Automatic non-driven beam-pumping unit balance adjusting device and method

A beam pumping unit and self-adjusting technology, which is applied in the fields of earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problem of poor service life, poor safety and reliability, wear and tear of mechanical drive parts, and high cost of materials. and other problems, to achieve the effect of reliable work, improved power factor, and improved balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

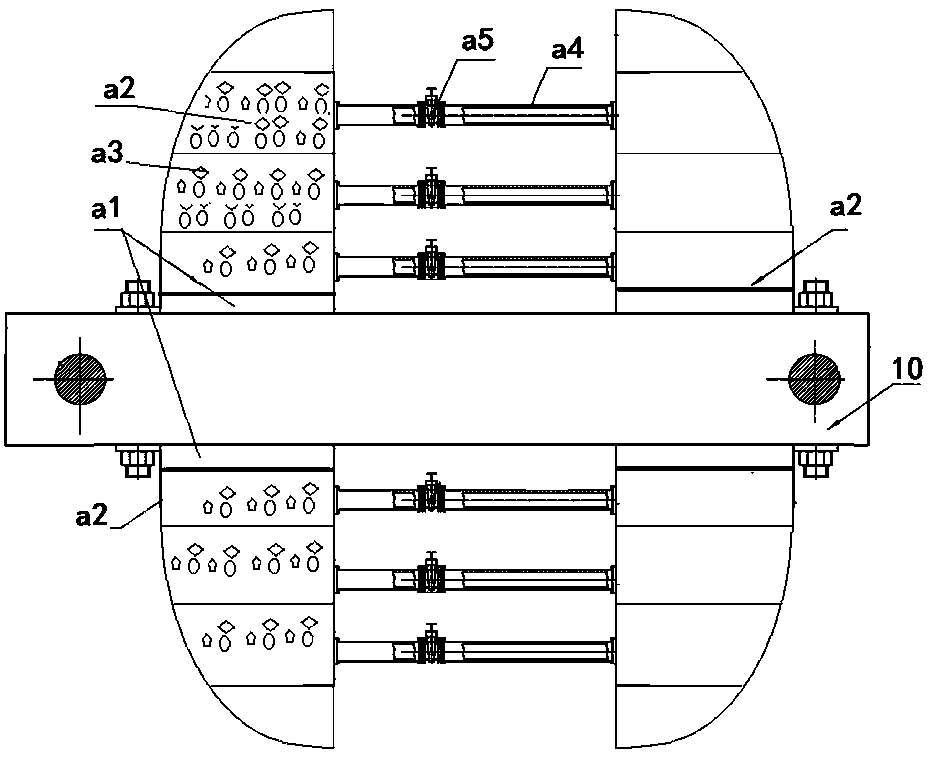

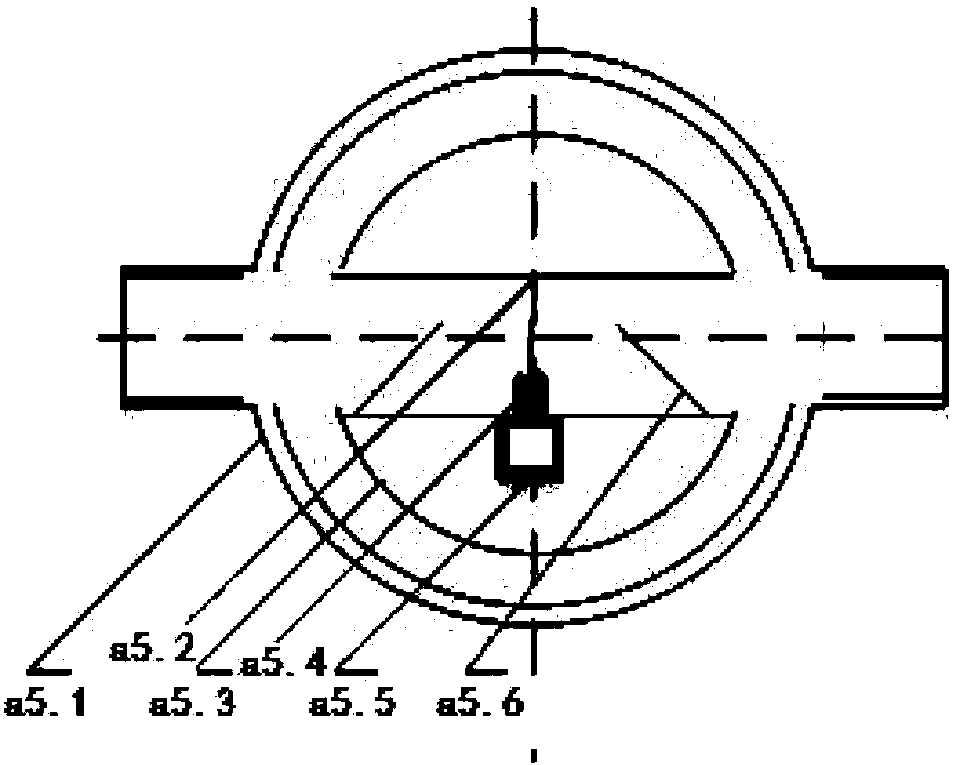

[0069] Embodiment 2, the present invention takes six groups of sand storage boxes as an example: with reference to the attached Figure 6

