Simple cycle engine with combustion chamber driven compressor by continuously variable transmission

A continuously variable transmission and simple cycle technology, which is applied in the direction of machines/engines, gas turbine devices, mechanical equipment, etc., can solve the problems of low miniaturization efficiency, insufficient efficiency, and many parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

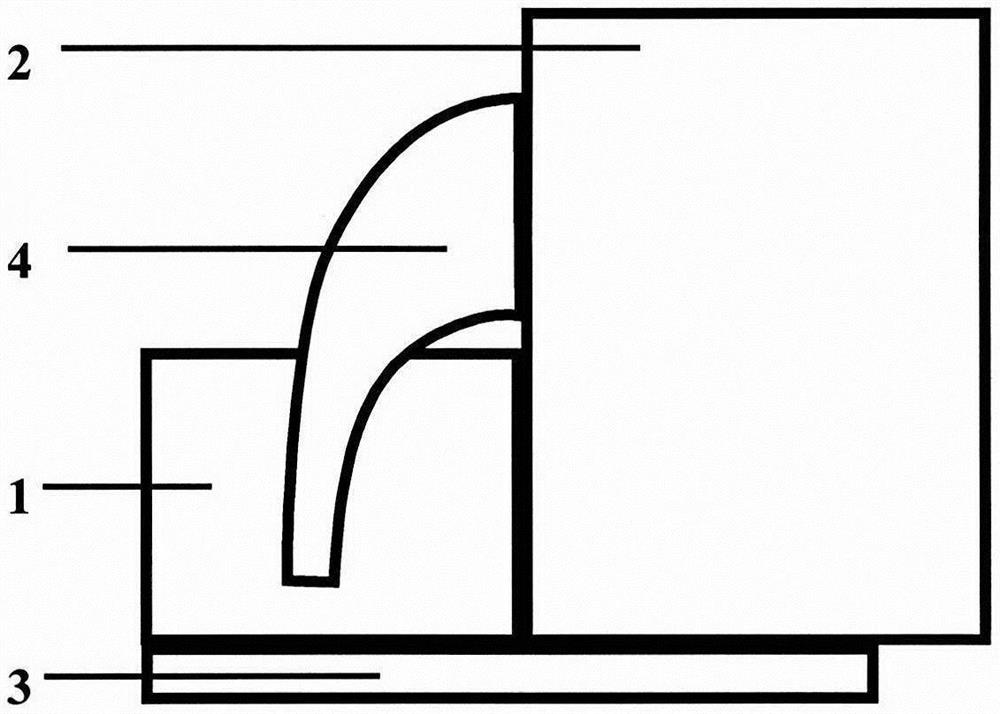

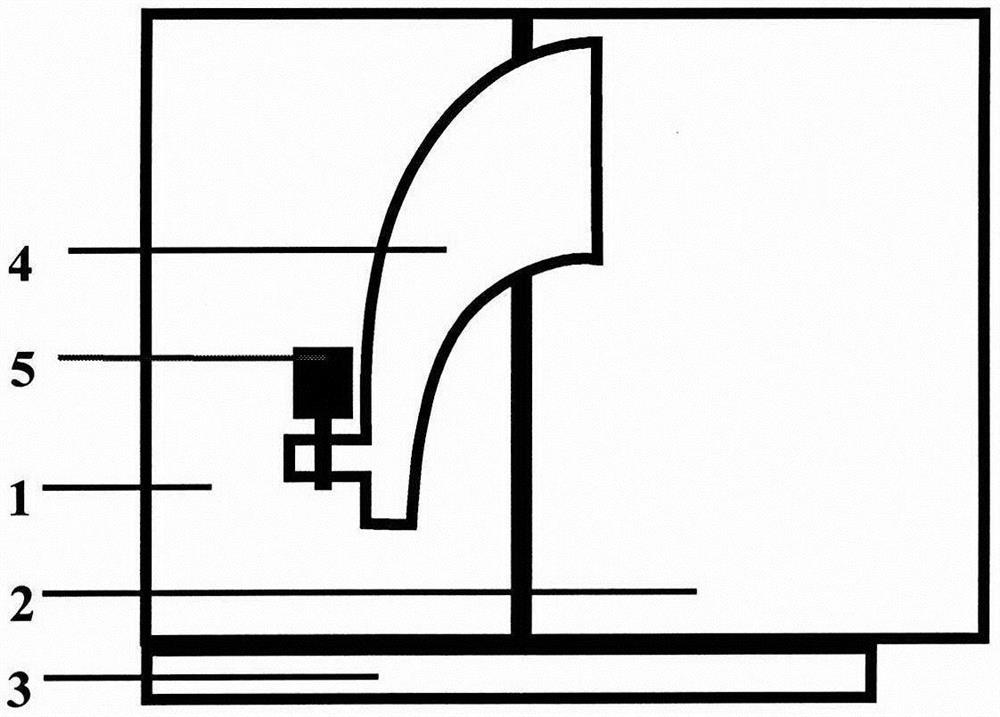

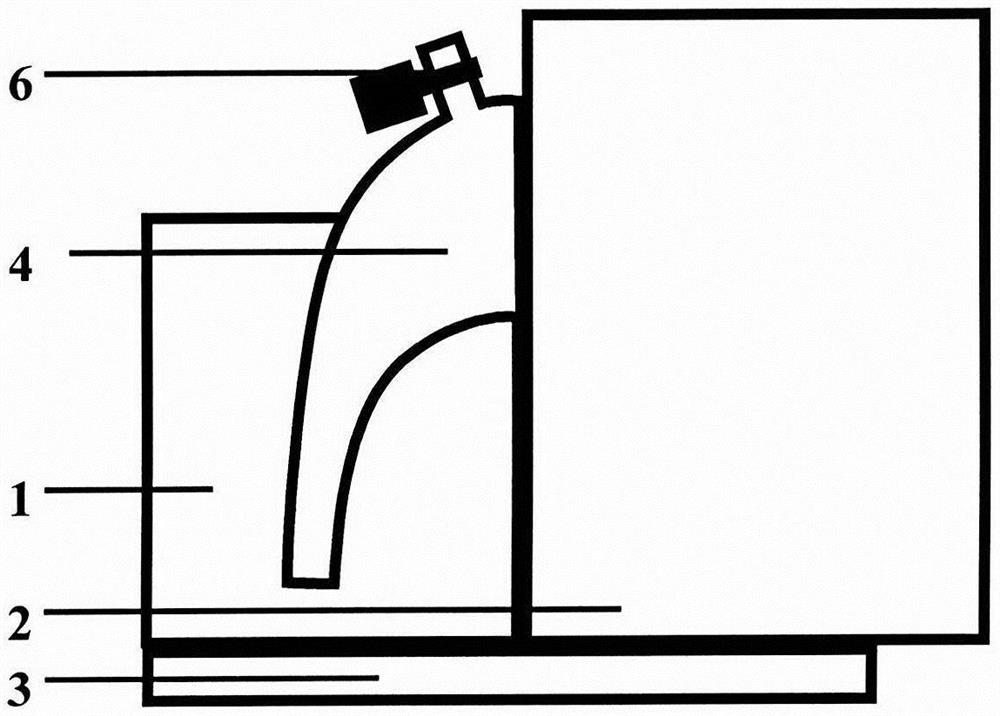

[0038] figure 1 , 2 , 3, the compressor (1) and the wind-driven motor (2) in the basic work system can adopt various compressors and wind-driven motors that can continuously produce or consume compressed air or consume gas, such as star piston compressors, Sliding vane compressors, scroll compressors, centrifugal compressors, axial flow compressors, mixed flow compressors, etc., various volume and speed compressors, and the wind engine corresponds to star piston air Engine, sliding vane rotor wind engine, vortex wind engine, centrifugal wind engine, axial flow wind engine, mixed flow wind engine, etc. various volume and speed wind engines; The type of compressor (1) and the type of wind-driven engine (2) are matched according to different situations. For example, small and medium-sized engines can choose volumetric scroll compressors, sliding vane compressors, etc. Engines, sliding vane rotor wind engines, etc. are self-matched or mixed and matched. In addition to the volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com