Sound absorbing device

A sound-absorbing device and sound-absorbing technology, which is applied in the field of noise reduction, can solve problems such as poor sound-absorbing performance of porous sound-absorbing materials, inability to effectively control sound waves, and a large range of influence, so as to improve sound-absorbing performance, increase sound-absorbing, Good sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0047] refer to figure 1 , As an embodiment of the present invention, the porous sound-absorbing device 1 of the present invention includes one or more than two porous sound-absorbing layers; the porous sound-absorbing layers can be connected by bonding. The porous sound-absorbing layer of the present invention is a porous sound-absorbing material, which can be glass fiber cotton, melamine foam, polyurethane fiber or polyurethane foam; but is not limited to the above types, and can be any porous sound-absorbing material. The sound absorption of more than two porous sound-absorbing layers is closely related to the numerous fine pores inside the porous sound-absorbing layer. The pores are connected to each other and extend to the outer surface to connect with the outside world. Two parts, one of which is reflected and reflected into the adjacent porous sound-absorbing layer, and the remaining part is transmitted to the inside of the porous sound-absorbing layer, and the sound wa...

Embodiment 1

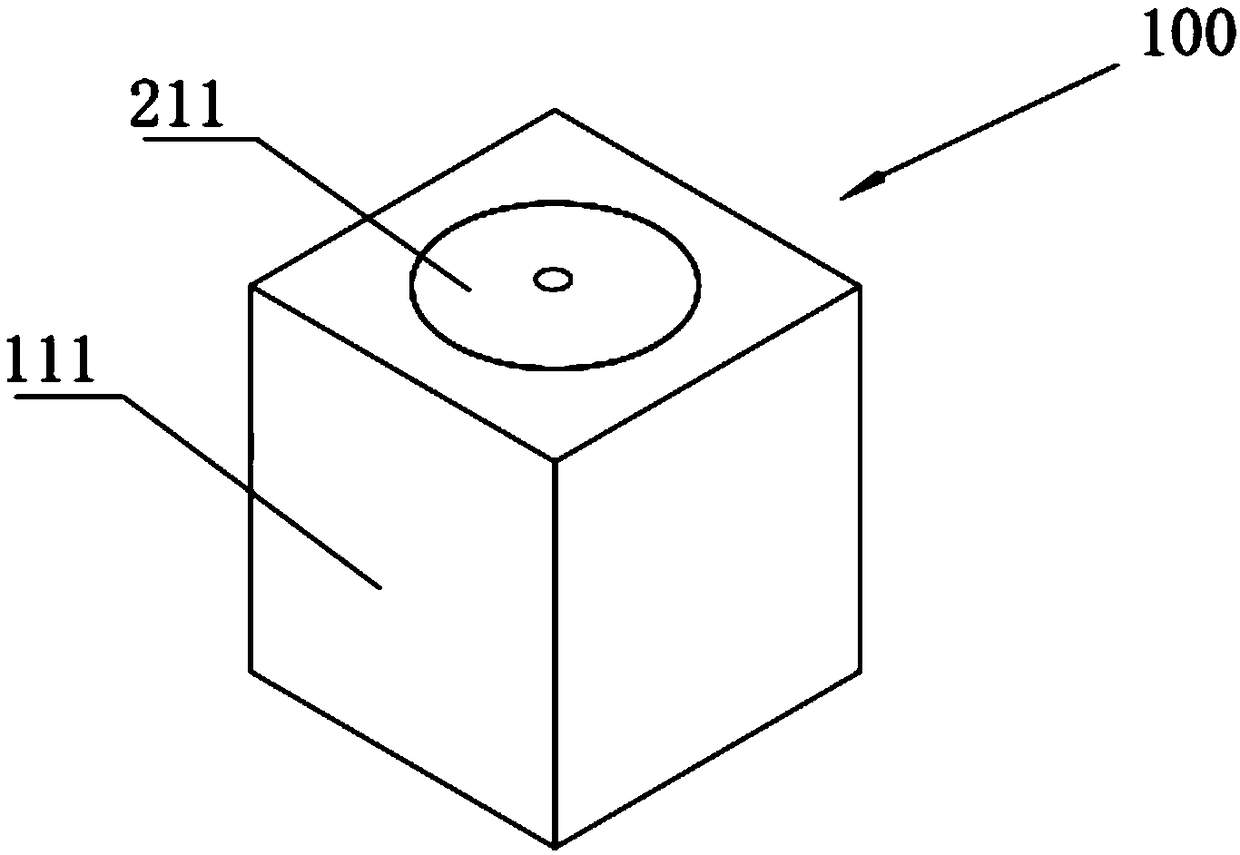

[0077] see figure 1 , the sound-absorbing unit body 100 includes a porous sound-absorbing device 1 and a resonant sound-absorbing device 2,

[0078] The porous sound-absorbing device 1 includes a first porous sound-absorbing layer 111, the material of the first porous sound-absorbing layer 111 is glass fiber cotton; the length and width of the first porous sound-absorbing layer 111 are 120mm, The thickness of the first porous sound-absorbing layer 111 is 70mm, and the density is 10Kg / m 3 , the flow resistance rate is 3175N·s / m 4 .

