Smelting equipment for artificial fur processing production

A technology of artificial plush and smelting equipment, applied in lighting and heating equipment, crucible furnaces, furnaces, etc., can solve the problems of occupying the space of the liquid storage device, inconvenient unloading of the furnace body, and deterioration of the solution, so as to achieve easy movement, Improve the purity and product quality, reduce the effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

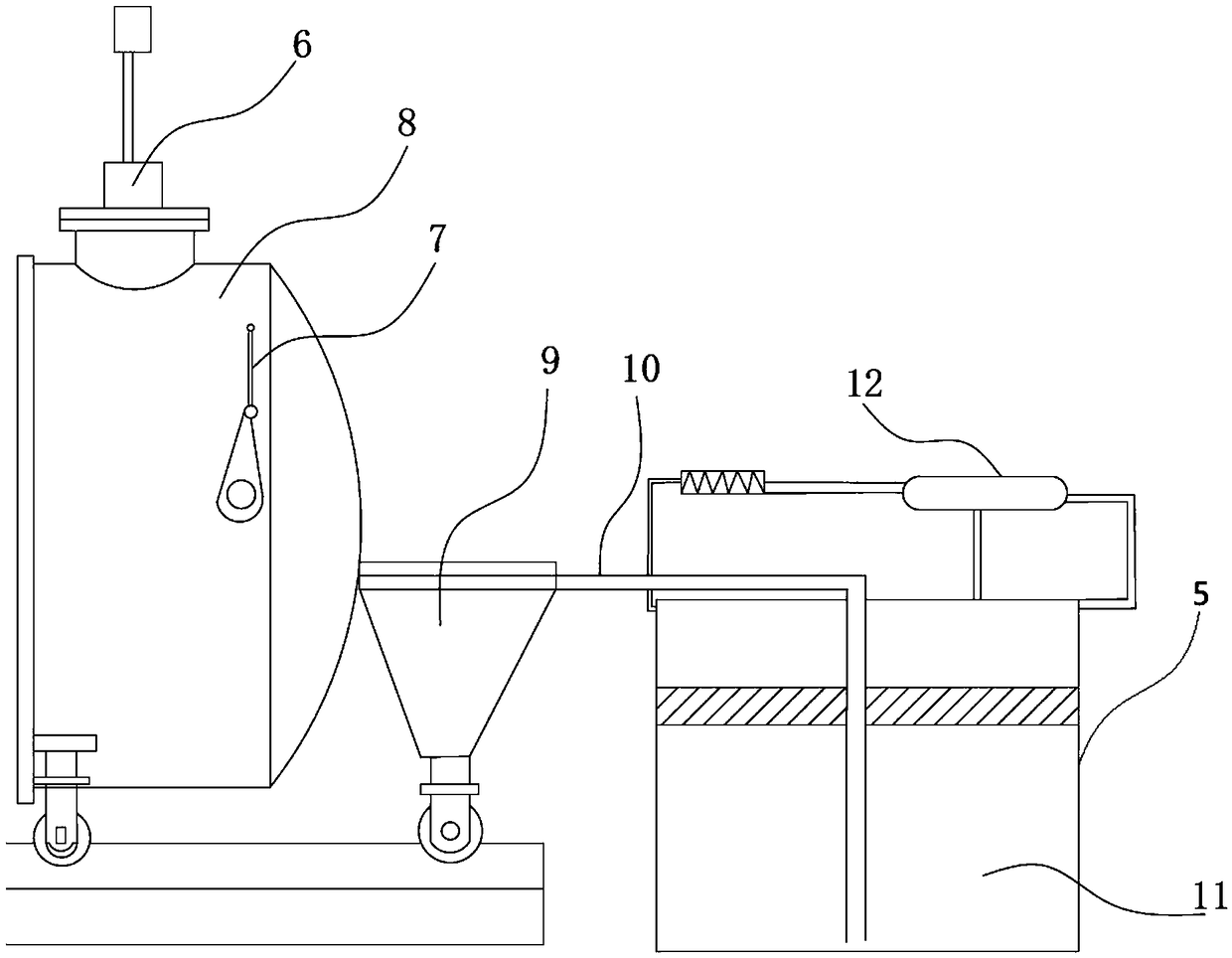

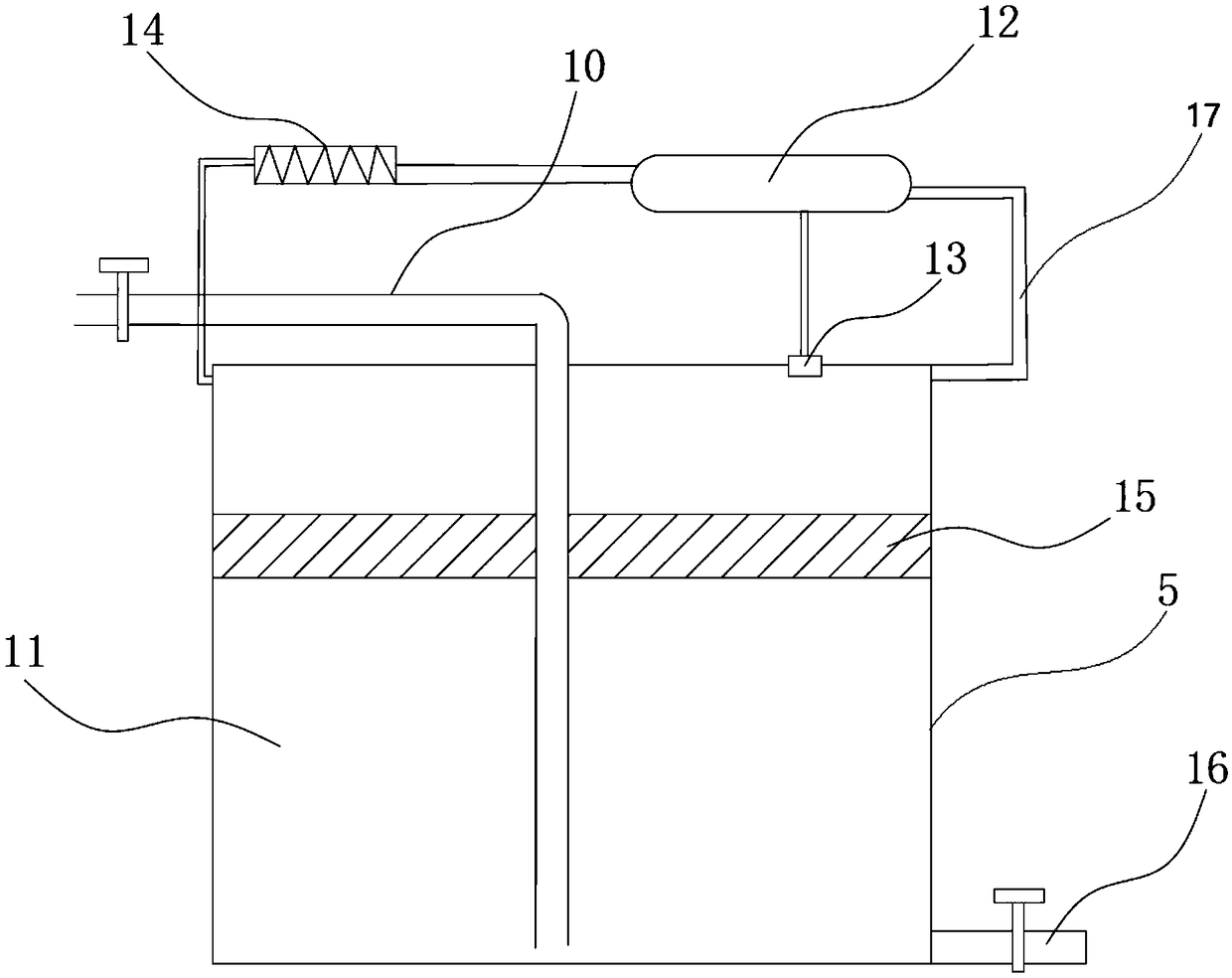

[0027] refer to figure 1 , figure 2 As shown, the smelting equipment for the production of artificial plush is composed of a furnace body 8, an infusion device 9 and a solution tank 5, and the infusion device 9 is located between the furnace body 8 and the solution tank 5, and the furnace body 8 is cylindrical, one side of the furnace body 8 is an arc surface, and the other side of the furnace body 8 is a vertical surface. The upper end of the furnace body 8 is provided with a feeding device 6, and the charging device 6 is installed on the furnace body 8 on the upper port;

[0028] The infusion device 9 is funnel-shaped, and the infusion device 9 is a closed structure, and the upper end side of the infusion device 9 is provid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap