Mounting structure of suspended monorail freight train equipment

A technology for freight trains and installation structures, which is applied in the elevated railway system, transportation and packaging, and locomotives with suspended vehicles, and can solve the problems of unsuitable suspended monorail trains, complicated assembly process, and long assembly production cycle. Achieve the effects of shortening the production cycle, simple assembly process, and short assembly production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

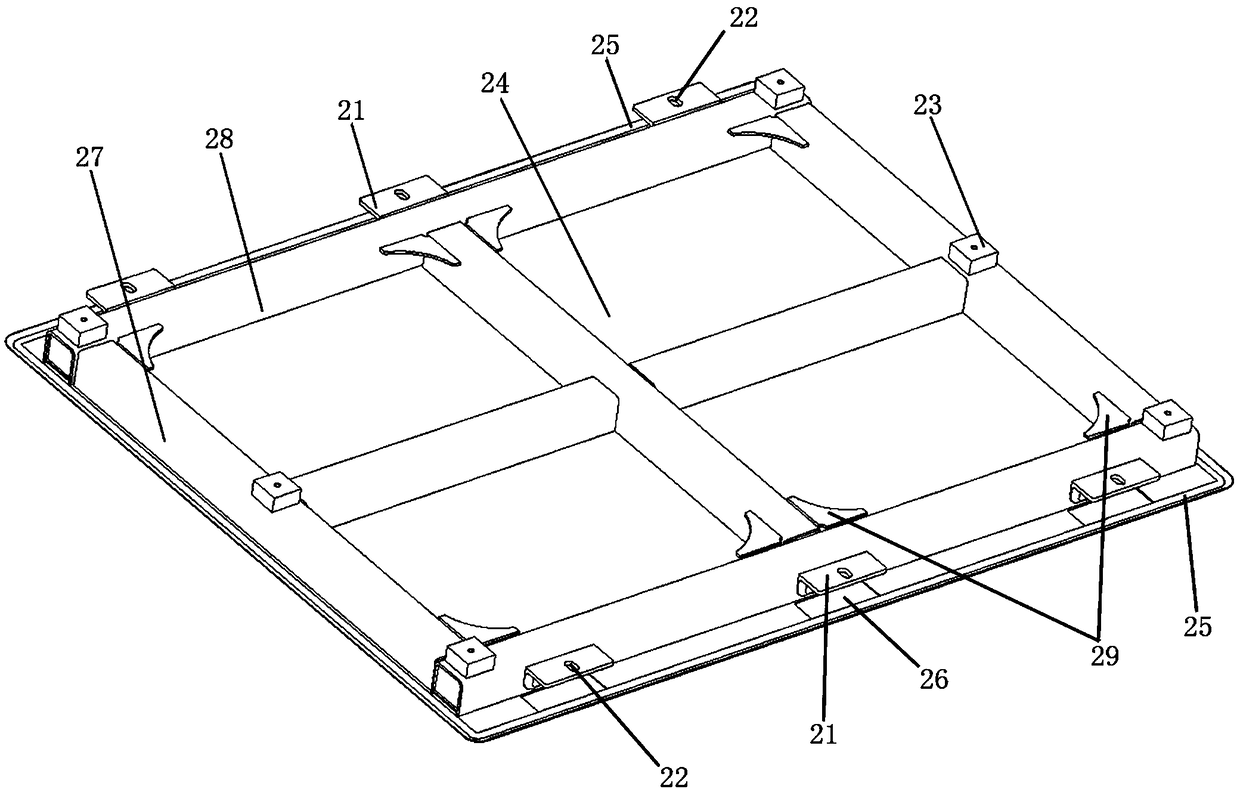

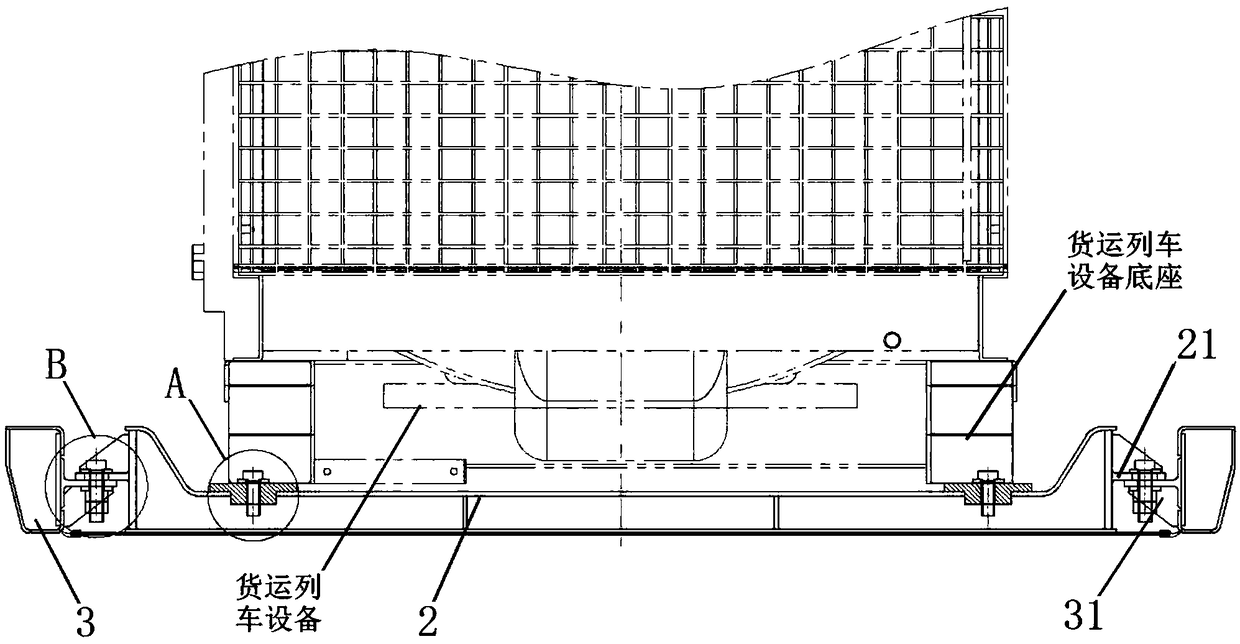

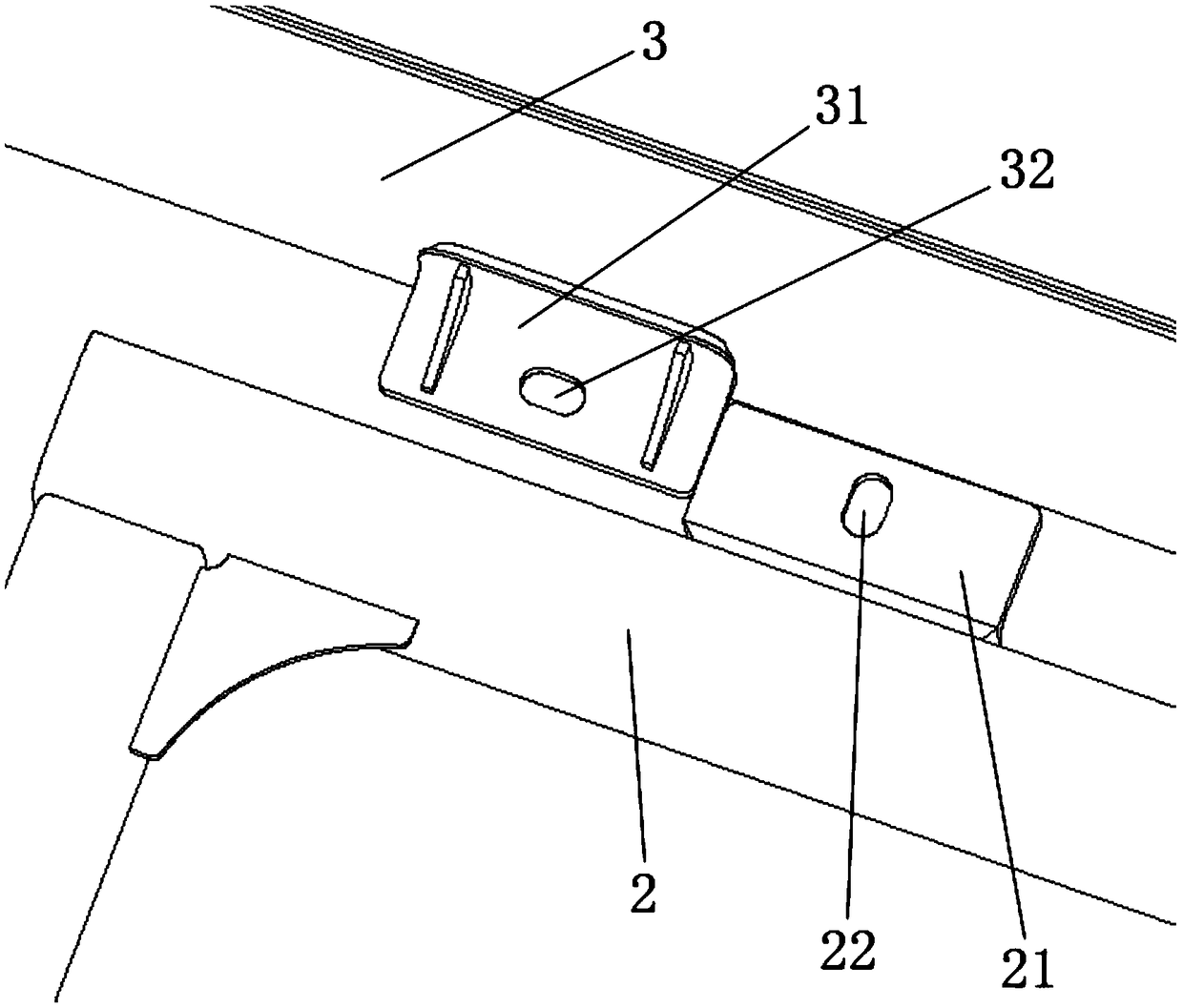

[0028] Such as Figure 1-5 As shown, the installation structure of a suspended monorail freight train equipment provided by the present invention has simple structure, scientific and reasonable design, convenient use, simple assembly process, short assembly production cycle and high assembly efficiency, and can be applied to suspended monorail Installation of equipment on trains. The present invention comprises an integral car roof 1 welded to the two side walls of the frame of a freight train on both sides, an equipment mounting frame 2 that can be detachably connected to the integral car roof 1 and freight train equipment, freight train equipment and equipment After the installation frame 2 is installed, it is integrally installed on the integral roof 1. The t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap