Construction method of cement rotary kiln kilneye castable

A technology of cement rotary kiln and construction method, which is applied in the direction of furnace, lining repair, lighting and heating equipment, etc. It can solve problems such as tearing off and unsuccessful setting of expansion joints, so as to increase service life, save construction materials and ensure construction quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

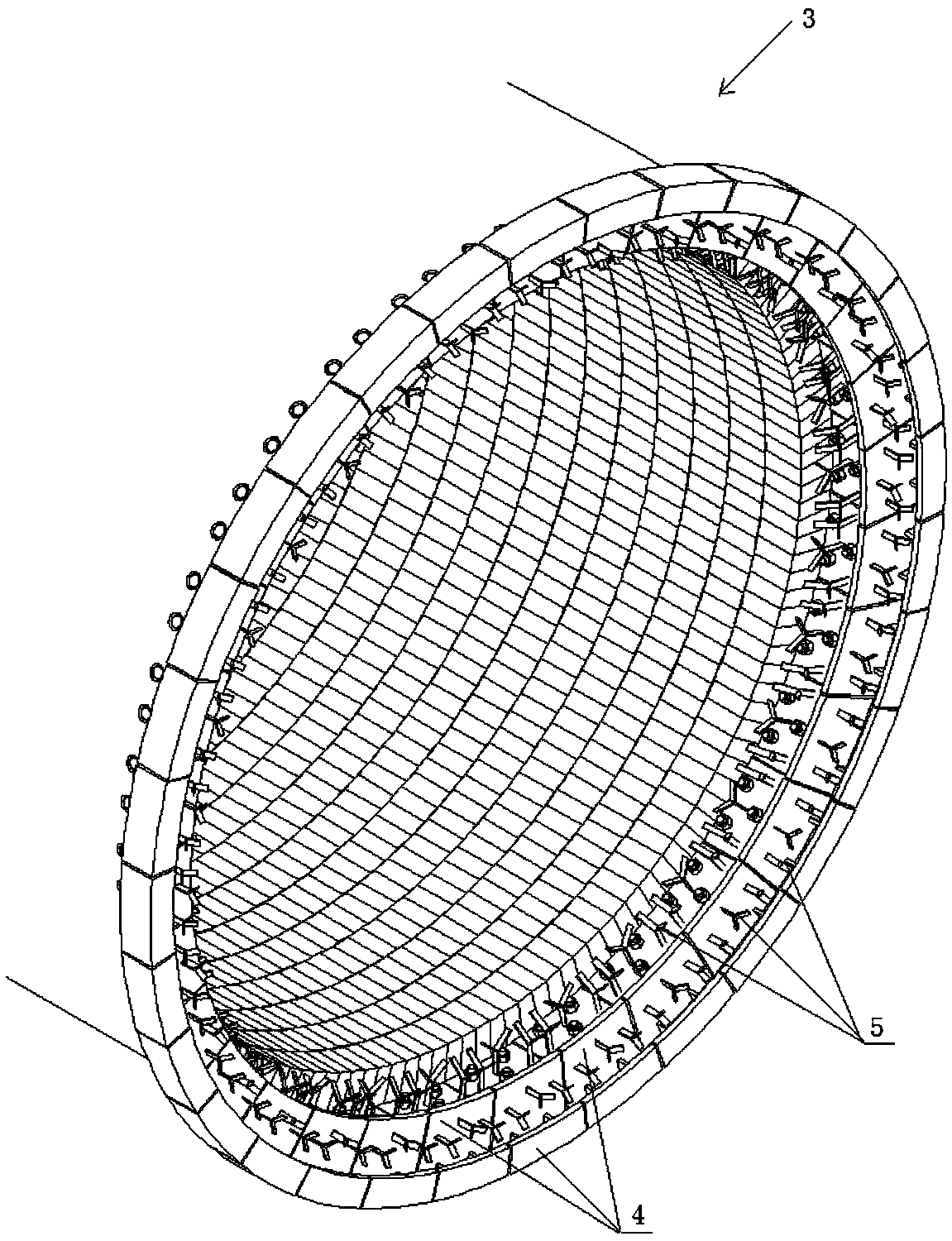

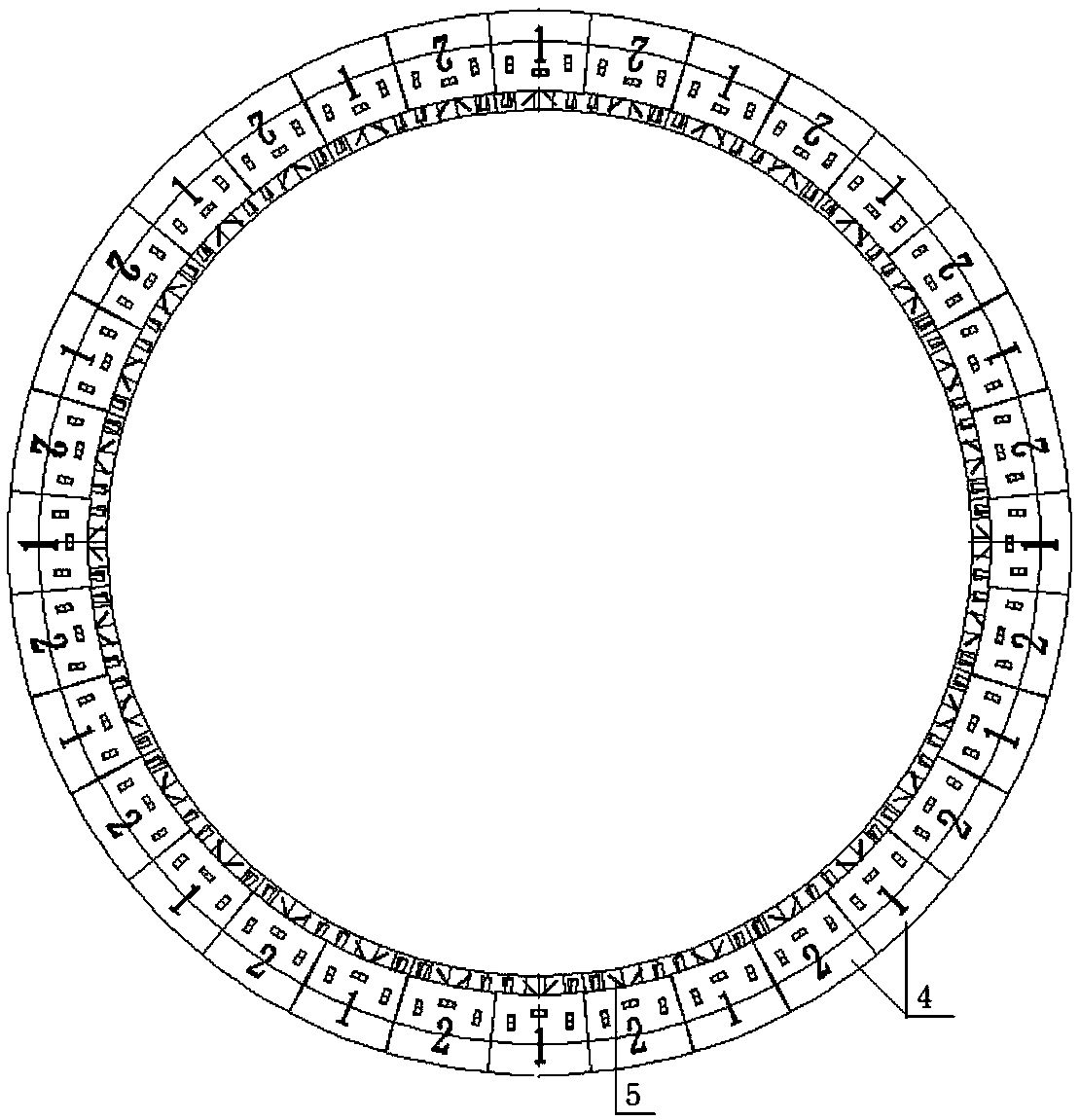

