The gear and the rack reciprocate to the end point automatic limit device

An automatic limit and reciprocating motion technology, applied in the direction of transmission, friction transmission, belt/chain/gear, etc., can solve the problems of no substance, too simple setting, weakened rack toughness, etc., and achieve easy maintenance and sealing , simple structure and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

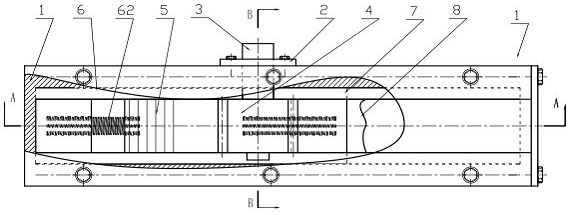

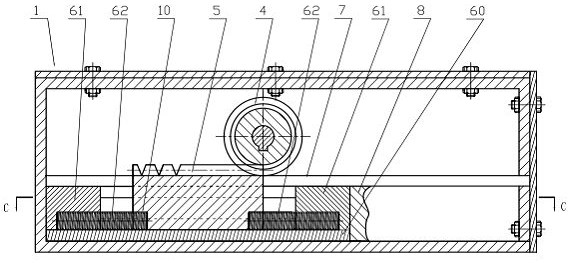

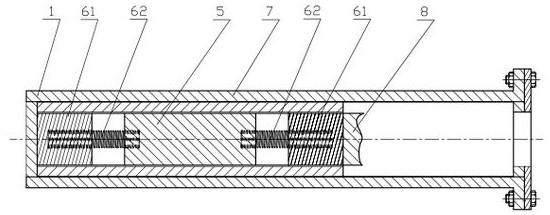

[0029] The specific embodiment of the present invention is described below in conjunction with accompanying drawing, as figure 1 , figure 2 , image 3 , Figure 4 Shown: the gear and the rack reciprocate to the end of the automatic limit device, including the housing 1, the fixed seat 2, the main shaft 3, the gear 4, the rack 5, the automatic limit drive block 6, the fixed slideway 7 and the dragging object 8.

[0030] The housing 1 is a sealed housing, and the main body structure of the housing 1 is set as a square, and can also be set as a circle or other shapes. One side of the housing 1 is provided with a fixing seat 2, and the fixing seat 2 passes through the The screw is fixedly connected to the housing 1, the fixed seat 2 is fixedly connected to the main shaft 3, and the main shaft 3 passes through the housing 1 and is fixedly connected to the gear 4, and the main shaft 3 provides power for the rotational movement of the gear 4 by connecting an electric or manual de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com