High-temperature acidizing corrosion inhibitor as well as preparation method and application thereof

A technology for acidizing corrosion inhibitors and corrosion inhibitors, which can be used in chemical instruments and methods, earth-moving drilling and production, wellbore/well components, etc. Excellent corrosion performance, extended service life, and no pollutant emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

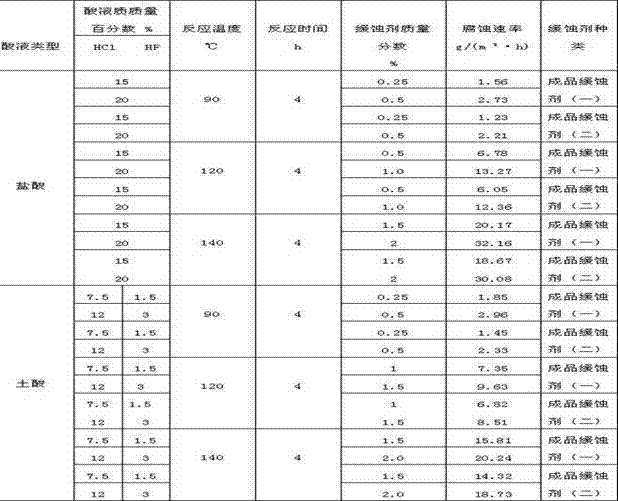

Image

Examples

Embodiment 1

[0039] Example 1: methanol 50, acetone 20, paraformaldehyde 13, heteroaniline 12, hydrochloric acid 5, compounding agent propynyl alcohol 12.

Embodiment 2

[0040] Example 2. Ethanol 55, aliphatic ketone 15, benzaldehyde 10, cyclohexylamine 5, oleic acid 5, compounding agent propynyl alcohol 10.

[0041] two. Preparation method embodiment of high temperature acidification corrosion inhibitor

[0042] It is divided into two parts: the preparation of the parent corrosion inhibitor and the preparation of the finished corrosion inhibitor. Synthesize the matrix corrosion inhibitor first, and then compound to obtain the finished high-temperature acidification corrosion inhibitor. The operation is as follows:

[0043] Example 1

[0044] 1. Preparation of parent corrosion inhibitor:

[0045] step one:

[0046] According to the parts by weight, take 50 parts of methanol, 20 parts of acetone, 13 parts of paraformaldehyde, 12 parts of aniline, and 5 parts of hydrochloric acid into the reaction kettle in turn, react at 95°C for 5-7 hours, and keep warm for 4 hours to obtain the matrix Corrosion inhibitor.

[0047] 2. Preparation of fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com