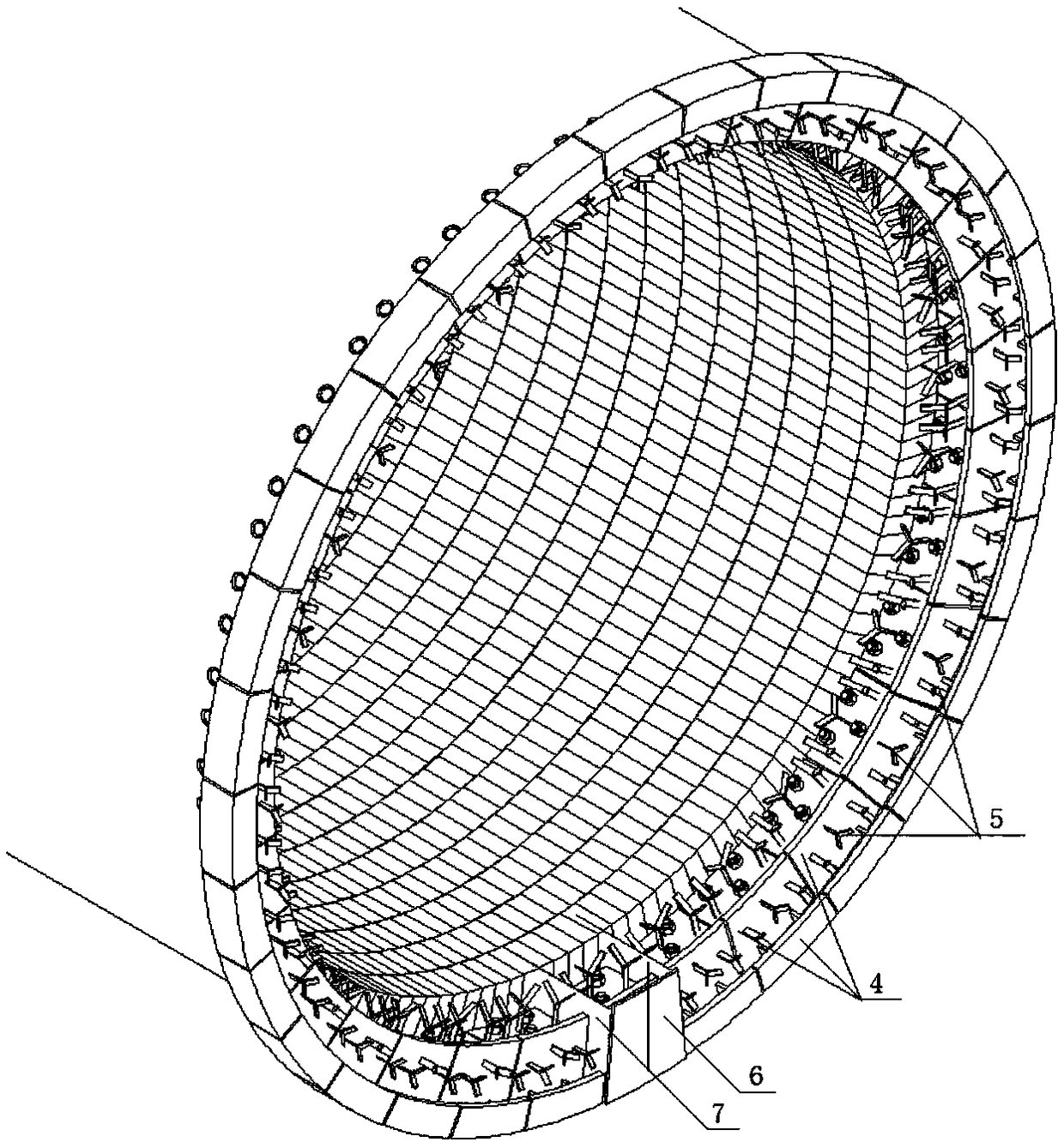

[0036] The existing rotary kiln mouth pouring material construction method usually adopts a sequential construction method, and the kiln mouth pouring material is poured at one time. This construction method is likely to cause problems such as uneven expansion joints, pouring material falling off, damage to the kiln mouth, and low construction efficiency. , in order to solve the above problems, the present invention provides a construction method of pouring material for cement rotary kiln kiln mouth, the method divides a plurality of pouring blocks according to the number of protective iron blocks at the kiln mouth of the rotary kiln, and the pouring blocks are constructed at intervals, which is convenient for the construction process The setting of the middle expansion joint can ensure that the expansion joint is set evenly, and there will be no large-scale damage or falling off of the castable.

[0037] The construction method of the pouring material for the cement rotary kil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com