Perovskite solar cell structure

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor stability and high cost of production materials for perovskite solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

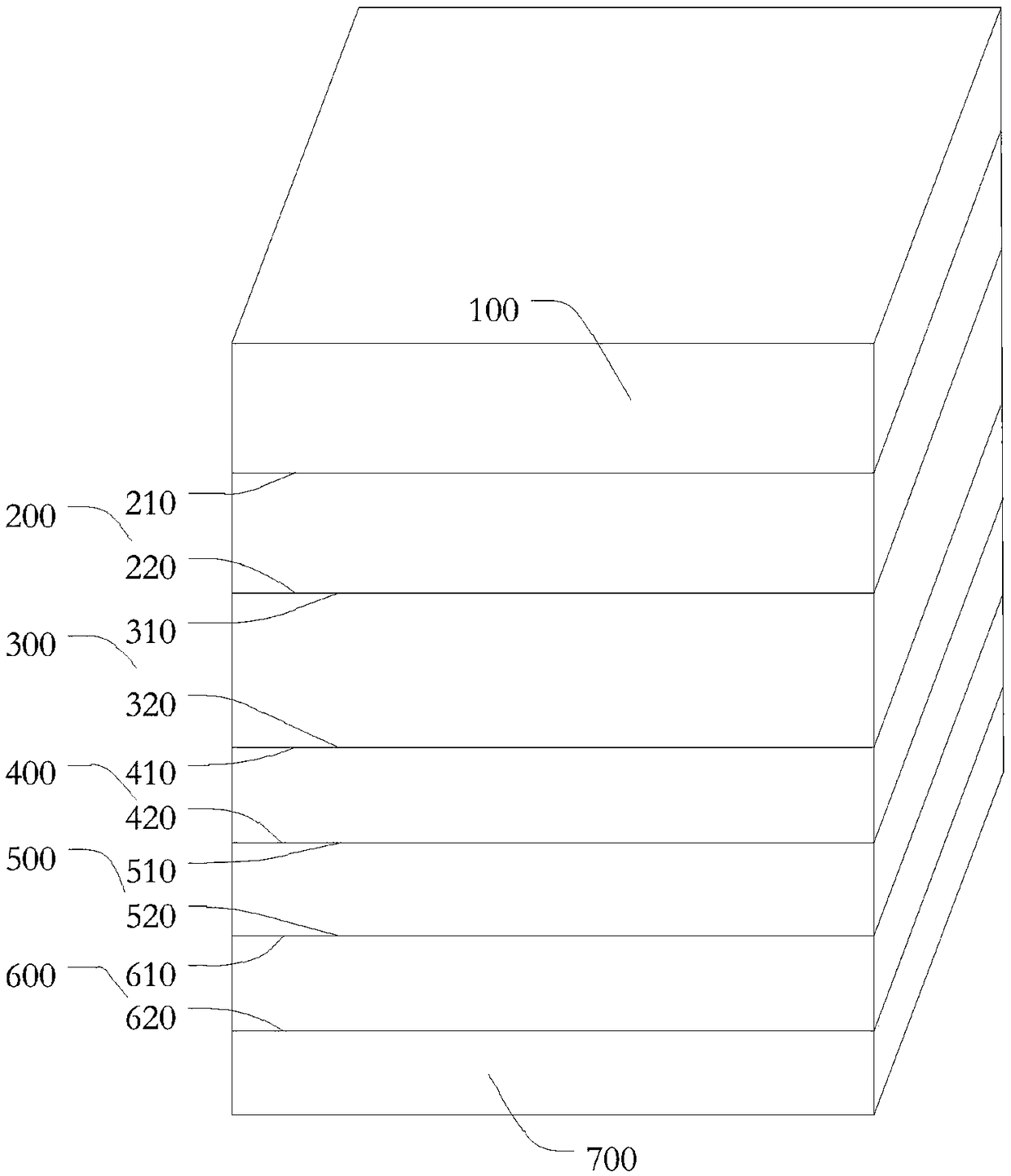

[0029] See figure 1 , figure 1 It is a schematic diagram of the overall structure of a perovskite solar cell provided by an embodiment of the present invention. The embodiment of the present invention provides a perovskite solar cell, and the perovskite solar cell includes an inert semi-metal electrode layer 100, an electron transport layer 200, the perovskite film layer 300, the hole transport layer 400, the transparent conductive electrode 500 and the glass substrate 600, the inert semi-metal electrode layer 100, the electron transport layer 200, the perovskite film layer 300, the hole transport layer Layer 400, transparent conductive electrode 500 and glass substrate 600 are described in detail below:

[0030] For the inert semi-metal electrode layer 100:

[0031] The material for making the inert half-metal electrode layer 100 may be Bi element; or, the material for making the inert half-metal electrode layer 100 may be Sb element. The thickness of the inert semi-metal ...

Embodiment 2

[0069] See Figure 9 as shown, Figure 9 It is a flowchart of a method for manufacturing a perovskite solar cell provided by an embodiment of the present invention. Embodiment 2 of the present invention provides a method for manufacturing a perovskite solar cell. The method for manufacturing a perovskite solar cell includes:

[0070] Step S100, obtaining the FTO electrode layer 700, and preparing a glass substrate 600 on the FTO electrode layer 700;

[0071] Specifically, the glass substrate 600 can be prepared on the surface of the FTO electrode layer 700 in an existing conventional manner, for example, the FTO electrode can be coated by spin coating, doctor blade coating or slit coating. Layer 700 is plated on the surface of FTO electrode layer 700 . The FTO electrode layer 700 and the glass substrate 600 can be made parallel to each other. In this way, the technical effect that the FTO electrode layer 700 and the glass substrate 600 can be fabricated sequentially from b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com