Vacuum freezing drying machine

A vacuum freeze-drying and drying technology, which is applied in the direction of non-progressive dryers, dryers, refrigerators, etc., can solve the problems of troublesome cleaning and complicated operation, and achieve the effect of convenient maintenance, simple internal structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

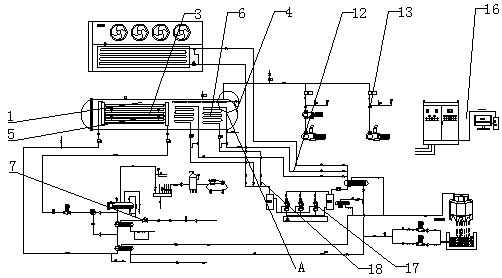

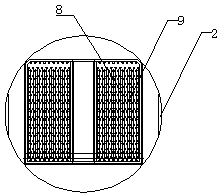

[0036] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a vacuum freeze dryer provided by the present invention includes: a material drying and freezing box 1, and an observation window 2 is installed on the side wall of the material drying and freezing box. One side of the material drying and freezing box body is provided with a drying chamber 3, and the other side is provided with a cold trap chamber 4, the drying chamber communicates with the cold trap chamber, and the inside of the drying chamber is provided with an evaporation pipe 5; A cold trap tube 6 is provided in the cold trap chamber.

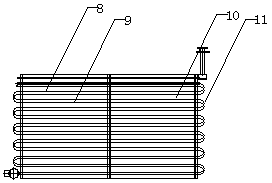

[0037]The heating system 7 is connected to the evaporating pipe; the heating system is used to heat the drying chamber; the evaporating pipe includes a plurality of first evaporating coils 8 and a plurality of second evaporating coils 9, and the first evaporating Both the coil and the second evaporating coil include a plurality of horizontal tubes 10 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com