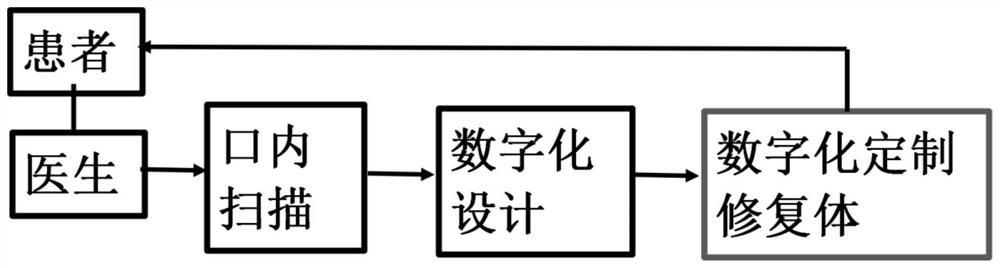

A method for digitally and precisely fabricating dental restorations

A prosthesis, dental technology, applied in the direction of dental prosthesis, dentistry, medical science, etc., can solve the problems of inability to achieve a complete digital process, high technical sensitivity, difficult to control accuracy and reliability, etc., to improve the medical experience and improve the accuracy and reliability, the effect of reducing chair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] 1. Preparation of crown plate:

[0037] In order to confirm the correct shape, color, occlusal and adjoining relationship of the denture and the shape required for the early healing of the gingiva through the crown, to achieve temporary restoration-protection, maintenance and stability; resins with appropriate strength, toughness and hardness must be used , wax and other materials, and these materials must be non-porous and dense materials.

[0038] 1.1 Preparation of polymethyl methacrylate (PMMA) resin disc

[0039] Polymethylmethacrylate (PMMA) resin discs (diameter 98mmx15mm, 98mmx20mm, 98mmx25mm, 98mmx30mm, etc.) were prepared by injection molding. Injection molding using suspension polymerization The pellets of the obtained PMMA are molded on a common plunger or screw injection molding machine. The following are PMMA injection molded Typical process condition. Table 2 is the screw injection molding machine and plunger injection molding machine Process par...

Embodiment 1

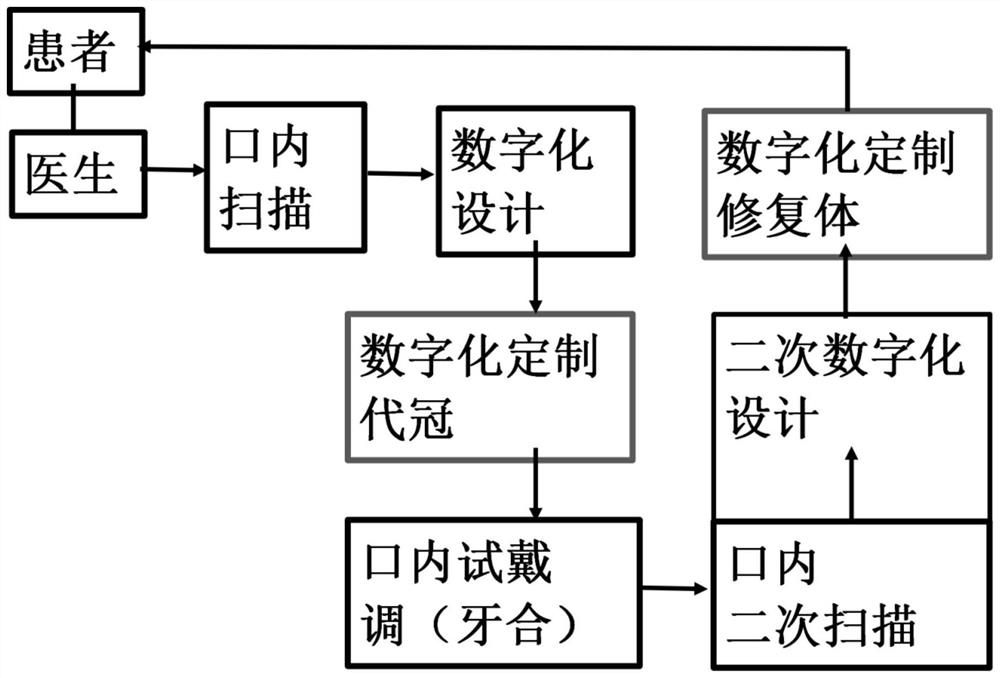

[0047] Example 1. Glazed zirconium dentures, 4-unit bridge of posterior teeth, intraoral scanning, remote design of digital models, chairside fabrication of resin occlusal models, remote fabrication of glazed zirconium restorations;

[0048] Step 1: Accurate acquisition of digital data: On the hospital side, the hospital technician uses a mouth scanner to scan the patient's upper and lower dentition, missing posterior teeth, gums and occlusal relationship to obtain data, and through the colorimeter, standard colorimetric Board and computer intelligent color comparison to obtain the matching color of the patient's teeth and take pictures to obtain pictures of the teeth;

[0049] Step 2: Accurate digital design of the 4-unit bridge of the posterior teeth: input the digital file of the missing anterior teeth obtained in step 1 into the digital CAD design software for dental restorations, and the designer accurately designs the digital crown of the dental restoration of the 5-unit ...

Embodiment 2

[0055] Example 2. Glass-ceramic dentures, single crowns on anterior teeth, intraoral scanning, digital chairside design, resin occlusion chairside fabrication, and restoration chairside fabrication;

[0056]Step 1: Accurate acquisition of digital data: On the hospital side, hospital technicians use a mouth scanner to scan the patient's upper and lower dentition, missing front teeth, gums and occlusal relationship to obtain data, and use a colorimeter, standard colorimeter Board and computer intelligent color comparison to obtain the matching color of the patient's teeth and take pictures to obtain pictures of the teeth;

[0057] Step 2: Accurate digital design of the anterior single crown: input the digital file of the missing anterior tooth obtained in step 1 into the digital CAD design software for dental restorations, and the designer accurately designs the digital crown of the anterior single crown dental restoration; design Documentation includes crown morphology, margina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com