Fast operation road sweeper

A technology for fast operation and road sweeper, applied in road cleaning, construction, cleaning methods, etc., can solve the problems of difficult to increase the operating speed, poor spray dust reduction effect, dust, and fuel consumption restrictions, to increase the volume and improve the gravity. The effect of dust removal efficiency and reduction of maintenance difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

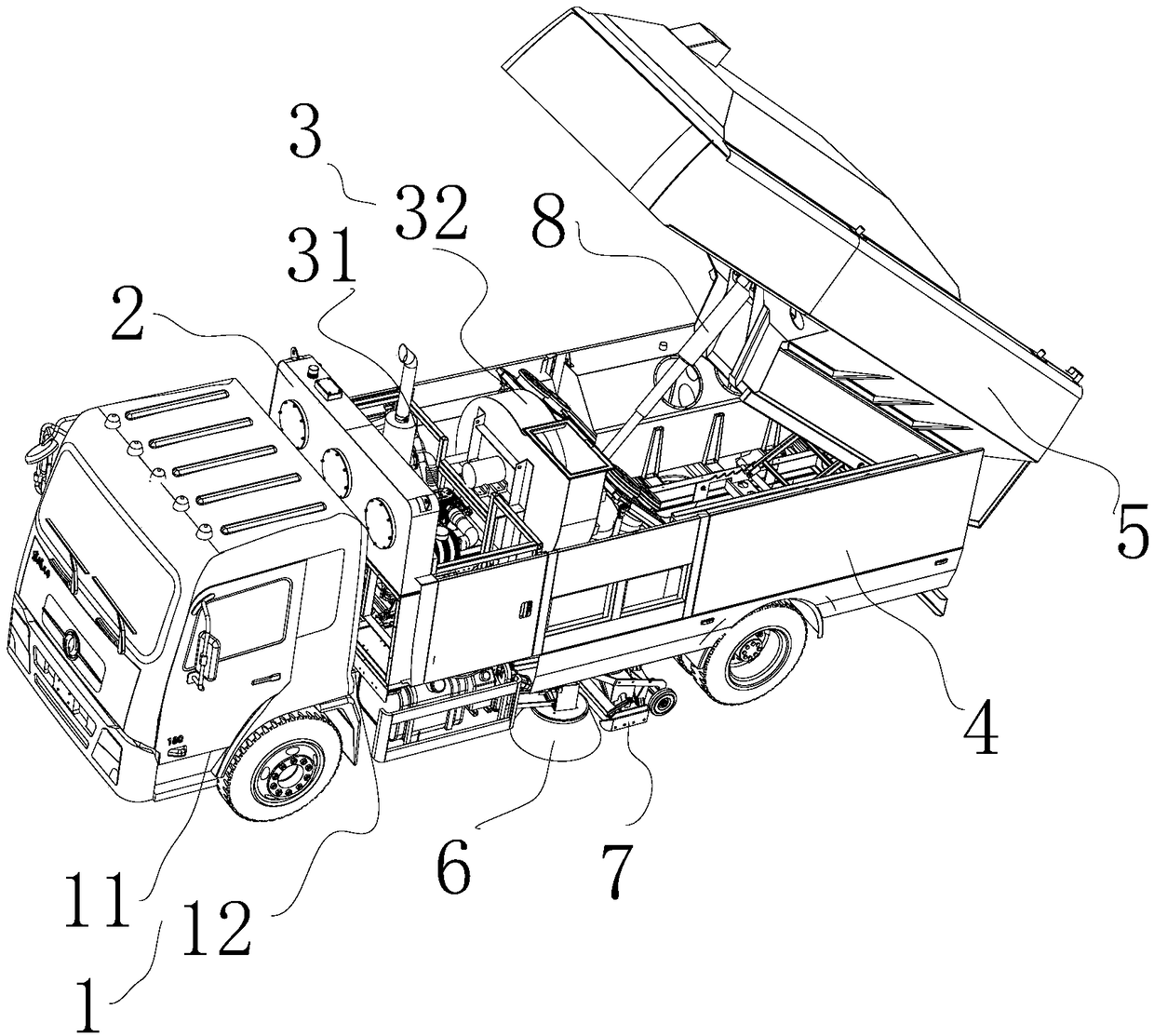

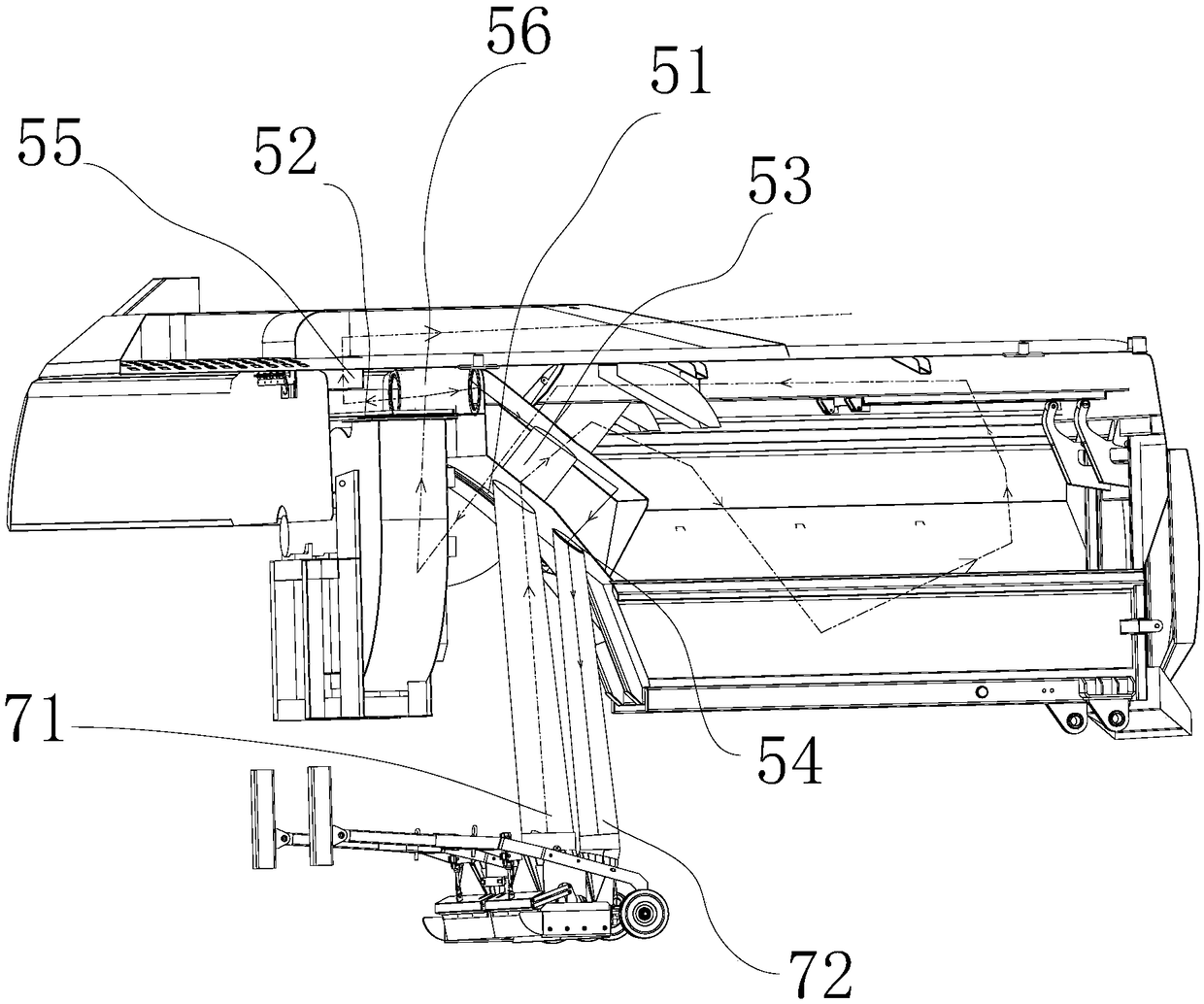

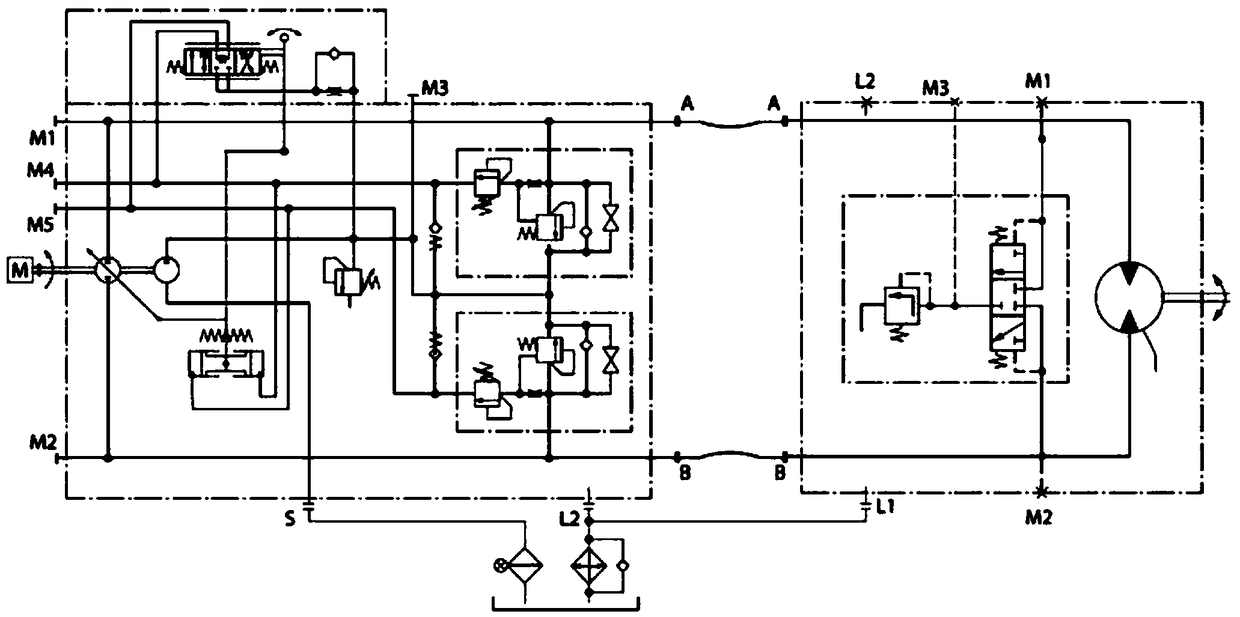

[0020] like Figure 1~3 It is a preferred solution of the present invention, including a second-class chassis 1, a hydraulic oil tank 2, a power system 3, a fresh water tank 4, a trash can 5, a sweeping plate 6, a suction nozzle 7 and a lifting cylinder 8,

[0021] The second type of chassis 1 is a large chassis with a total mass of more than 10 tons, including the cab 11 and the girder 12, the hydraulic oil tank 2, the power system 3, and the clean water tank 4 are laid out from front to back through the sub-frame (not shown in the figure) Above the girder 12 of the second type chassis 1, the dustbin 5 is arranged above the hydraulic oil tank 2, the power system 3 and the clean water tank 4. The sweeping plate 6 and the suction nozzle 7 are arranged under the girder 12, the sweeping plate 6 is set under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com