[0070] When the balance rate is within the unbalanced range of underbalance, initially select the F strategy in the adjustment scheme table in Example 1, and move the iron sand pellets from the sixth sand storage box to the third sand storage box. By default, the iron ore in the large-volume sand storage box is moved first, and the iron ore in the small-volume sand storage box is moved last. The current position of the iron ore is judged through the storage of the control adjustment module, and a movement command is initiated for the sand storage box that is not in the desired position.

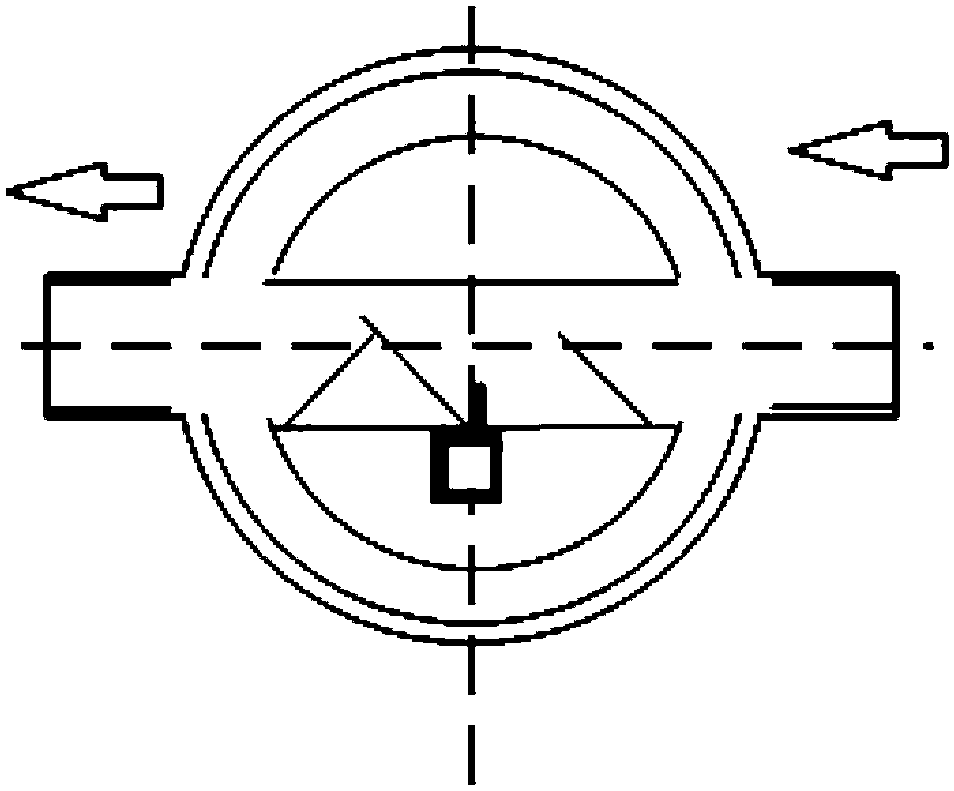

[0071] Assume that the positions of the above three sand storage boxes all need to be adjusted. By default, the sixth sand storage box to the third sand storage box are adjusted preferentially. At this time, the position of the crank in the complete rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com