A torque measuring device

A technology of torque measurement and torque, which is applied in the direction of measuring device, torque measurement, power measurement, etc., can solve the problems of complicated mechanical alignment, time-consuming, difficult installation, etc., and achieve simple and convenient installation and maintenance, and strong environmental adaptability , not easy to damage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

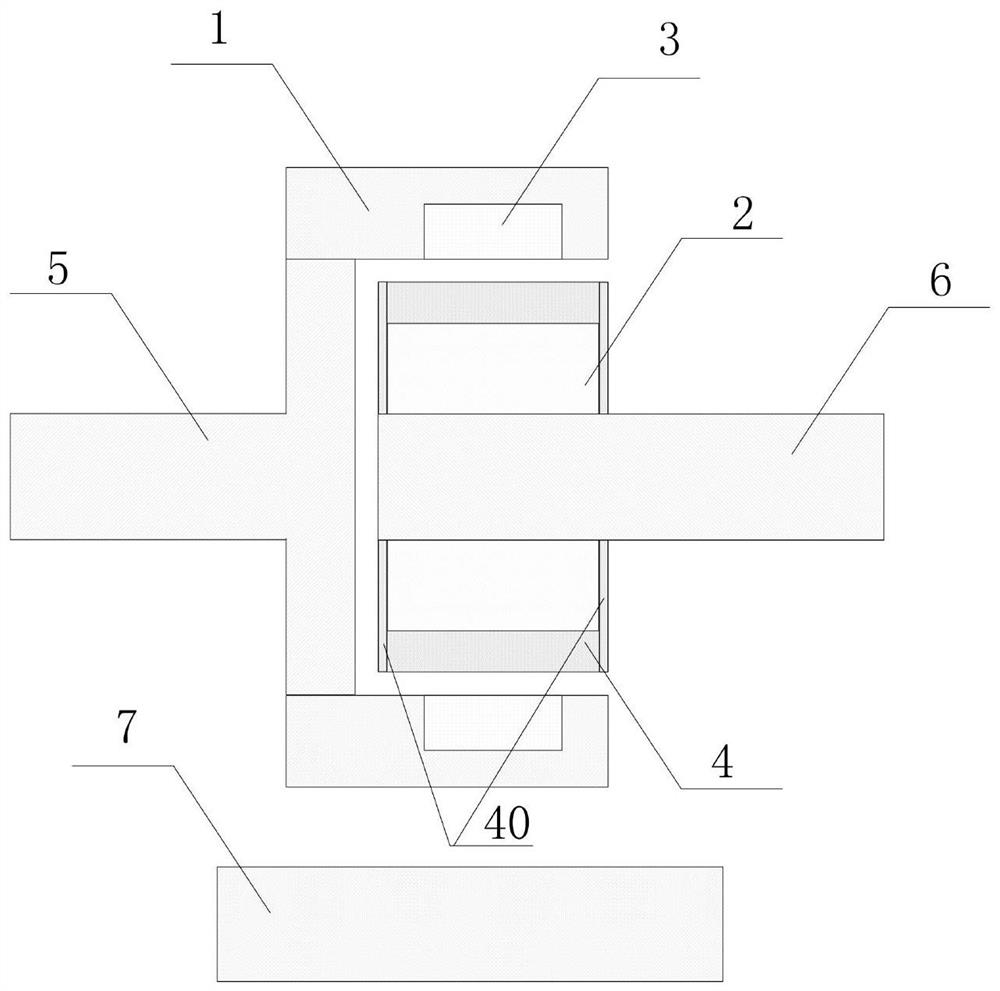

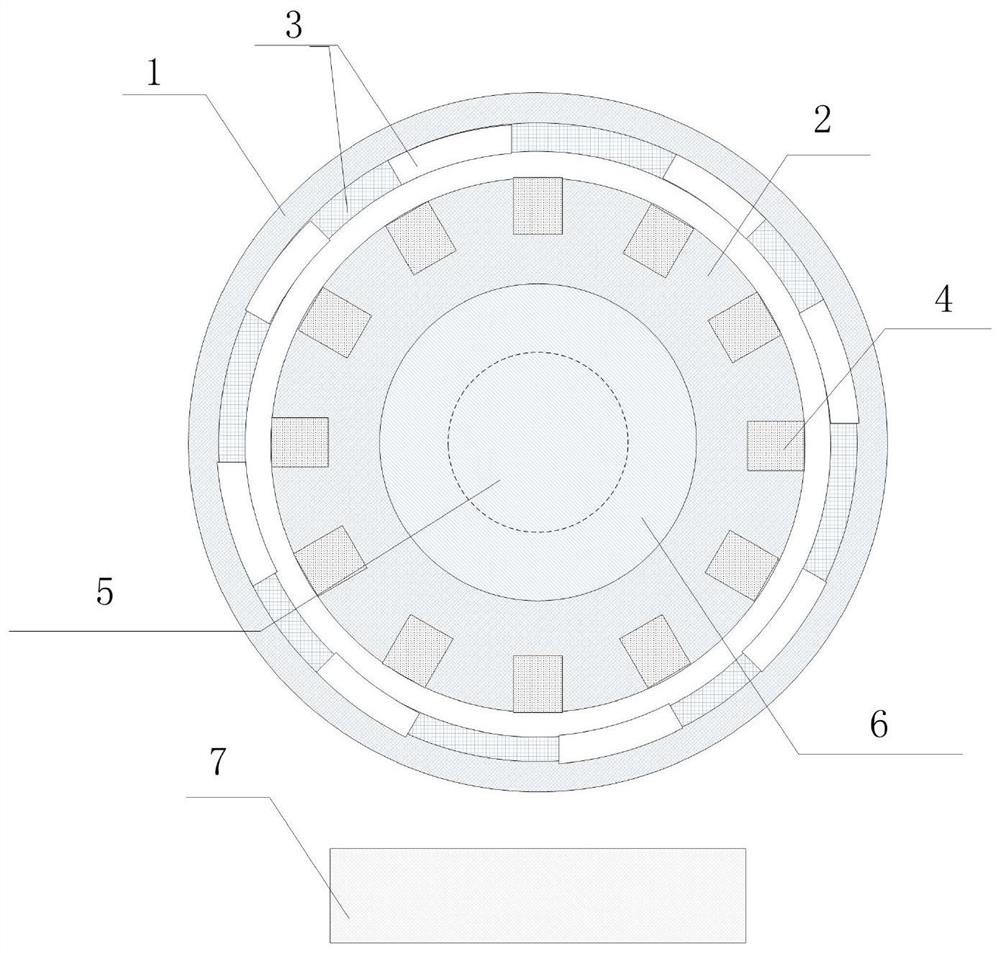

[0054] Such as figure 1 Shown, a kind of torque measuring device, described measuring device comprises:

[0055] Measuring module 7, electromagnetic coupling, driving end 5, driven end 6;

[0056] The electromagnetic coupling includes a squirrel-cage rotor and a permanent magnet rotor, the squirrel-cage rotor and the permanent magnet rotor are arranged coaxially, and a gap is provided between the squirrel-cage rotor and the permanent magnet rotor;

[0057] One of the squirrel-cage rotor or the permanent magnet rotor is connected to the driving end 5, and the other is connected to the driven end 6; the rotation of the driving end 5 drives the rotation of the driven end 6 ;

[0058] The measuring module 7 is used to obtain the rotational speed of the squirrel-cage rotor and the rotational speed of the permanent magnet rotor, and calculate the driving end 5 and the The torque transmitted between the driven ends 6.

[0059] Such as figure 1 and figure 2 As shown, both the s...