[0079] The first porous sound-absorbing layer 111 is provided with a lumen 14, and the corresponding lumen 14 is a first resonant tube 211; the first resonant tube 211 is embedded in the first porous sound-absorbing layer 111;

[0080] The first resonance tube 211 is a cylindrical tube with a diameter of 40 mm, a height of 70 mm, and a thickness of 1 mm;

[0081] The top of the first resonant tube 211 is provided with a through hole, and the so...

Embodiment 2

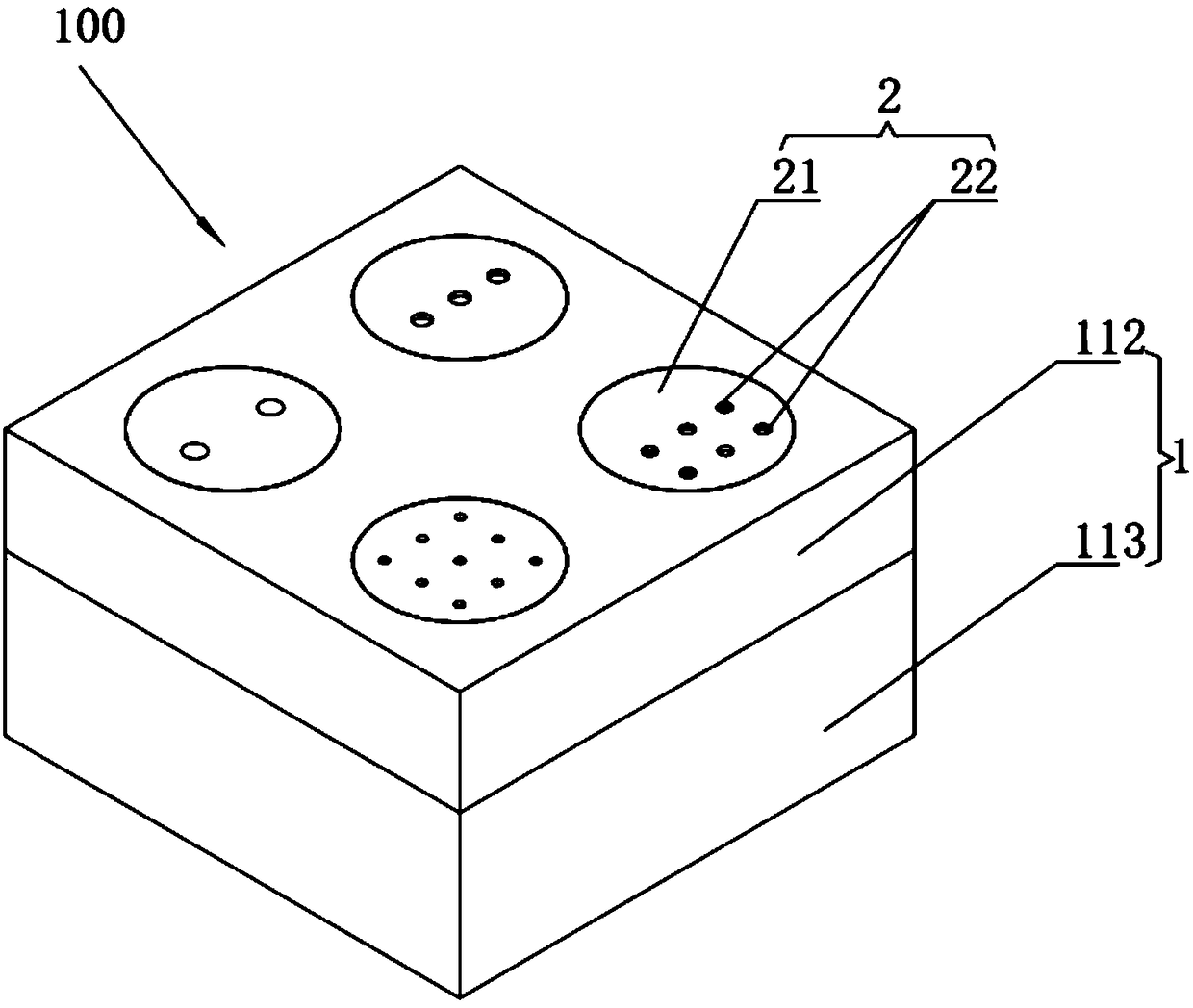

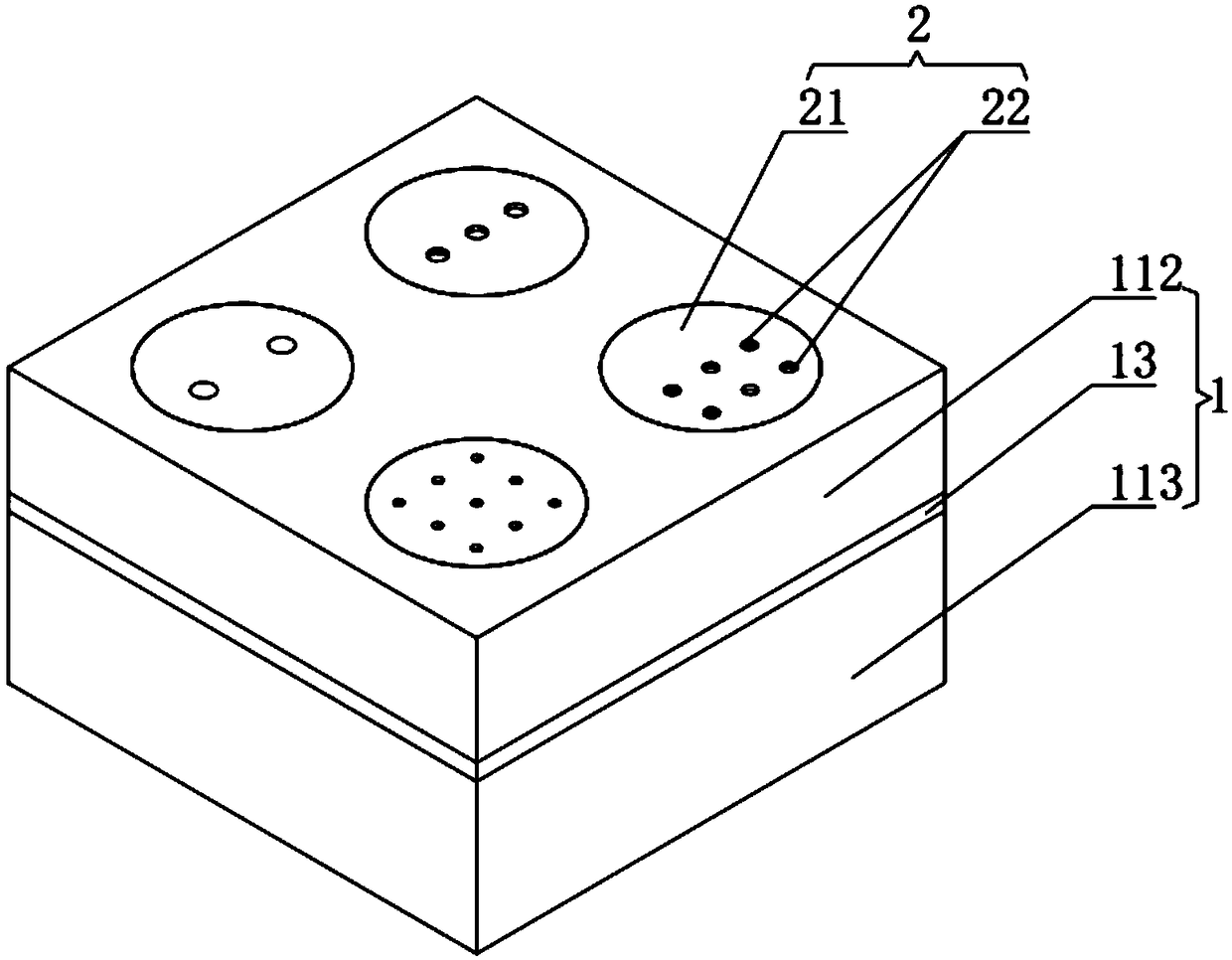

[0083] see figure 2 , Figure 10 and Figure 11 , different from Embodiment 1, the sound-absorbing unit body 100 includes a porous sound-absorbing device 1 and a resonant sound-absorbing device 2, and the porous sound-absorbing device 1 includes a second porous sound-absorbing layer 112 and a third porous sound-absorbing layer 112 sound-absorbing layer 113 . The second porous sound-absorbing layer 112 and the third porous sound-absorbing layer 113 are bonded by glue.

[0084] The material of the second porous sound-absorbing layer 112 is melamine foam; the length and width of the second porous sound-absorbing layer 112 are 120mm, the thickness of the second porous sound-absorbing layer 2 is 20mm, and the density is 10Kg / m 3 , the flow resistance rate is 4200N·s / m 4.

[0085] The material of the third porous sound-absorbing layer 113 is polyurethane fiber; the length and width of the third porous sound-absorbing layer 113 are 120mm, the thickness of the third porous sound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com