceramic microfiltration membrane cleaning agent, its composition by mass percentage is as follows:

[0037]

[0038] The preparation method of the cleaning agent in this example is as follows: add the above-mentioned components into a container device with stirring and grinding, and stir and mix at room temperature for 3 hours to obtain the finished cleaning agent.

[0039] The cleaning agent in this example is used to clean the nano-oxide modified ceramic microfiltration membrane polluted by the oily waste water of the cold rolling emulsion, and the cleaning method is as follows:

[0040] a. The cleaning agent is prepared into a cleaning solution (pH<12) with a mass percent content of 1.5%, for use;

[0041] b. After the ceramic microfiltration membrane device is emptied of the feed liquid, wash it with hot water at 60°C for 5 minutes;

[0042] c. After the cleaning solution is heated to 60°C, clean the cera...

Embodiment 2

[0046] The present embodiment nano-coating modification modified ceramic microfiltration membrane cleaning agent, its composition by mass percentage is as follows:

[0047]

[0048] The preparation method of the cleaning agent in this example is as follows: add the above-mentioned components into a container device with stirring and grinding, and stir and mix at room temperature for 5 hours to obtain the finished cleaning agent.

[0049] The cleaning agent in this example is used to clean the nano-oxide modified ceramic microfiltration membrane polluted by the oily waste water of the cold rolling emulsion, and the cleaning method is as follows:

[0050] a. The cleaning agent is prepared into a cleaning solution (pH<12) with a mass percent content of 1.3%, for use;

[0051] b. After the ceramic microfiltration membrane device is emptied of the feed liquid, wash it with hot water at 60°C for 5 minutes;

[0052] c. After the cleaning solution is heated to 60°C, clean the cera...

Embodiment 3

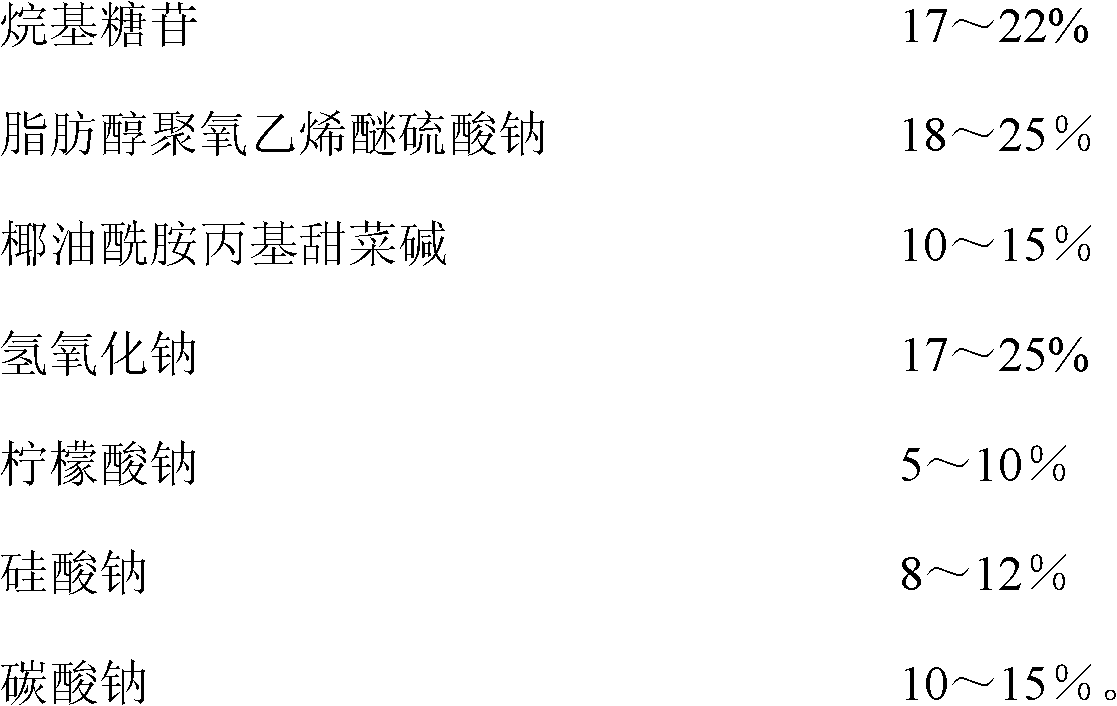

[0056] The present embodiment nano-coating modification modified ceramic microfiltration membrane cleaning agent, its composition by mass percentage is as follows:

[0057]

[0058] The preparation method of the cleaning agent in this example is as follows: add the above-mentioned components into a container device with stirring and grinding, and stir and mix at room temperature for 4 hours to obtain the finished cleaning agent.

[0059] The cleaning agent in this example is used to clean the nano-oxide modified ceramic microfiltration membrane polluted by the oily waste water of the cold rolling emulsion, and the cleaning method is as follows:

[0060] a. The cleaning agent is prepared into a cleaning solution (pH<12) with a mass percent content of 2.0%, and it is ready for use;

[0061] b. After the ceramic microfiltration membrane device is emptied of the feed liquid, wash it with hot water at 60°C for 5 minutes;

[0062] c. After the cleaning solution is heated to 60°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com