Embodiment 2

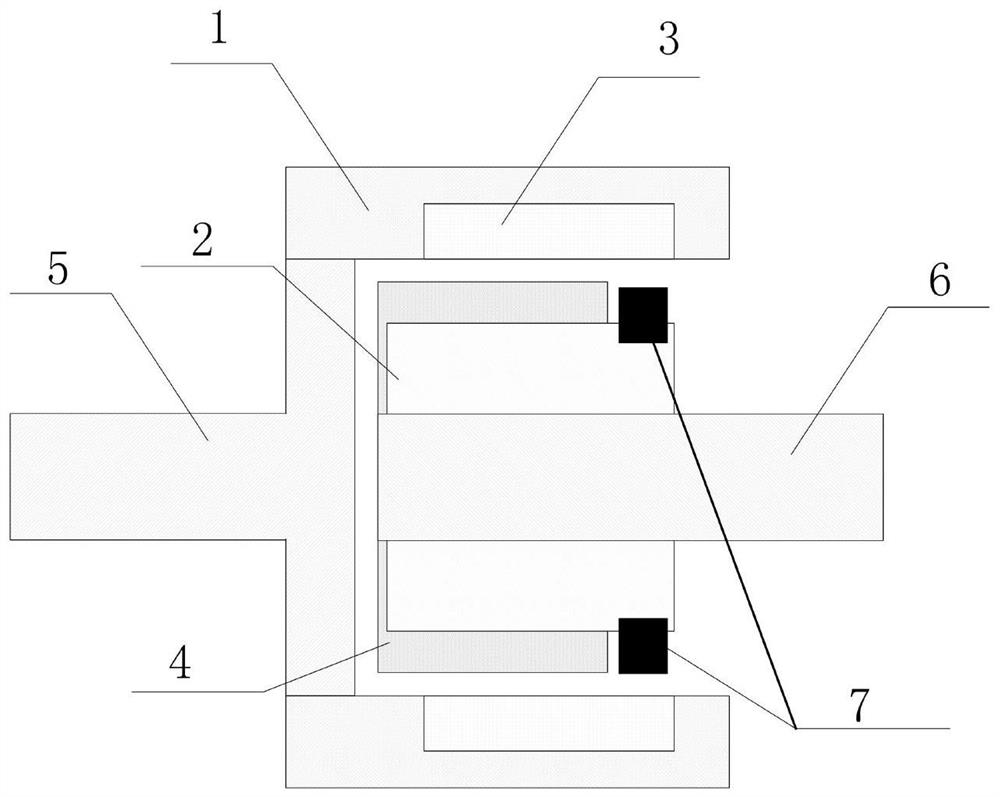

[0084] A torque measuring device, the measuring device comprising:

[0085] Measuring module 7, electromagnetic coupling, driving end 5, driven end 6;

[0086] The electromagnetic coupling includes a squirrel-cage rotor and a permanent magnet rotor, the squirrel-cage rotor and the permanent magnet rotor are arranged coaxially, and a gap is provided between the squirrel-cage rotor and the permanent magnet rotor;

[0087] One of the squirrel-cage rotor or the permanent magnet rotor is connected to the driving end 5, and the other is connected to the driven end 6; the rotation of the driving end 5 drives the rotation of the driven end 6 ;

[0088] The measurement module 7 is connected with the squirrel-cage rotor and the permanent magnet rotor, and the measurement module 7 is used to acquire the rotational speed of the squirrel-cage rotor and the rotational speed of the permanent magnet rotor, and according to the The rotation speed of the cage rotor and the rotation speed of t...

Embodiment 3

[0110] A torque measuring device, the measuring device comprising:

[0111] Measuring module 7, electromagnetic coupling, driving end 5, driven end 6;

[0112] The electromagnetic coupling includes a squirrel-cage rotor and a permanent magnet rotor, the squirrel-cage rotor and the permanent magnet rotor are arranged coaxially, and a gap is provided between the squirrel-cage rotor and the permanent magnet rotor;

[0113] One of the squirrel-cage rotor or the permanent magnet rotor is connected to the driving end, and the other is connected to the driven end; the rotation of the driving end drives the rotation of the driven end;

[0114] The measurement module 7 is connected with the squirrel-cage rotor and the permanent magnet rotor, and the measurement module is used to acquire the rotation speed of the squirrel-cage rotor and the rotation speed of the permanent-magnet rotor, and according to the Calculate the torque transmitted between the driving end 5 and the driven end 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com